Rohrverschraubungen und Adapter von Swagelok®

Reduzieren Sie Leckagen und Ausfallzeiten durch Doppelklemmringverschraubungen, die auch nach mehrfachem Ein- und Ausbau leckagefrei abdichten, die Rohre sicher halten und vibrationsfest sind.

Rohrverschraubungen | Einfache Montage zur Freude der Monteure

Rohradapter | Vielfältige Verbindungsmöglichkeiten und Lösung schwieriger Ausrichtungsprobleme

Verschraubungen von Swagelok sind anderen Verschraubungen überlegen, wenn es darum geht, das Risiko von Leckagen und kostspieligen Ausfallzeiten in verschiedenen Branchen zu reduzieren. Das fortschrittliche Design des hinteren Klemmrings isoliert Spannungen, um Vibrationen, Biegung und Durchbiegung zu widerstehen, während ein patentiertes Aufkohlungsverfahren die Festigkeit erhöht, ohne die Korrosionsbeständigkeit zu beeinträchtigen. Rohrverschraubungen von Swagelok sind einfach zu montieren und demontieren und erfordern weniger Aufwand als Alternativen.

Rohrverschraubungen und Übergangsstücke sind in verschiedenen Legierungen erhältlich, um die chemische Beständigkeit zu gewährleisten. Für die korrekte Installation bieten wir Schulungen durch unsere Experten an. Rohradapter von Swagelok können mit allen anderen Rohrverschraubungen von Swagelok verwendet werden, so dass keine speziellen Winkel- und T-Stücke vorrätig gehalten werden müssen. Swagelok-Rohrverschraubungen aus Edelstahl, die mit Rohren aus Edelstahl 316 und 316 Ti verwendet werden, wurden gemäß den Anforderungen von ECE R110 getestet und sind auch mit EC-79-Zertifizierung erhältlich. Swagelok bietet Verschraubungen aus Werkstoffen an, die die metallurgischen Anforderungen nach NACE MR0175/ISO 15156 und MR0103 erfüllen. Darüber hinaus entsprechen die Verschraubungen aus den Legierungen 2507 und 6MO standardmäßig den Normen NORSOK M-630 und M-650.

Rohrverschraubung- und Rohradapter—Kategorien

Aufschraubverschraubungen

Verschraubungen mit Innengewinde sind in vielen Werkstoffen, Größen & Konfigurationen erhältlich und bieten leckagefreie und vibrationsbeständige Abdichtungen.

Ersatzteile und Zubehör

Entdecken Sie Ersatz- und Zubehörteile für Rohrverschraubungen – vordere & hintere Klemmringe, Muttern, Dichtungen, O-Ringe, Prüflehren, Schraubenschlüssel etc.

Gerade Einschraubverschraubungen

Verschraubungen mit Außengewinde sind in vielen Werkstoffen, Größen & Konfigurationen erhältlich und bieten leckagefreie und vibrationsbeständige Abdichtungen.

Gerade Verschraubungen

Gerade, Winkel-, T- und Kreuzverschraubungen in vielen Werkstoffen und Größen bieten eine herausragende Vibrationsbeständigkeit und Abstützung.

Muffenschweißfittings

Muffenschweißenden bieten eine korrekte Ausrichtung in Systemen mit geringem Durchmesser und sind vielen Größen und Konfigurationen erhältlich.

Reduzierstücke

Reduzierstücke in gerader und T-Ausführung sind in vielen Werkstoffen verfügbar und ermöglichen eine einfache und prüflehrenfähige Installation.

Reduzierverschraubung ohne Totvolumen

Reduzierverschraubungen ohne Totvolumen wurden entwickelt, um die Gesamteffizienz von industriellen Fluidsystemen zu steigern.

Rohradapter

Gerade Rohradapter, Winkel- und T-Stücke für einen Anschluss zwischen Swagelok®-Verbindungen und zahlreichen anderen Endanschlussarten.

Rohrstücke

Rohrstücke ermöglichen einen direkten Anschluss zwischen Verschraubungen und sind auch bei Demontage und Wiedermontage gleichbleibend prüflehrenfähig.

Schmelzsicherungs-Rohrstutzen

Schmelzsicherungs-Rohrstutzen erhöhen die Sicherheit von industriellen Fluidsystemen, indem sie bei bestimmten Temperaturen Druck in die Atmosphäre ablassen.

Schmutzfänger

Schmutzfänger (Entlüftungsschutz) sind mit einem Drahtgitter versehen, damit Insekten und andere Fremdkörper nicht in die Systeme gelangen und Schäden verursachen.

Schottverschraubungen

Schottverschraubungen und -adapter sind in vielen Größen und mit vielen Anschlüssen erhältlich und dienen zur Verbindung von Komponenten durch Trennplatten etc.

Verbindungen mit geringem Totvolumen

Verbindungen mit geringem Totvolumen von Swagelok® steigern die Effizienz von Fluidsystemen – selbst bei den anspruchsvollsten Umgebungsbedingungen.

Verschlusskappen und Stopfen

Verschlusskappen und -stopfen sind in vielen Werkstoffen und Größen verfügbar und bieten eine leckagefreie Abdichtung sowie höhere Systemsicherheit.

Rohrverschraubungen und Adapter—Kataloge

Die Rohrverschraubungen und Rohradapter von Swagelok sind in Rohrgrößen von 1/16 bis 2 Zoll bzw. 2 bis 50 mm und in verschiedenen Konfigurationen erhältlich. Die Vielzahl an Werkstoffen ermöglicht eine hervorragende Korrosionsbeständigkeit in unterschiedlichsten Anwendungsbereichen, einschließlich der chemischen Verarbeitung und Sauergasanwendungen. In der hier bereitgestellten Produktliteratur finden Sie ausführliche Produktinformationen zu Werkstoffen, Drücken, Temperaturen, Werkzeugen und Zubehör sowie zur Installation.

The proven Swagelok® tube fitting design manufactured from corrosion-resistant alloy 2507 with NORSOK M0630 and M-650 compliance standard, NACE MR0175/ISO 15156 optional.

Ventilblöcke und modulare Systeme zur Montage an Instrumenten, Direktmontage und Montage vor Ort; Ventilblöcke der Serien V, VB und VL mit 2, 3 und 5 Ventilen; Direktmontage-Ventilblöcke der Serie VE mit 2, 3 und 5 Ventilen; Ventilblöcke zur Montage vor Ort mit 2 Ventilen; Modulare Instrumentierungssysteme Mod 85

Temperaturbereich von -20 bis 204°C (-70 bis 400°F); Arbeitsdruck bis 18,9 bar (275 psig).; Größen von 1/8 bis 1/2 Zoll

Geeignet für Flüssigkeits- oder Gas-Chromatografie; Konstruktion aus Edelstahl 316; Erhältlich in Größen von 1/16 bis 1/2 Zoll

Edelstahlkonstruktion, O-Ring aus Fluorkautschuk FPM; Verlässliche, wiederholbare Abdichtung; Erhältlich für Rohrgrößen von 1/16 bis 1 1/2 Zoll

Erhältlich in Rohrgrößen von 2 bis 50 mm und 1/16 bis 2 Zoll; Gleichbleibende Prüflehrenfähigkeit nach Erstmontage; Einfache Wiedermontage; Große Auswahl an Werkstoffen und Ausführungen

Abmessungen von 1/16 bis 1 Zoll; Edelstahl 316, Messing und C-Stahl; NPT-, ISO/BSP- und SAE-Gewinde

Erfahren Sie mehr über unsere Rohrverschraubungen für mittleren und hohen Druck

Sind Sie auf der Suche nach Verschraubungen, die für Drücke von über 11.000 psi geeignet sind? Informieren Sie sich über unsere Rohrverschraubungen der Serie FK für mittleren Druck, die für Anwendungen bis zu 22.500 psi (1.551 bar) ausgelegt sind, sowie über unsere Konus-/Gewindeverschraubungen, die für Anwendungen bis zu 60.000 psi (4.134 bar) ausgelegt sind.

Ihre Auswahl an höheren DruckstufenSwagelok-Ressourcen für Sie zusammengestellt

Verschraubungen—eine Einleitung: Ermittlung der Größe und Steigung von Gewinden

Selbst erfahrene Experten haben manchmal Schwierigkeiten damit, Gewinde eindeutig zu bestimmen. Erfahren Sie von Andy Hitchcock, Product Manager bei Swagelok, wie Sie die Gewindegröße und -steigung Ihrer Verschraubungen mithilfe von Messschieber, Gewindeschablone und Gewindeidentifikationshilfe ermitteln.

Holen Sie mit Klemmringverschraubungen mehr aus Ihren Öl- und Gasanlagen heraus

Informieren Sie sich über unsere Klemmringverschraubungen für Offshore-Öl- und Gasanlagen mit mittlerem Druck und welche Vorteile diese gegenüber Konus-/Gewindeverschraubungen im Hinblick auf Installationszeiten und Leistung bieten.

Wie die Shenyang Blower Works Group von sicheren und zuverlässigeren Prozessen profitiert

Erfahren Sie in diesem Beitrag, wie Swagelok Shanghai der Shenyang Blower Works Group Corporation dabei geholfen hat, gleichbleibend hochwertige, zuverlässige und kosteneffiziente Lösungen für Kunden zu entwickeln und dabei gleichzeitig die eigene Sicherheit und Produktionseffizienz zu optimieren.

Wie Sie mit den Rohradaptern von Swagelok Ausrichtungsprobleme einfach umgehen können

Mit Rohradaptern können schwierige Ausrichtungspositionen gelöst und gleichzeitig Lagerbestände verringert werden. In diesem Video erfahren Sie, wie Sie mit den Rohradaptern von Swagelok® für eine leckagefreie Abdichtung ohne Ausrichtungsprobleme sorgen.

Seit 1947 ist Swagelok führend in der Entwicklung von Rohrverschraubungstechnologie, die in industriellen Fluidsystemanwendungen in nahezu jeder Branche eingesetzt wird.

Der Gründer von Swagelok über seine revolutionäre Rohrverschraubung

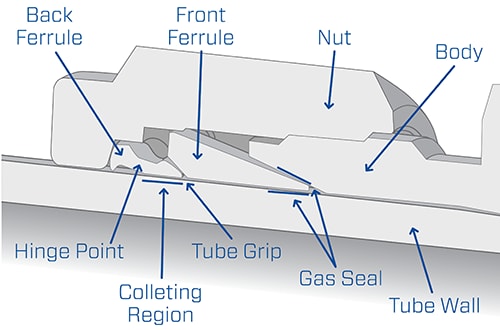

Über 75 Jahre später ist die Rohrverschraubung von Swagelok mit ihrem einzigartigen Scharnier-Spann-Effekt nach wie vor ein zuverlässiger Garant für einen dauerhaften und leckagefreien Systembetrieb. Der Kraftschluss wird über den Scharnier-Spann-Effekt erzielt, um in vier Schlüsselbereichen für optimale Leistung zu sorgen:

Rohrklemmung

Durch den Scharnier-Spann-Effekt wird der Rohrkontakt / die Rohrklemmung für besseren Halt verstärkt.

Gasdichtigkeit

Der Schleif-/Poliervorgang des vorderen Klemmrings sorgt für konzentrierte Kontaktzonen auf dem Rohr und der Körperschräge für eine solidere Abdichtung.

Vibrationsfestigkeit

Der Spannbereich isoliert Belastungskerben bei der Rohrerfassung besser und sorgt damit für einen erhöhten Widerstand gegen Biegungen, Ablenkungen und Vibrationen.

Auslegung der Rohrverschraubungen von Swagelok®

Die fortschrittliche Geometrie mit Scharnier-Spann-Effekt am hinteren Klemmring ist Standard bei allen 1/4 bis 1 Zoll und 6 bis 25 mm Swagelok-Rohrverschraubungen aus Edelstahl, um Monteuren bei der Herstellung konsistenter, leckagefreier Rohrverbindungen zu helfen. In diesen Größen tragen das patentierte Einsatzhärteverfahren und die speziell konstruierte Geometrie zum einzigartigen technischen Vorteil des hinteren Klemmrings von Swagelok bei. Durch die Geometrie des hinteren Klemmrings kommt es zu einem verbesserten Scharnier-Spann-Effekt.