Rohrverschraubungen und Adapter von Swagelok®

Reduzieren Sie Leckagen und Ausfallzeiten durch Doppelklemmringverschraubungen, die auch nach mehrfachem Ein- und Ausbau leckagefrei abdichten, die Rohre sicher halten und vibrationsfest sind.

Rohrverschraubungen | Einfache Montage zur Freude der Monteure

Rohradapter | Vielfältige Verbindungsmöglichkeiten und Lösung schwieriger Ausrichtungsprobleme

Verschraubungen von Swagelok sind anderen Verschraubungen überlegen, wenn es darum geht, das Risiko von Leckagen und kostspieligen Ausfallzeiten in verschiedenen Branchen zu reduzieren. Das fortschrittliche Design des hinteren Klemmrings isoliert Spannungen, um Vibrationen, Biegung und Durchbiegung zu widerstehen, während ein patentiertes Aufkohlungsverfahren die Festigkeit erhöht, ohne die Korrosionsbeständigkeit zu beeinträchtigen. Rohrverschraubungen von Swagelok sind einfach zu montieren und demontieren und erfordern weniger Aufwand als Alternativen.

Rohrverschraubungen und Übergangsstücke sind in verschiedenen Legierungen erhältlich, um die chemische Beständigkeit zu gewährleisten. Für die korrekte Installation bieten wir Schulungen durch unsere Experten an. Rohradapter von Swagelok können mit allen anderen Rohrverschraubungen von Swagelok verwendet werden, so dass keine speziellen Winkel- und T-Stücke vorrätig gehalten werden müssen. Swagelok-Rohrverschraubungen aus Edelstahl, die mit Rohren aus Edelstahl 316 und 316 Ti verwendet werden, wurden gemäß den Anforderungen von ECE R110 getestet und sind auch mit EC-79-Zertifizierung erhältlich. Swagelok bietet Verschraubungen aus Werkstoffen an, die die metallurgischen Anforderungen nach NACE MR0175/ISO 15156 und MR0103 erfüllen. Darüber hinaus entsprechen die Verschraubungen aus den Legierungen 2507 und 6MO standardmäßig den Normen NORSOK M-630 und M-650.

Tube Fitting and Tube Adapter Categories

Bulkheads

Bulkhead tube fittings and adapters are designed to help make a connection between two sides of a partion and are available in a range of sizes and connections for your application.

Caps and Plugs

Tube fitting caps and plugs are available in a range of materials and sizes to enable leak-tight sealing and enhanced system safety in a range of applications.

Female Connectors

Female connector tube fittings, available in a range of materials, sizes and configurations, deliver a leak-tight seal that is resistant to vibration fatigue.

Fusible Tube Adapters

Fusible tube adapter fittings enhance the overall safety of your industrial fluid system by releasing pressure to atmosphere at a given temperature.

Low Dead Volume Unions

Swagelok low dead volume tube fittings are engineered to reliably increase the overall efficiency of your industrial fluid system, even in harsh environments.

Male Connectors

Male connector tube fittings, available in a range of materials, sizes and configurations, deliver a leak-tight seal that is resistant to vibration fatigue.

Mud Daubers

Browse mud dauber fittings (vent protectors) designed with a mesh wire screen to prevent insects and other foreign objects from clogging or damaging systems.

Port Connectors

Swagelok port connectors enable fitting-to-fitting connections, offer consistent gaugeability upon installation, and are easy to disconnect and retighten.

Reducers

Tube fitting reducing straights and tees are available in a variety of materials and provide easy installation and consistent gaugeability.

Socket Weld Fittings

Socket weld tube fittings enable proper alignment in small bore fluid systems. Available in multiple sizes and configurations to fit your application.

Spare Parts and Accessories

Explore tube fitting replacement parts and accessories—front ferrules, back ferrules, nuts, gaskets, o-rings, gap inspection gauges, wrenches—and more.

Tube Adapters

Tube adapter straights, elbows and tees allow for fitting-to-fitting connections between a Swagelok tube fitting and a variety of other end connection types.

Unions

Tube fitting union straights, elbows, tees, and crosses in a variety of materials and sizes provide excellent vibration fatigue resistance and tube support.

Zero Volume Reducers

Browse zero volume tube fitting reducers engineered to reliably increase the overall efficiency of your industrial fluid system.

Rohrverschraubungen und Adapter—Kataloge

Die Rohrverschraubungen und Rohradapter von Swagelok sind in Rohrgrößen von 1/16 bis 2 Zoll bzw. 2 bis 50 mm und in verschiedenen Konfigurationen erhältlich. Die Vielzahl an Werkstoffen ermöglicht eine hervorragende Korrosionsbeständigkeit in unterschiedlichsten Anwendungsbereichen, einschließlich der chemischen Verarbeitung und Sauergasanwendungen. In der hier bereitgestellten Produktliteratur finden Sie ausführliche Produktinformationen zu Werkstoffen, Drücken, Temperaturen, Werkzeugen und Zubehör sowie zur Installation.

The proven Swagelok® tube fitting design manufactured from corrosion-resistant alloy 2507 with NORSOK M0630 and M-650 compliance standard, NACE MR0175/ISO 15156 optional.

V, VB, and VL series 2-, 3-, and 5-valve instrument manifolds; VE series 2-, 3-, and 5-valve direct-mount manifolds; 2-valve remote-mount manifolds; Mod 85 modular instrumentation systems

Features: Temperatures from 70 to 400°F (20 to 204°C); Working pressures up to 275 psig (18.9 bar); Sizes from 1/8 to 1/2 in.

Features: Suitable for liquid or gas chromatography; 316 stainless steel construction; Offered in sizes from 1/16 to 1/2 in.

Features: Stainless steel construction, fluorocarbon FKM O-ring; Reliable, repeatable sealing performance; Available in tube sizes from 1/16 to 1 1/2 in.

Swagelok® tube fittings and tube adapters reduce the risk of costly system downtime with reliable tubing connections and are available in a variety of sizes and materials.

Optimize sealing and minimize galling with pipe fittings manufactured to Swagelok's high quality standards in configurations such as pipe adapters and couplings.

Erfahren Sie mehr über unsere Rohrverschraubungen für mittleren und hohen Druck

Sind Sie auf der Suche nach Verschraubungen, die für Drücke von über 11.000 psi geeignet sind? Informieren Sie sich über unsere Rohrverschraubungen der Serie FK für mittleren Druck, die für Anwendungen bis zu 22.500 psi (1.551 bar) ausgelegt sind, sowie über unsere Konus-/Gewindeverschraubungen, die für Anwendungen bis zu 60.000 psi (4.134 bar) ausgelegt sind.

Ihre Auswahl an höheren DruckstufenSwagelok-Ressourcen für Sie zusammengestellt

Verschraubungen—eine Einleitung: Ermittlung der Größe und Steigung von Gewinden

Selbst erfahrene Experten haben manchmal Schwierigkeiten damit, Gewinde eindeutig zu bestimmen. Erfahren Sie von Andy Hitchcock, Product Manager bei Swagelok, wie Sie die Gewindegröße und -steigung Ihrer Verschraubungen mithilfe von Messschieber, Gewindeschablone und Gewindeidentifikationshilfe ermitteln.

Holen Sie mit Klemmringverschraubungen mehr aus Ihren Öl- und Gasanlagen heraus

Informieren Sie sich über unsere Klemmringverschraubungen für Offshore-Öl- und Gasanlagen mit mittlerem Druck und welche Vorteile diese gegenüber Konus-/Gewindeverschraubungen im Hinblick auf Installationszeiten und Leistung bieten.

Wie die Shenyang Blower Works Group von sicheren und zuverlässigeren Prozessen profitiert

Erfahren Sie in diesem Beitrag, wie Swagelok Shanghai der Shenyang Blower Works Group Corporation dabei geholfen hat, gleichbleibend hochwertige, zuverlässige und kosteneffiziente Lösungen für Kunden zu entwickeln und dabei gleichzeitig die eigene Sicherheit und Produktionseffizienz zu optimieren.

Wie Sie mit den Rohradaptern von Swagelok Ausrichtungsprobleme einfach umgehen können

Mit Rohradaptern können schwierige Ausrichtungspositionen gelöst und gleichzeitig Lagerbestände verringert werden. In diesem Video erfahren Sie, wie Sie mit den Rohradaptern von Swagelok® für eine leckagefreie Abdichtung ohne Ausrichtungsprobleme sorgen.

Seit 1947 ist Swagelok führend in der Entwicklung von Rohrverschraubungstechnologie, die in industriellen Fluidsystemanwendungen in nahezu jeder Branche eingesetzt wird.

Der Gründer von Swagelok über seine revolutionäre Rohrverschraubung

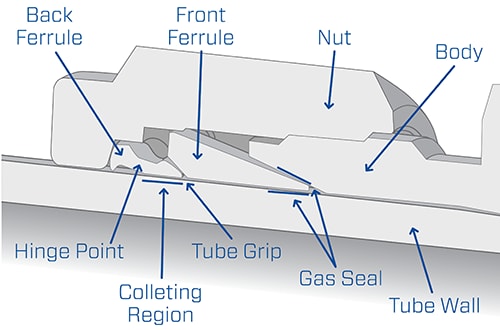

Über 75 Jahre später ist die Rohrverschraubung von Swagelok mit ihrem einzigartigen Scharnier-Spann-Effekt nach wie vor ein zuverlässiger Garant für einen dauerhaften und leckagefreien Systembetrieb. Der Kraftschluss wird über den Scharnier-Spann-Effekt erzielt, um in vier Schlüsselbereichen für optimale Leistung zu sorgen:

Rohrklemmung

Durch den Scharnier-Spann-Effekt wird der Rohrkontakt / die Rohrklemmung für besseren Halt verstärkt.

Gasdichtigkeit

Der Schleif-/Poliervorgang des vorderen Klemmrings sorgt für konzentrierte Kontaktzonen auf dem Rohr und der Körperschräge für eine solidere Abdichtung.

Vibrationsfestigkeit

Der Spannbereich isoliert Belastungskerben bei der Rohrerfassung besser und sorgt damit für einen erhöhten Widerstand gegen Biegungen, Ablenkungen und Vibrationen.

Auslegung der Rohrverschraubungen von Swagelok®

Die fortschrittliche Geometrie mit Scharnier-Spann-Effekt am hinteren Klemmring ist Standard bei allen 1/4 bis 1 Zoll und 6 bis 25 mm Swagelok-Rohrverschraubungen aus Edelstahl, um Monteuren bei der Herstellung konsistenter, leckagefreier Rohrverbindungen zu helfen. In diesen Größen tragen das patentierte Einsatzhärteverfahren und die speziell konstruierte Geometrie zum einzigartigen technischen Vorteil des hinteren Klemmrings von Swagelok bei. Durch die Geometrie des hinteren Klemmrings kommt es zu einem verbesserten Scharnier-Spann-Effekt.