Schläuche und flexible Rohre von Swagelok®

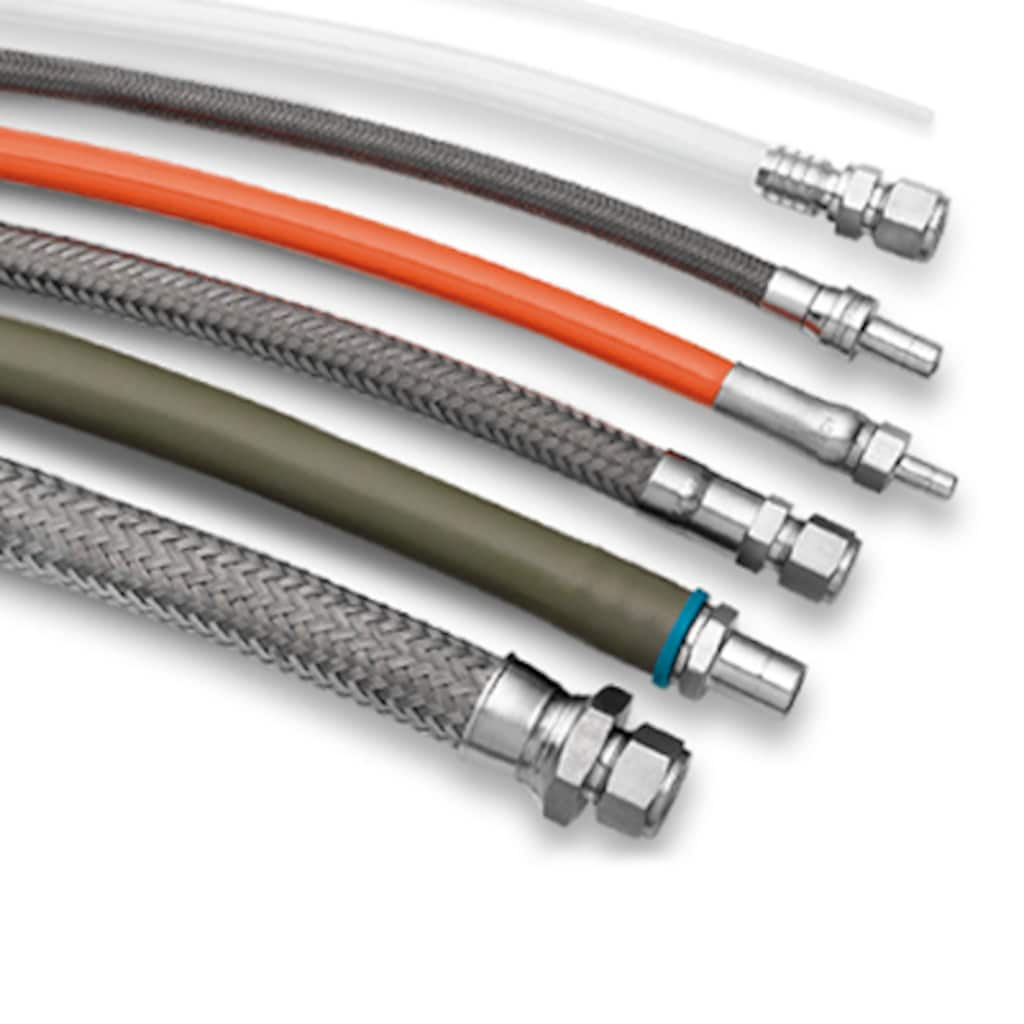

Swagelok bietet eine riesige Auswahl an gängigen industriellen Schläuchen sowie Schläuchen für hochreine Anwendungen. Wählen Sie zwischen zahlreichen Innenschlauchwerkstoffen, Verstärkungsarten, Endanschlüssen oder Isolierungsoptionen, um Ihre Anwendungsanforderungen für den Transport von Flüssigkeiten und Gasen zu erfüllen.

Schlauch | Eine mehrschichtige flexible Leitung zum Transport von Fluiden

Flexible Rohre | Eine einschichtige flexible Leitung zum Transport von Fluiden

Die breite Palette an Schlauchtypen von Swagelok ermöglicht den Bezug über einzigen Anbieter für zahlreiche Anwendungen. Alle Schläuche sind eigens von uns ausgelegt und nach den präzisen Spezifikationen von Swagelok gefertigt, um auch in extremen Anwendungsbereichen höchste Qualität zu gewährleisten. Unser Produktangebot ist auf die Druckstufen, Werkstoffe und Flexibilitätsanforderungen ausgelegt, die erforderlich sind, um die Sicherheit der Mitarbeiter sowie einen reibungslosen und wirtschaftlichen Anlagenbetrieb zu gewährleisten.

Das Angebot von Swagelok umfasst Innenschlauchwerkstoffe aus Metall, PTFE, Thermoplast und Gummi, Schlauchgrößen von 1/8 bis 2 Zoll sowie eine große Auswahl an zölligen und metrischen Endanschlüssen. Auch individuelle Ausführungen sind möglich.

Zusätzlich stehen Ihnen weltweit Swagelok-zertifizierte Schlauchexperten zur Seite, die Sie bei der Auswahl der passenden Schläuche für Ihre Anwendung sowie bei der Problembehandlung unterstützen und Ihnen erklären, wie Sie Ihre Schläuche richtig warten, um die Leistung Ihres Fluidsystems zu maximieren.

Hoses and Flexible Tubing Categories

Metal Core Hose

- Flexible Metal Hose, FJ Series

- Flexible Metal Hose, FL Series

- Flexible Metal Hose, FM Series

- High-Pressure Metal Hose, FX Series

- Metal Hose, AH Series

PTFE and PFA Core Hose

- PFA Core Hose Smooth Bore

- PTFE Core Hose Convoluted

- PTFE Core Hose Smooth Bore with 316L SS Convoluted Cover

- PTFE Core Hose Smooth Bore, B-Series

- PTFE Core Hose Smooth Bore, F-Series

Thermal Loop Program

Swagelok's thermal loop management program optimizes yield in semiconductor wafer manufacturing by preventing condensation and improving chiller hose performance.

Schläuche und flexible Rohre—Kataloge

Das Angebot von Swagelok umfasst Innenschlauchwerkstoffe aus Metall, PTFE, Thermoplastik und Gummi, Schlauchgrößen von 1/8 bis 2 Zoll sowie eine große Auswahl an zölligen und metrischen Endanschlüssen. In der hier bereitgestellten Produktliteratur finden Sie ausführliche Produktinformationen zu Werkstoffen, Drücken, Temperaturen, Werkzeugen und Zubehör sowie weitere Optionen wie ECE R110-zugelassene Schläuche und Schlauchkennzeichnungen.

■ コア材質:メタル、PTFE、PFA、ビニール、ナイロン、ポリエチレン、ゴム/■ ホース径(呼び径)サイズ:1/8 インチから2 インチまで/■ 豊富なエンド・コネクション(インチ・サイズ/ミリ・サイズ)/■ 長さ:ユーザー指定可能/■ オプション:カバー、タグ、テストなど

Schlauchberatung von Swagelok®

Erhalten Sie Tipps zur Auswahl der richtigen Schläuche sowie zur Installation, Inspektion und Wartung. So verlängern Sie die Lebensdauer und Leistung Ihrer Schläuche und minimieren die Kosten.

Erfahren Sie mehr zum Thema SchlauchmanagementSwagelok-Ressourcen für Sie zusammengestellt

In drei Schritten zu sicheren Schläuchen und geringeren Anlagenkosten

Die Sicherheit industrieller Schlauchsysteme spielt bei der regelmäßigen Anlageninstandhaltung oft nur eine untergeordnete Rolle. Allerdings müssen auch Schläuche regelmäßig geprüft werden, denn Leckagen und Verschleiß können sich zu einem ernsthaften Risiko für Ihre Anlage entwickeln. Erfahren Sie, wie Sie gefährliche Situationen vermeiden und gleichzeitig die Betriebskosten senken.

Wie Sie mithilfe eines Wartungsplans für industrielle Schläuche wesentliche Kosteneinsparungen erzielen

Wenn Sie in der Lage sind, den richtigen Zeitpunkt für den Austausch industrieller Schläuche zu erkennen, können Sie unter Umständen immense Wartungskosten im vierstelligen Bereich einsparen. Erfahren Sie, wie Sie Ihre Systeme auf den Prüfstand stellen und mit einem vorbeugenden Wartungsplan die Funktionsfähigkeit Ihrer Schläuche gewährleisten.

Austausch von industriellen Schläuchen: Überlegungen zur Auswahl des richtigen Schlauchinnenwerkstoffs

Bei der Auswahl von industriellen Schläuchen für Ihr Fluidsystem sollten Sie mit der innenliegenden Schicht beginnen, dem Innenschlauch. Erfahren Sie von den Experten von Swagelok, was Sie bei der Auswahl des richtigen Schlauchs für Ihre Anwendung beachten sollten, und erhalten Sie wichtige Informationen zu den Werkstoffen und zum Wandaufbau von Innenschläuchen.

Tipps zur Auswahl der passenden Schlauchverstärkung

Industrielle Schläuche sind in der Regel mit einer Verstärkung ausgestattet, die für eine längere Haltbarkeit und höhere Leistungsfähigkeit des Schlauchs sorgt. Erfahren Sie mehr über die unterschiedlichen Arten von Verstärkungen und welche für Ihre Fluidsystemanwendung am besten geeignet ist.