Фитинги Swagelok®

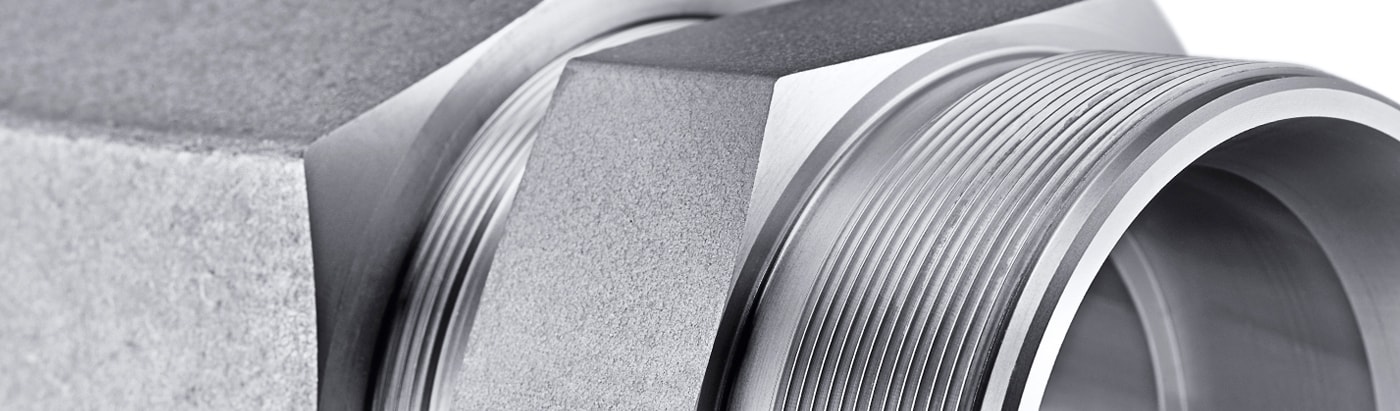

Фитинги Swagelok обеспечивают операторам промышленных газовых и жидкостных систем надежность, простоту монтажа и герметичное уплотнение, что необходимо для безопасной и эффективной работы технологических процессов и оборудования.

Показать все фитингиС момента появления фитингов Swagelok® в 1947 году отраслевые профессионалы доверяют нашей продукции, когда необходимо обеспечить герметичность соединений в аналитических системах, контрольно-измерительных приборах и технологических системах малого диаметра. Если вам нужны фитинги для агрессивных сред, экстремальных температур или высокого давления, мы предлагаем надежные варианты, которые помогут создать соединения, на которые можно положиться. Мы предлагаем полный ассортимент фитингов из различных сплавов для широкого спектра промышленных установок, в том числе с особыми требованиями.

Фитинги Swagelok отвечают наивысшим стандартам качества, достигаемые благодаря строго контролируемым процессам. Тем самым пользователи получают уверенность в комплектации своих рабочих систем нашими универсальными высококачественными фитингами. Если вам понадобится техническая поддержка или обучение по вопросам эффективного применения наших изделий в своих системах, к вашим услугам более 200 центров продаж и сервисного обслуживания Swagelok по всему миру.

Вам нужны советы по выбору и установке фитингов?

Verschraubungen—Kategorien

VCO®-Verschraubungen mit O-Ring

- Aufschraubverschraubungen

- Ersatzteile und Zubehör

- Gerade Einschraubverschraubungen

- Gerade Verschraubungen

- Schottverschraubungen

VCR®-Verbindungen mit Metalldichtscheibe

- Aufschraubverschraubungen

- Gerade Einschraubverschraubungen

- Lange Stutzen

- Reduzierstücke

- Schottverschraubungen

Verschraubungen mit Dichtkonus und Sicherungsgewinde

Tout filtrer Verschraubungen mit Dichtkonus und SicherungsgewindeКаталоги фитингов

Получите подробные сведения о продукции, в том числе о материалах изготовления, номинальных параметрах давления и температуры, вариантах исполнения и вспомогательных принадлежностях.

The proven Swagelok® tube fitting design manufactured from corrosion-resistant alloy 2507 with NORSOK M0630 and M-650 compliance standard, NACE MR0175/ISO 15156 optional.

Features: Available in 1/4, 3/8, 1/2, 3/4 and 1 in. tube sizes; PFA and PVDF nut options; A wide variety of configurations

Manifolds et systèmes modulaires à montage direct ou distant pour instrumentation; Manifolds d’instrumentation à 2, 3 ou 5 vannes séries V, VB et VL ; Manifolds à 2, 3 ou 5 vannes pour montage direct série VE ; Manifolds à 2 vannes pour montage distant ; Systèmes d’instrumentation modulaires Mod 85

FK and IPT Series Products Cone and thread or medium-pressure tube fitting connections Excellent corrosion resistance in chloride-containing environmentsManufactured to meet NORSOK and NACE® MR0175/ISO15156

6 à 18 mm et 1/8 à 1 po.; Acier inoxydable 316, 316L, 316L VAR, et 316L VIM-VAR; Raccords pour soudure manuelle ou en automatique

Fabriqués en acier inoxydable, joint torique en élastomère fluorocarboné, Étanchéité d’une efficacité fiable et reproductible, Disponibles pour tubes aux dimensions allant de 1/16 à 1 1/2 po

Features: Metal components are machined from 316 stainless steel for use in rugged environments; Molded thermoplastic insulation with excellent electrical, chemical, and ultraviolet resistance and low water absorption maintains dielectric strength and integrity over a wide range of operating and climatic conditions; Gaugeable Swagelok® tube fitting or tapered pipe thread end connections (NPT/BSP) provide direct connection to tubing or piping system.

Caractéristiques : Transition des systèmes de tuyauterie à brides aux systèmes à tubes sans filetage ni soudure ; Différents types de brides conformes aux normes ASME, DIN, EN et JIS ; Corps forgé monobloc intégralement usiné ; Disponibles avec des raccords pour tubes Swagelok® de diamètre allant jusqu’à 50 mm ou 2 po

Disponibles pour tubes de 2 à 50 mm et de 1/16 à 2 po; Systématiquement contrôlable lors du montage initial; Facile à desserrer et à resserrer; Large gamme de matériaux et de configurations

Dimensions de 1/16 à 1 po.; Acier inoxydable 316, laiton et acier au carbone; Filetages NPT, ISO/BSP, et SAE.

Dimensions : 6 à 18 mm et 1/16 à 1 po.; Aciers inoxydables haute pureté; Le modèle original, la marque VCR authentique

■ Pressions nominales jusqu'à 4134 bar (60 000 psig)■ Dimensions des raccordements jusqu’à 1 1/2 po et 12 mm■ Produits conformes aux normes NACE® MR0175/ISO15156 disponibles

Pages 1-4. températures de 20 à 204 °C (70 à 400 °F) ; pressions de service jusqu’à 18,9 bar (275 psig) ; raccords à tube de 1/8 à 1/2 po.; tubes de 1/8 à 1 po. et de 6 à 12 mm.

Features: Suitable for liquid or gas chromatography; 316 stainless steel construction; Offered in sizes from 1/16 to 1/2 in.

Dimensions de cadran de 40, 50, 63, 100, 115, et 160 mm (1 1/2, 2, 2 1/2, 4, 4 1/2 et 6 po) ; Précision conforme aux normes ASME, EN, et JIS; Disponible avec différents raccordements d’extrémité, y compris les adaptateurs pour tubes Swagelok; Configurations pour montage arrière centré, montage arrière excentré et montage vertical; Construction en acier inoxydable et thermoplastique renforcé; Disponible avec ou sans liquide

Dimensions de 1/8 à 1 po, Acier inoxydable 316 ou 316L, Raccords pour tubes, NPT, filetage SAE et à souder

Преимущества трубных обжимных фитингов Swagelok®

Трубные обжимные фитинги Swagelok рассчитаны на самые высокие требования к безопасности и надежности, характеризуются проверенной на практике конструкцией, прецизионным изготовлением и высококачественными материалами.

Узнайте о преимуществахРесурсы Swagelok специально для вас

피팅 소개: 나사 크기 및 피치 식별

경력이 많은 전문가도 가끔 나사산을 확인하기 어려울 때가 있습니다. Swagelok 제품 매니저 Andy Hitchcock이 캘리퍼, 피치 게이지, 나사산 식별 가이드를 통해 피팅의 나사산 크기와 피치를 확인하는 방법을 설명합니다.

선양 고풍기 유한공사(Shenyang Blower Works Group)의 안전 및 신뢰성 개선 사례

선양 고풍기 유한공사(Shenyang Blower Works Group)가 안전과 생산 효율성을 개선하는 동시에, 일관성, 신뢰성, 고객 비용 절감을 실현할 수 있도록 Swagelok Shanghai가 어떻게 지원했는지 알아보십시오.

Swagelok 튜브 피팅 설치

이 비디오는 일관성, 품질, 신뢰성 측면에서 국제적인 명성을 쌓아온 Swagelok 튜브 피팅을 설치하는 필수 단계를 보여줍니다.

Swagelok 피팅

세계적으로 명성이 높은 기업들도 수명이 긴 연결이 필요할 때는 Swagelok을 찾습니다. Swagelok은 누설 없는 밀폐 무결성, 손쉬운 설치, 가용성, 지원 서비스와 관련하여 튜브 피팅 성능의 표준을 정립했습니다. Swagelok 2 페럴 스테인리스강 튜브 피팅은 일관성, 품질, 신뢰성 측면에서 세계적인 평판을 확보했습니다. 이러한 평판은 Swagelok의 지속적인 제품 개선 노력과 수천 가지 다양한 애플리케이션에서 입증된 피팅 성능으로 뒷받침됩니다.