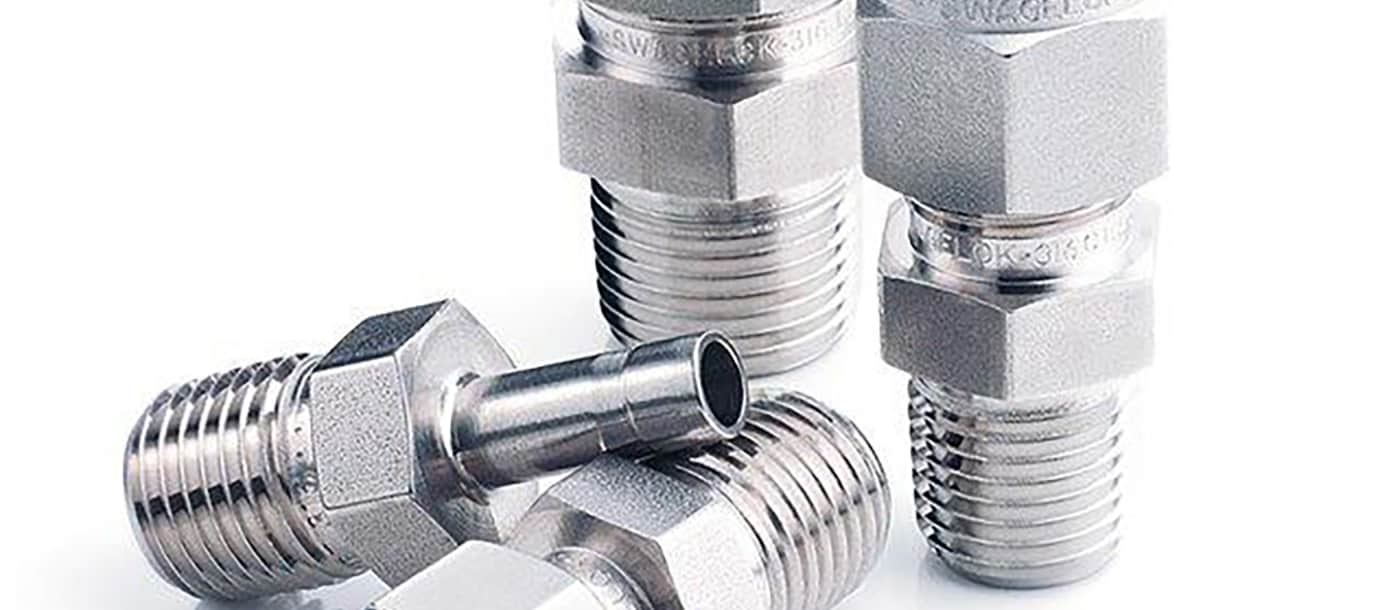

Accesorios Abocardados con Rosca de Paso Fino de PFA de Alta Pureza

Los accesorios abocardados Swagelok® con rosca de paso fino de PFA ofrecen una operación segura y eficiente de los sistemas de fluidos en aplicaciones de ultra alta pureza. Son ideales para utilizar en la producción de semiconductores y en entornos químicos agresivos.

Obtenga Ayuda para Seleccionar Accesorios Abocardados de PFALos accesorios Swagelok® abocardados con rosca de paso fino de PFA están fabricados con fluoropolímero moldeado. Estos accesorios tienen alta resistencia a la tracción, resistencia a la permeación, estabilidad térmica y mantienen conexiones estancas en sistemas de fluidos exigentes. Los accesorios Swagelok de PFA son compatibles con otros productos de ultra alta pureza, incluyendo las válvulas y el tubo, para crear sistemas totalmente integrados y adecuados para manipular fluidos agresivos. Los accesorios están disponibles en distintos tamaños y formas, como configuraciones rectas, en codo y en te. Para adaptarse a las necesidades de las aplicaciones, están disponibles con cuerpos estándar de PFA y tuercas de PVDF, o configuraciones totalmente de PFA y totalmente de PVDF.

Maximice su Sistema de Fluidos

Especificaciones

| Presión de Servicio | Hasta 18,9 bar (275 psig). |

| Temperatura de Servicio | 23 a 176°C (75 a 350°F) |

| Cuerpo | PFA de Alta Pureza |

| Tuercas | PVDF (estándar), PFA (opcional) |

| Conexión Final | Tamaños: 1/8 a 1 pulg. Configuraciones: Rectos, codos, tes, tapones para tubo, tapones para racor, tuercas, accesorios de PVDF. |

Catálogos de Accesorios Abocardados con Rosca de Paso Fino de PFA de Alta Pureza

Encuentre información detallada de producto, incluidos materiales de construcción, valores nominales de presión y temperatura, las opciones y los accesorios.

Features: Available in 1/4, 3/8, 1/2, 3/4 and 1 in. tube sizes; PFA and PVDF nut options; A wide variety of configurations

Introducción a los Racores: Identificación del Tamaño y Paso de la Rosca

Hasta para los profesionales más experimentados puede ser difícil identificar roscas. El director de producto Andy Hitchcock describe cómo identificar el tamaño y paso de las roscas de los racores con un calibre, una galga para roscas y la guía de identificación de roscas.

Más sobre la Selección de AccesoriosRecursos Swagelok Elaborados para Vd.

Soluciones Fiables de Sistemas de Fluidos para la Frontera Científica

Vea por qué el fabricante finlandés de refrigeradores de dilución Bluefors, confía en Swagelok para los componentes y soluciones de sistemas de fluidos que ayudan a hacer posible, entre otras, la informática cuántica o la física experimental.

Construir Plantas de Semiconductores más Rentables

Vea por qué la elección de piezas y conjuntos de sistemas de fluidos de alta calidad, puede contribuir a acelerar la construcción de instalaciones de fabricación de semiconductores y a reducir el coste total de propiedad durante la vida útil de la instalación.

Mejorar el Rendimiento de los Semiconductores con Aleaciones Optimizadas

Vea cómo los fabricantes de semiconductores pueden mejorar el rendimiento de la producción de extremo a extremo, y mejorar la rentabilidad a largo plazo mediante la selección de los metales adecuados para los componentes críticos de los sistemas de fluidos.

P&R: Pasado, Presente y Futuro de la Fabricación de Semiconductores

Vea cómo la colaboración entre los fabricantes de herramientas, los fabricantes de microchips y los proveedores de soluciones para sistemas de fluidos ha permitido que el mercado del semiconductor se mantenga a la altura de las exigencias de la Ley de Moore durante décadas, y hacia dónde nos dirigimos a partir de aquí.