Swagelok® Lubricants

Swagelok Goop™ thread lubricant reduces installation time by easing the assembly of leak-tight threaded connections for a variety of metals and alloys.

View LubricantsOur wide selection of Swagelok Goop™ thread lubricants makes assembling leak-tight connections quicker and easier. Swagelok Goop is available in oil, halocarbon, and fluourosilicone-based varieties. They are rated for use with a variety of materials and in a variety of applications, including vacuum systems.

- Silver Goop is oil-based thread lubricant for use on stainless steel and high-temperature alloys. It prevents galling, contains a non-melting antiseize agent, lowers torque on threaded parts, and stays in place between mating surfaces.

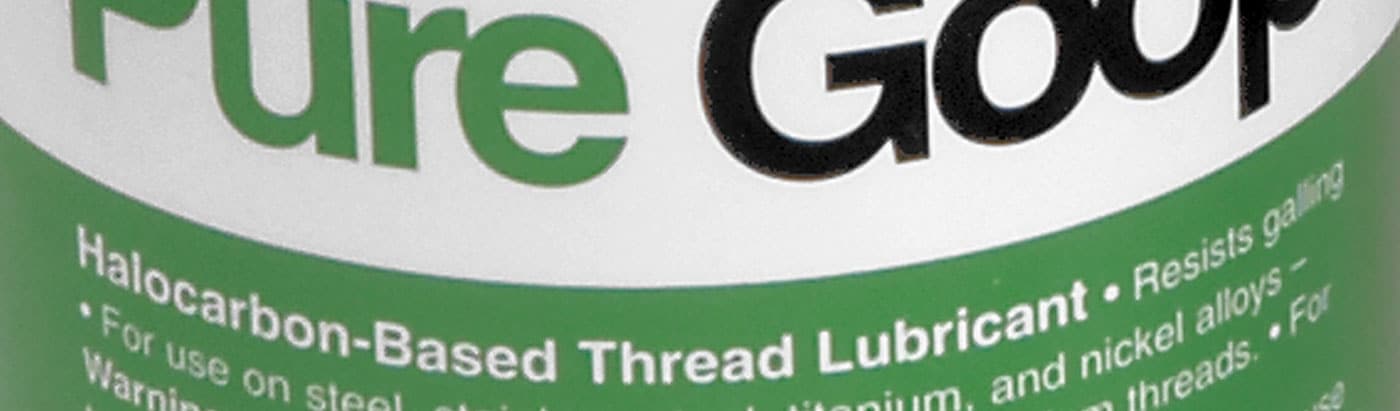

- Pure Goop is halocarbon-based thread lubricant for use on titanium, stainless steel, steel, and nickel-based alloys. It resists galling and moisture and is chemically nonreactive with a wide range of materials.

- Blue Goop is oil-based thread lubricant for use on stainless steel, titanium, aluminum, and nickel-based alloys. It resists galling and water washout and its deep blue color is unaffected by water.

- Vac Goop is fluorosilicone-based thread lubricant for use on threads, O-rings, gaskets, glass seals, and metal parts in vacuum systems. It resists galling, has extremely low vapor pressure, minimizes outgassing problems, and is chemically nonreactive with a wide range of materials.

Have questions about thread lubricants?

Категории смазок

Смазки для резьбы

Резьбовые смазки, облегчающих сборку герметичных соединений из различных металлов и сплавов.

Lubricants Catalogs

Locate detailed product information, including materials of construction, pressure and temperature ratings, options, and accessories.

Жидкие течеискатели Snoop®; Смазки для резьбы Goop™ ; Герметики для трубной резьбы SWAK®, тефлоновая лента и герметики для трубной резьбы без содержания PTFE

圧縮ガス漏れ検出サービス

圧縮ガスの漏れを特定して数値化することで、排出物の削減、安全性、コスト、生産性の向上などに基づいて、重要な問題から優先して取り組むことができます。

漏れ検出サービスの詳細を見る関連資料/コラム記事

漏れ検出の導入事例

スウェージロックの流体システム専門スタッフは、技術的およびアプリケーションに関する豊富な知識を持っており、流体システムにおける漏れを検出、排除、防止するサポートを定期的に行っています。お客さまが得たメリットを紹介します。

Common Causes and Costs of Fluid System Leaks

The smallest leak can present a serious issue when maintaining your plant’s safety and profitability. Understand how and why leaks occur, how to locate and test for them, and ultimately how to develop a strategy to address and reduce leaks plant-wide.

Combating Common Fluid System Leaks in Tire Facilities

Tire manufacturers can grow accustomed to leaking process pipes, but system leaks can pose significant safety hazards and drain profitability. Learn how to identify common leak sources throughout a plant and how to fix them.

How to Avoid System Leaks: The Importance of Proper Tube Preparation

A successful tube fitting installation depends on many criteria, but one of the most important is proper tube preparation before installation. Learn to avoid costly or dangerous leaks by avoiding damaged, burred, or improperly cut tubes.