Swagelok®-Verschraubungen

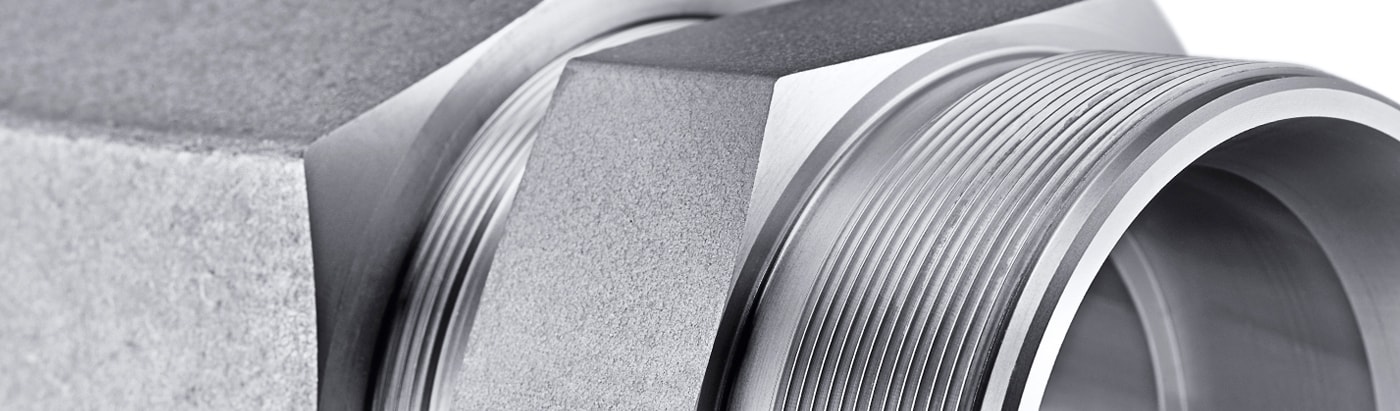

Verschraubungen von Swagelok bieten Betreibern von industriellen Fluidsystemen die Zuverlässigkeit, Montagefreundlichkeit und Dichtheit, die für den sicheren und effizienten Betrieb von Prozessen und Anlagen erforderlich sind.

Alle Verschraubungen anzeigenSeit der Einführung der Swagelok®-Rohrverschraubung im Jahr 1947 verlassen sich Branchenexperten auf Verschraubungen von Swagelok, um leckagefreie Verbindungen in ihren Analyse-, Instrumentierungs- und Prozessfluidsystemen mit kleinen Nennweiten herzustellen. Ganz gleich, ob Sie Verschraubungen für korrosive Umgebungen, extreme Temperaturen oder hohe Drücke benötigen—wir bieten Ihnen zuverlässige Lösungen für zuverlässige Verbindungen. Unsere Produktpalette umfasst ein umfangreiches Angebot an Verschraubungen in einer Vielzahl von Legierungen für ein breites Spektrum industrieller Anwendungen, einschließlich solcher mit besonderen Anforderungen.

Dank streng kontrollierter Fertigungsprozesse erfüllen die Verschraubungen von Swagelok hohe Qualitätsstandards, so dass Anwender diese vielseitigen, leistungsstarken Verschraubungen ohne Bedenken in die Auslegung ihrer Fluidsysteme integrieren können. Wenn Sie technische Unterstützung oder Schulungen benötigen, um diese Produkte in Ihren Systemen optimal zu nutzen, stehen Ihnen fast 200 autorisierte Swagelok Vertriebs- und Servicezentren weltweit zur Verfügung.

Sie benötigen Beratung bei der Auswahl und Montage unserer Verschraubungen?

Категории фитингов

PFA 가는 나사(Fine Thread) 확관형 피팅

PFA 피팅은 반도체 생산과 같은 고순도 애플리케이션을 운영하는 데 필요한 인장 강도, 열 안정성, 크리프(Creep) 내성을 제공합니다.

Verschraubungen—Kataloge

Hier finden Sie ausführliche Produktinformationen zu Werkstoffen, Drücken und Temperaturen, Optionen und Zubehör.

The proven Swagelok® tube fitting design manufactured from corrosion-resistant alloy 2507 with NORSOK M0630 and M-650 compliance standard, NACE MR0175/ISO 15156 optional.

Features: Available in 1/4, 3/8, 1/2, 3/4 and 1 in. tube sizes; PFA and PVDF nut options; A wide variety of configurations

Manifolds para instrumentación, de montaje directo y remoto, y Sistemas modulares; Manifolds para instrumentación series V, VB y VL de 2, 3 y 5 válvulas; Manifolds de montaje directo serie VE de 2, 3 y 5 válvulas; Manifolds de montaje remoto de 2 válvulas; Sistemas modulares de instrumentación Mod 85

FK and IPT Series Products Cone and thread or medium-pressure tube fitting connections Excellent corrosion resistance in chloride-containing environmentsManufactured to meet NORSOK and NACE® MR0175/ISO15156

Tamaños de 6 a 18 mm y de 1/8 a 1 pulg; Materiales: aceros inoxidables 316, 316L, 316L VAR y 316L VIM-VAR; Accesorios para equipos de soldadura manual o automática

Construcción en acero inoxidable, Junta tórica de FKM fluorocarbono; Cierre fiable y repetitivo; Disponibles en tamaños desde 1/16 a 1 1/2 pulg.

Los accesorios dieléctricos aíslan los instrumentos de medición de los efectos de la corriente eléctrica. Instalados en las líneas de impulso antes de las estaciones de medición de las tuberías de gas natural, interrumpen la corriente catódica sin restringir el caudal.El diseño de estos accesorios es único, en el sentido de que separan las dos funciones principales de aislamiento eléctrico y contención del fluido. Los aisladores termoplásticos tienen una gran resistencia dieléctrica sobre un amplio rango de condiciones operativas y climáticas. El cierre principal del accesorio lo produce una junta quad seal de FKM fluorocarbono.

Características: Transición sin rosca y sin soldaduras de sistemas de tubería con bridas a sistemas de tubo; Los tipos de bridas cumplen las normas ASME, DIN, EN y JIS; Cuerpo forjado de una pieza mecanizado integralmente; Disponible con conexiones finales mediante racores para tubo Swagelok® de hasta 50 mm y 2 pulg.

Disponibles en medidas de tubo desde 2 a 50 mm y desde 1/16 a 2 pulg.; Galgabilidad consistente en la instalación inicial; Fácil desconexión y reutilización; Gran variedad de materiales y configuraciones

Tamaños de 1/16 a 1 pulgada; Acero inoxidable 316, latón y acero al carbono; NPT, ISO/BSP y SAE

Tamaños de 6 a 18 mm y de 1/16 a 1 pulg.; Aceros inoxidables de alta pureza; La auténtica marca y el diseño original VCR

Características: Construcción en acero inoxidable 316; Temperaturas hasta 537°C (1000°F); Tamaños de los accesorios de media presión (MP)—1/4 a 1 pulg., Presión de servicio—hasta 1378 bar (20.000 psig); Tamaños de los accesorios de alta presión (HP)—1/4 a 9/16 pulg., Presión de servicio—hasta 4134 bar (60.000 psig); Disponibles en cumplimiento de NACE® MR0175/ISO15156

Temperaturas de servicio desde 20 a 204°C (70 a 400ºF); Presiones de servicio hasta 18,9 bar (275 psig); Tamaños desde 1/8 a 1/2 pulg.

Features: Suitable for liquid or gas chromatography; 316 stainless steel construction; Offered in sizes from 1/16 to 1/2 in.

Esferas de tamaños de 40, 50, 63, 100, 115, y 160 mm (1 1/2, 2, 2 1/2, 4, 4 1/2 y 6 pulg.) Precisión según ASME, EN y JIS; Disponibles con variedad de conexiones finales, incluyendo adaptadores a tubo Swagelok®; Configuraciones de montaje posterior central, posterior inferior e inferior; Construcción en acero inoxidable y material termoplástico reforzado; Disponibles sin rellenar o rellenos de líquido

Tamaños de 1/8 a 1 pulg.; Acero inoxidable 316 ó 316L ; Conexiones a tubo, NPT, SAE y para soldar

Vorteile der Rohrverschraubungen von Swagelok®

Die Rohrverschraubungen von Swagelok erfüllen dank ihrer bewährten Auslegung, der präzisen Herstellung und hochwertiger Werkstoffe selbst die höchsten Anforderungen in Sachen Sicherheit und Zuverlässigkeit.

Entdecken Sie die VorteileSwagelok-Ressourcen für Sie zusammengestellt

Verschraubungen—eine Einleitung: Ermittlung der Größe und Steigung von Gewinden

Selbst erfahrene Experten haben manchmal Schwierigkeiten damit, Gewinde eindeutig zu bestimmen. Erfahren Sie von Andy Hitchcock, Product Manager bei Swagelok, wie Sie die Gewindegröße und -steigung Ihrer Verschraubungen mithilfe von Messschieber, Gewindeschablone und Gewindeidentifikationshilfe ermitteln.

Wie die Shenyang Blower Works Group von sicheren und zuverlässigeren Prozessen profitiert

Erfahren Sie in diesem Beitrag, wie Swagelok Shanghai der Shenyang Blower Works Group Corporation dabei geholfen hat, gleichbleibend hochwertige, zuverlässige und kosteneffiziente Lösungen für Kunden zu entwickeln und dabei gleichzeitig die eigene Sicherheit und Produktionseffizienz zu optimieren.

Installation von Swagelok-Rohrverschraubungen

In diesem Video zeigen wir die wichtigsten Schritte bei der Installation von Swagelok-Rohrverschraubungen, die sich in zahlreichen Anwendungen weltweit durch ihre Leistung, Qualität und Zuverlässigkeit bewährt haben.

Swagelok-Verschraubungen

Wenn weltweit renommierte Unternehmen dauerhafte Verbindungen suchen, wenden sie sich an Swagelok. Im Bereich Rohrverschraubungen setzen wir Maßstäbe in puncto Dichtheit, Montagefreundlichkeit, Verfügbarkeit und Kundenservice. Unsere Doppelklemmringverschraubung aus Edelstahl genießt weltweit einen guten Ruf für Beständigkeit, Qualität und Zuverlässigkeit. Dieser Ruf wird durch unsere kontinuierlichen Bemühungen zur Produktverbesserung und durch den bewährten Einsatz der Verschraubung in Tausenden von verschiedenen Anwendungen bestätigt.