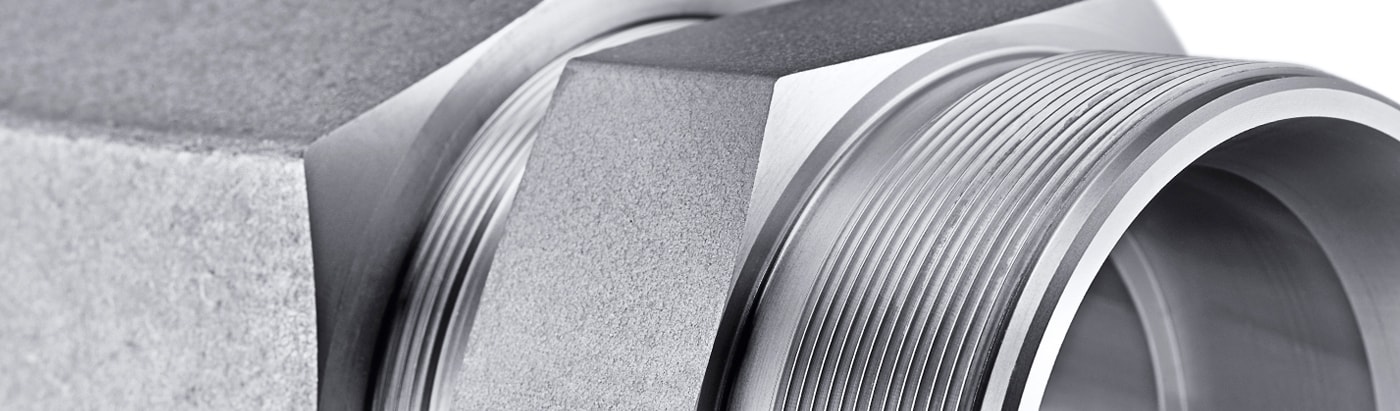

Racores Swagelok®

Los racores Swagelok ofrecen a los operadores de sistemas de fluidos industriales la fiabilidad, facilidad de instalación y estanqueidad necesarias para mantener los procesos y equipos funcionando de forma segura y eficiente.

Vea Todos los RacoresDesde la introducción del racor Swagelok® en 1947, los profesionales de la industria han confiado en los racores Swagelok para conseguir conexiones estancas en sus sistemas de fluidos analíticos, de instrumentación y para procesos de pequeño diámetro. Tanto si necesita racores para entornos corrosivos, temperaturas extremas o alta presión, le ofrecemos opciones fiables para ayudarle a crear conexiones en las que pueda confiar. Tenemos disponible una completa gama de racores en una gran variedad de aleaciones para un amplio rango de aplicaciones industriales, incluidas las más especializadas.

Los altos estándares de calidad de los racores Swagelok son posibles gracias a procesos altamente controlados, ofreciendo a los usuarios tranquilidad a la hora de integrar estos versátiles racores de alto rendimiento en los diseños de sus sistemas de fluidos. Si necesita apoyo técnico o formación para hacer el mejor uso de estos productos en sus sistemas, tiene asistencia disponible en los casi 200 centros autorizados de ventas y servicio Swagelok de todo el mundo.

¿Busca asesoramiento para seleccionar y para instalar racores?

Verschraubungen—Kategorien

Rohrverschraubungen und Adapter

- Aufschraubverschraubungen

- Ersatzteile und Zubehör

- Gerade Einschraubverschraubungen

- Gerade Verschraubungen

- Muffenschweißfittings

PFA, Feingewinde-Bördelverschraubungen

PFA-Verbindungen bieten Zugfestigkeit, thermische Stabilität und Kriechfestigkeit für den Einsatz in hochreinen Anwendungen wie der Halbleiterfertigung.

Catálogos de Racores

Encuentre información detallada de producto, incluidos materiales de construcción, valores nominales de presión y temperatura, las opciones y los accesorios.

The proven Swagelok® tube fitting design manufactured from corrosion-resistant alloy 2507 with NORSOK M0630 and M-650 compliance standard, NACE MR0175/ISO 15156 optional.

Features: Available in 1/4, 3/8, 1/2, 3/4 and 1 in. tube sizes; PFA and PVDF nut options; A wide variety of configurations

V, VB, and VL series 2-, 3-, and 5-valve instrument manifolds; VE series 2-, 3-, and 5-valve direct-mount manifolds; 2-valve remote-mount manifolds; Mod 85 modular instrumentation systems

FK and IPT Series Products Cone and thread or medium-pressure tube fitting connections Excellent corrosion resistance in chloride-containing environmentsManufactured to meet NORSOK and NACE® MR0175/ISO15156

Swagelok weld fittings provide a permanent, high-integrity connection in a variety of materials, sizes, and shapes to suit any industrial or high-purity application.

Features: Stainless steel construction, fluorocarbon FKM O-ring; Reliable, repeatable sealing performance; Available in tube sizes from 1/16 to 1 1/2 in.

Features: Metal components are machined from 316 stainless steel for use in rugged environments; Molded thermoplastic insulation with excellent electrical, chemical, and ultraviolet resistance and low water absorption maintains dielectric strength and integrity over a wide range of operating and climatic conditions; Gaugeable Swagelok® tube fitting or tapered pipe thread end connections (NPT/BSP) provide direct connection to tubing or piping system.

Features: Threadless, weldless transition from flanged piping systems to tubing systems; Flange types meet ASME, DIN, EN, and JIS standards; One-piece integrally machined forged body; Available with Swagelok® tube fitting end connections up to 50 mm and 2 in.

Swagelok® tube fittings and tube adapters reduce the risk of costly system downtime with reliable tubing connections and are available in a variety of sizes and materials.

Optimize sealing and minimize galling with pipe fittings manufactured to Swagelok's high quality standards in configurations such as pipe adapters and couplings.

Features; 1/16 to 1 in. and 6 to 18 mm sizes; High-purity stainless steels; The original design; the authentic VCR brand

Swagelok® offers medium- and high-pressure fittings, tubing, valves, and related accessories with temperatures up 1000°F (537°C), pressure ratings up to 60 000 psig (4134 bar) in sizes ranging from 1/4 to to 1 in. for medium-pressure products and 1/4 to 9/16 in. for high-pressure products. NACE® MR0175/ISO15156 compliance is available.

Features: Temperatures from 70 to 400°F (20 to 204°C); Working pressures up to 275 psig (18.9 bar); Sizes from 1/8 to 1/2 in.

Features: Suitable for liquid or gas chromatography; 316 stainless steel construction; Offered in sizes from 1/16 to 1/2 in.

Features: 40, 50, 63, 100, 115, and 160 mm (1 1/2, 2, 2 1/2, 4, 4 1/2 and 6 in.) dial sizes; Accuracy in accordance with ASME, EN, and JIS; Available with a variety of end connections, including Swagelok® tube adapters; Center-back, lower-back, and lower mount configurations; Stainless steel and reinforced thermoplastic construction; Available unfilled or liquid filled

Swagelok® VCO® O-Ring face seal fittings are designed for easy assembly in pipe, tube, and welded systems in a range of applications, even where space is limited.

La Superioridad de los Racores para Tubo Swagelok®

Los racores Swagelok están diseñados para satisfacer sus más altas expectativas de seguridad y fiabilidad, con un diseño probado, una fabricación precisa y materias primas de calidad superior.

Descubra la VentajaRecursos Swagelok Elaborados para Vd.

Introducción a los Racores: Identificación del Tamaño y Paso de la Rosca

Hasta para los profesionales más experimentados puede ser difícil identificar roscas. El director de producto Andy Hitchcock describe cómo identificar el tamaño y paso de las roscas de los racores con un calibre, una galga para roscas y la guía de identificación de roscas.

선양 고풍기 유한공사(Shenyang Blower Works Group)의 안전 및 신뢰성 개선 사례

선양 고풍기 유한공사(Shenyang Blower Works Group)가 안전과 생산 효율성을 개선하는 동시에, 일관성, 신뢰성, 고객 비용 절감을 실현할 수 있도록 Swagelok Shanghai가 어떻게 지원했는지 알아보십시오.

Swagelok 튜브 피팅 설치

이 비디오는 일관성, 품질, 신뢰성 측면에서 국제적인 명성을 쌓아온 Swagelok 튜브 피팅을 설치하는 필수 단계를 보여줍니다.

Swagelok 피팅

세계적으로 명성이 높은 기업들도 수명이 긴 연결이 필요할 때는 Swagelok을 찾습니다. Swagelok은 누설 없는 밀폐 무결성, 손쉬운 설치, 가용성, 지원 서비스와 관련하여 튜브 피팅 성능의 표준을 정립했습니다. Swagelok 2 페럴 스테인리스강 튜브 피팅은 일관성, 품질, 신뢰성 측면에서 세계적인 평판을 확보했습니다. 이러한 평판은 Swagelok의 지속적인 제품 개선 노력과 수천 가지 다양한 애플리케이션에서 입증된 피팅 성능으로 뒷받침됩니다.