Systèmes de distribution de gaz Swagelok®

Les systèmes de distribution de gaz sont essentiels dans nombre d’installations industrielles, laboratoires de recherche ou sites de production. Un acheminement sûr, fiable et efficace des gaz là où on en a besoin est indispensable au bon fonctionnement d’une installation. Les systèmes de distribution de gaz ont pour fonction d’acheminer des gaz de manière sûre et efficace d’une source haute pression jusqu’à l’installation, à la pression et au débit requis par chaque application.

Contacter un spécialisteLes panneaux standard de distribution de gaz Swagelok sont livrés entièrement assemblés et testés. Réunis dans notre guide des applications, ils sont faciles à commander à l’aide d’une référence unique, ce qui réduira le temps nécessaire à vos ingénieurs pour spécifier et acquérir de nouveaux systèmes.

Sur nos panneaux modulaires, nous évitons autant que possible les raccordements filetés afin de limiter le nombre de points de fuite potentiels. Un étiquetage intuitif est par ailleurs apposé sur les panneaux afin d’en sécuriser et d’en simplifier à la fois l’utilisation et la maintenance. Ceux-ci bénéficient en outre de la garantie à vie limitée Swagelok.

En savoir plus sur les systèmes de distribution de gaz Swagelok®

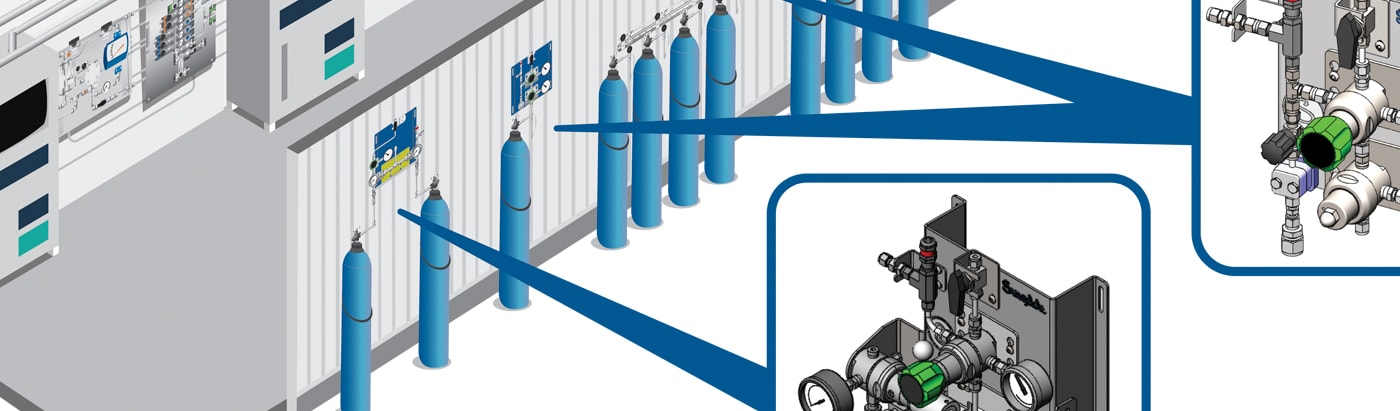

Les systèmes de distribution de gaz Swagelok sont construits autour d’une ou de plusieurs étapes de régulation de la pression et peuvent comporter les quatre sous-systèmes suivants :

- Dispositif de raccordement à la source (DRS) Swagelok®

- Panneau de régulation de gaz (PRG) Swagelok®

- Centrale de commutation automatique (CCA) Swagelok®

- Dispositif de régulation au point d’utilisation (DRPU) Swagelok®

Dispositif de raccordement à la source (DRS) Swagelok®

Ce dispositif raccorde la source de gaz haute pression au système de distribution. Il est important qu’il comporte les composants (raccords bouteille, flexibles, tubes, filtres) et les fonctions (évent, purge, décharge) nécessaires pour faire en sorte que le gaz atteigne en toute sécurité le dispositif de régulation primaire ou une centrale de commutation automatique. Pour une seule bouteille de gaz, l’assemblage pourra se limiter à un simple flexible équipé d’un connecteur, tandis qu’un manifold comportant de multiples vannes et flexibles sera nécessaire s’il y a plusieurs bouteilles. Swagelok propose des options largement configurables pour purger ou évacuer les gaz lors d’un changement de bouteille – afin de toujours garantir la sécurité de l’opérateur – et offre en outre la possibilité d’évacuer le gaz de chaque ligne afin de maximiser la disponibilité.

Des conseillers Swagelok s’assureront qu’il ne manque aucun composant, que ceux-ci ont été correctement choisis de manière à limiter le nombre de raccordements, que les flexibles ne tombent pas au sol et que les supports sont en nombre suffisant. Nous pouvons également vous renseigner sur les gaz susceptibles d’imposer l’utilisation de flexibles particuliers.

Panneau de régulation de gaz (PRG) Swagelok®

Le PRG effectue la première détente du gaz provenant de la source et s’assure que le gaz est acheminé au bon débit jusqu’au prochain élément du système. L’abaissement de la pression est réalisé soit en une fois à l’aide d’un détendeur unique, soit en deux étapes à l’aide d’un dispositif à double détente.

Swagelok propose des panneaux modulaires faciles à entretenir, dont chaque pièce peut être démontée au niveau d’un raccordement, de sorte que le panneau n’a jamais besoin d’être extrait intégralement du système. Swagelok propose également en option un codage par couleurs du régulateur et des vannes si cela est nécessaire sur votre site. Swagelok peut également vous aider à voir où il est nécessaire d’installer un détendeur à double détente.

Centrale de commutation automatique (CCA) Swagelok®

La centrale de commutation automatique permet de basculer d’une source de gaz sur une autre sans interrompre l’alimentation. Le dispositif fonctionne avec deux régulateurs de pression dont les points de consigne sont décalés, de sorte que le système continue à fonctionner pendant le basculement d’une source de gaz sur l’autre. La centrale de commutation permet de fixer les points de consigne de manière à limiter la quantité de gaz restante dans les bouteilles.

En plus de garantir un point de basculement constant, le dispositif permet une régulation facultative de la pression en ligne si votre système comporte un régulateur en aval au point d’utilisation, ce qui permet d’éliminer le coût supplémentaire d’un régulateur au niveau de la CCA. Des spécialistes Swagelok peuvent aider votre équipe à mieux comprendre les fonctionnalités du système, à remédier à d’éventuels problèmes et à assurer la continuité des opérations.

Regarder une démonstration de la CCA

Dispositif de régulation au point d’utilisation (DRPU) Swagelok®

Le point d’utilisation correspond à la dernière étape dans la régulation de la pression du gaz avant que celui-ci ne soit utilisé. Le dispositif comporte généralement un régulateur de pression, un manomètre et une vanne d’isolement. Un DRPU offre un moyen pratique pour régler précisément la pression en fonction des besoins du banc d’essai ou de l’équipement utilisé.

Ce dispositif compact, uniformisé et fiable au point d’utilisation offre plusieurs possibilités de montage : plaque plate, par la base, par le haut ou mural. Un spécialiste Swagelok peut vous indiquer certaines économies à réaliser, par exemple, l’utilisation d’un PRG à simple détente pour réduire les coûts lorsque des variations de la pression dans la ligne entre le PRG et le DRPU sont acceptables.

Guides des applications des systèmes de distribution de gaz

Localisez des informations détaillées sur nos ensembles.

가스 분배 시스템은 각 기계가 요구하는 압력과 흐름율에 맞추어 가스를 고압 가스원에서 시설로 전달하는 것이 목적입니다. 대부분 하나 또는 일련의 압력 제어 단계 주위에 설치되고, 가스 분배 시스템에는 네 가지의 대표적인 서브 시스템이 있습니다. 가스원 입구 연결부, 일차 가스 압력 제어, 자동 변환, 그리고 이용 현장입니다. 이 가이드는 스웨즈락의 가스 분배 시스템에 대한 정보를 제공하고 있습니다.

그랩 샘플링은 분석을 위해 유체 또는 가스 샘플을 실험실에 보내기 위해 해당 샘플을 채취하는 것입니다. 완전하게 문서화된 유체 샘플링 및 제어 시스템을 위해 Swagelok 애플리케이션 솔루션을 사용하면 일관성 있는 운영이 가능합니다.

Comprendre les systèmes de distribution de gaz industriels

Gagnez en productivité dans vos activités en découvrant les critères de conception qui influent le plus directement sur l’efficacité – y compris la facilité d’utilisation et d’entretien – des systèmes de distribution de gaz industriels.

Lire le livre blancDes ressources Swagelok sélectionnées pour vous

Étude de cas : 200 conduites de gaz, 1 solution globale.

Le département recherche et développement d’une grande entreprise chimique britannique utilise divers gaz spéciaux. L’entreprise a profité du programme « Systèmes de distribution de gaz » Swagelok pour améliorer la sécurité de son système et réaliser de nouvelles économies.

Comment réduire vos dépenses en maintenance en améliorant la distribution de gaz

Découvrez comment des panneaux de régulation de gaz faciles à utiliser et un système d’acheminement et de distribution de gaz globalement plus efficace peuvent aider des laboratoires, des raffineries et d’autres installations à réduire leurs dépenses de maintenance.

Q&R : Comment réduire les coûts et améliorer la sécurité grâce à des systèmes de distribution de gaz plus efficaces

Découvrez des problèmes courants qui peuvent nuire à la sécurité et à l’efficacité des systèmes de distribution de gaz ainsi que l’intérêt à long terme d’une évaluation de ces systèmes réalisée par des spécialistes.

Améliorer la sécurité et l’efficience des systèmes de distribution de gaz

Les systèmes de distribution de gaz contribuent de manière essentielle à l’efficience des activités de nombreux laboratoires, centres d’essai et sites industriels. Découvrez comment optimiser l’état et la sécurité de vos systèmes de distribution de gaz, réduire vos coûts et préparer votre équipe pour réussir.