Dobladoras de Tubo Eléctricas Swagelok®

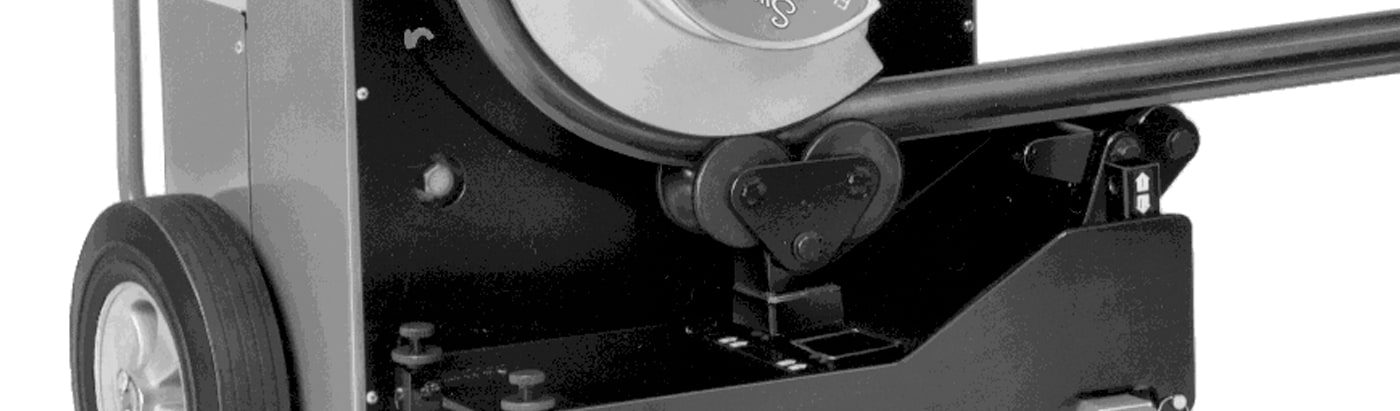

Disfrute del control preciso y la eficiencia de las dobladoras de tubo eléctricas Swagelok. Diseñadas para tubo de mayor diámetro, estas dobladoras de fácil uso minimizan el tiempo y el esfuerzo de instalación. También reducen el riesgo de deformación o daños en el tubo durante el proceso de doblado.

Obtenga Ayuda para Seleccionar Dobladoras de TuboLas dobladoras de tubo eléctricas Swagelok ofrecen curvas precisas y de alta calidad en tubo fraccional y métrico compatible con los racores para tubo Swagelok. Con control electrónico, estas dobladoras intuitivas mejoran la eficiencia y la consistencia en la instalación del tubo. El diseño versátil reduce la cantidad de herramientas de mano necesarias, con dos matrices de doblado que cubren una gran variedad de tamaños de tubo.

Cómo Doblar el Tubo y Cuándo es Beneficioso Hacerlo

Especificaciones

- Rango de doblado de 1 a 110°

- Para tubo de 25 a 50 mm de diámetro exterior (1,2 a 5,0 mm de espesor de pared) y de 1 a 2 pulg. de diámetro exterior (0,049 a 0,220 pulg. de espesor de pared)

- Una sola matriz para tubo de 1, 1 1/4, 1 1/2 y 2 pulg.

- Una sola matriz para tubo de 25, 32, 38 y 50 mm

| Dimensiones—Posición Vertical | 112 cm (44 pulg.) de alto, 74 cm (29 pulg.) de ancho, 76 cm (30 pulg.) de fondo |

| Peso | 191 kg (420 lbs.) |

| Requisitos de Alimentación | MS-TBE-1: 115 V (ac), 50/60 Hz; intensidad máxima—13 A MS-TBE-2: 230 V (ca) 50/60 Hz; intensidad máxima—7 A |

Catálogos de Dobladoras de Tubo Eléctricas

Encuentre información detallada de producto, incluidos materiales de construcción, valores nominales de presión y temperatura, opciones y accesorios.

Swagelok® tube benders provide high-quality bends on fractional and metric tubing made from materials that can be used with Swagelok tube fittings. Tube preparation tools, including tube cutters and preswaging tools, are also available.

Dobladora de Tubo para Banco Swagelok

Utilice la dobladora de tubo para banco Swagelok® para doblar de forma precisa, repetible y de alta calidad tubo de la mayoría de los materiales. Tanto si utiliza tubo de pequeño diámetro y pared delgada como tubo de gran diámetro y pared gruesa, este vídeo ofrece consejos y buenas prácticas para el doblado del tubo.

Vea la Dobladora de Tubo en FuncionamientoRecursos Swagelok Elaborados para Vd.

Essential Training in Fluid System Fundamentals

Swagelok® essentials training courses provide critical skills for developing, building, and maintaining dependable fluid systems.

Case Study: Swagelok Helps Green Alternative Systems Control Labor Costs with Tube Bending Solutions

With Swagelok’s help testing ways to control labor costs, Green Alternative Systems (GAS) experienced a 75% reduction in production time—which translated into $224,000 in annual labor savings. Read more about how the collaboration paid off.

The Three T’s to Achieve an Intricate System of Tubing

Learn how the three T’s to using a hand tube bender can help you achieve an intricate system of tubing with fewer leak points and efficient flow.

How to Use a Swagelok Hand Tube Bender

Learn how to use a hand tube bender to accurately and efficiently make 90° and 180° bends in tubing. Swagelok® hand tube benders provide consistent, high-quality bends in tubing made from most materials used with Swagelok tube fittings.