Swagelok® 튜브 피팅 및 어댑터

재조립 후에도 누설 없는 밀폐 성능, 탁월한 튜브 그립, 진동 내성을 제공하는 2-페럴 튜브 피팅으로 누설과 가동 중단을 줄여 보십시오.

튜브 피팅 | 설치가 간편하므로 설치 작업자의 피로를 줄일 수 있습니다.

튜브 어댑터 | 다양한 연결구를 지원하며 까다로운 정렬 문제를 해소하는 데 유용합니다.

Swagelok 피팅은 다양한 산업 전반에서 다른 제품에 비해 누설 위험과 많은 비용을 초래하는 가동 중단을 줄이는 데 뛰어납니다. 첨단 후위 페럴 구조는 응력을 격리하여 진동, 굽힘, 변형에 견딜 수 있으며, 특허 기술인 탄화 공정으로 내식성 저하 없이 강도가 보강되었습니다. 설치와 재조립이 쉬운 Swagelok 피팅은 다른 제품보다 필요한 노력이 더 적습니다.

튜브 피팅과 어댑터 피팅은 화학적 호환성을 보장할 수 있도록 다양한 합금으로 공급되며, 올바른 설치에 필요한 전문가 강의 교육이 제공됩니다. Swagelok 튜브 어댑터는 다른 어떤 Swagelok 튜브 피팅과도 함께 사용할 수 있으므로 전용 엘보우 및 티를 비축할 필요가 없습니다. 316 스테인리스강 및 316 Ti 스테인리스강 합금 튜빙과 함께 사용되는 스테인리스강 Swagelok 튜브 피팅은 ECE R110 요구 사항에 따른 테스트를 거쳤으며 EC-79 인증 제품도 공급 가능합니다. Swagelok은 NACE MR0175/ISO 15156 및 MR0103의 금속공학적 요구 조건을 충족하는 재질의 피팅을 공급합니다. 또한, 2507 및 6MO 합금으로 제조된 피팅은 기본적으로 NORSOK M-630 및 M-650 규격을 준수합니다.

チューブ継手/アダプターのカテゴリー

スペアー・パーツ/アクセサリー

チューブ継手の交換用部品/アクセサリー(フロント・フェルール、バック・フェルール、ナット、ガスケット、Oリング、ギャップ検査ゲージ、レンチなど)を幅広く取り揃えています。

バルクヘッド

バルクヘッド・チューブ継手/アダプター継手を使用すると、隔壁用途にてチューブを接続することができます。アプリケーションに合わせて、さまざまなサイズやエンド・コネクションを選ぶことができます。

差し込み溶接継手

差し込み溶接チューブ継手を使用すると、小口径流体システムにおいてアライメント(位置合わせ)を適切に行うことができます。さまざまなサイズや形状を選ぶことができ、幅広いアプリケーションに適合します。

튜브 피팅 및 어댑터 카탈로그

1/16~2인치 및 2~50mm 튜브 크기와 다양한 구성으로 공급되는 Swagelok 튜브 피팅과 튜브 어댑터는 케미칼 가공 및 Sour 가스를 포함한 광범위한 애플리케이션에서 탁월한 내부식성을 제공하는 다양한 재질로 제조됩니다. 여기에 있는 제품 자료에서 구성 재질, 압력 및 온도 등급, 공구 및 액세서리, 설치 지침을 포함한 자세한 제품 정보를 확인하실 수 있습니다.

■ 塩化物環境下でも優れた耐食性/■ アドバンス・バック・フェルール構造による優れたシール性能/■ 従来のSwagelok® チューブ継手と同様、ゲージによる締め付け度の確認が可能/■ ハンド・ツールを使用して容易に取り付け可能/■ サイズ:1/4 インチから3/4 インチまで

■ 計装用マニホールド V/VB/VLシリーズ(2バルブ/3バルブ/5バルブ)/■ ダイレクト・マウント用マニホールド VEシリーズ(2バルブ/3バルブ/5バルブ)/■ リモート・マウント用マニホールド(2バルブ)/■ 計装用モジュラー85システム/■ API 624による低排出認証付き製品もございます(ダイレクト・マウント用/リモート・マウント用マニホールドおよびモジュラー85システムの場合)

■ 液体クロマトグラフ用/ガス・クロマトグラフ用/■ 材質:316ステンレス鋼/■ サイズ: 1/16~1/2 インチ

■ 材質:ステンレス鋼(Oリング:フルオロカーボンFKM製)/■ 取り付けや取り外しを繰り返し行っても、常に信頼性の高い優れたシール性能を実現/■ チューブ外径サイズ:1/16 インチから1 1/2 インチまで

■ チューブ外径サイズ:1/16 インチから2 インチまで、2 mmから50 mmまで/■ ゲージによる一貫した締め付け度の確認が可能(初回取り付け時)/■ 取り外しや再取り付けが容易/■ 各種材質、多様な形状/■ 高い信頼性と性能

■ サイズ:1/16 インチから1 インチまで/■ ねじタイプ:NPT、JIS/ISO、SAE/■ 材質:316 ステンレス鋼、炭素鋼、真ちゅう、6-Moly、合金625、合金825、合金2507

중압 및 고압 피팅 둘러보기

11,000psi가 넘는 압력을 다룰 수 있는 피팅을 찾고 계십니까? 최대 22,500psi(1,551bar)의 애플리케이션에 사용 가능한 Swagelok FK 시리즈 중압 튜브 피팅과, 최대 60,000psi(4,134bar)의 애플리케이션에 사용 가능한 콘 & 쓰레드 피팅에 대해 읽어보십시오.

더 높은 압력 등급 찾기関連資料/コラム記事

継手の基礎:ねじのサイズとピッチを識別する

経験豊かなベテランでも、ねじを識別するのは容易ではありません。今回は、継手のねじのサイズとピッチを、ノギス、ねじピッチ・ゲージ、ねじ識別ガイドで識別する方法を紹介します

圧縮継手による中圧オイル/ガス・アプリケーションの最適化

中圧オイル/ガス・アプリケーションのトップサイド設備では、従来のコーン&スレッド接続よりも圧縮継手の方が取り付けスピードやパフォーマンスにおいて優れていることを紹介します。

瀋陽ブロワー・ワークス・グループ、安全性と信頼性の向上を実現

瀋陽ブロワー・ワークス・グループ・コーポレーションは、スウェージロック上海のサポートによって、顧客のアプリケーションの一貫性、信頼性、コスト削減を実現したばかりか、自社の安全性および生産効率も向上させることができました。

チューブ・アダプターでアライメント(位置合わせ)の問題を解消する

チューブ・アダプターを使用することで、難しいアライメント(位置合わせ)の問題を解消し、在庫を削減することができます。Swagelok®チューブ・アダプターを使用して、アライメントの問題を解決し、漏れの無いシールを実現する方法を動画でご覧ください。

1947年に創業して以来、スウェージロックはあらゆる産業の流体システム・アプリケーションで使用されるチューブ継手技術の発展をリードしてきました。

革新的なチューブ継手について語るスウェージロックの創業者の動画をご覧ください

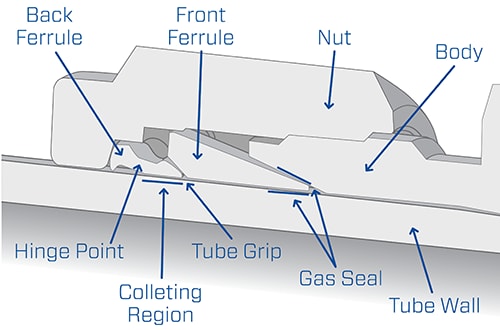

Swagelokチューブ継手は、誕生から75年以上経った今でも、そのユニークなhinging-colleting機能により、長期にわたって漏れの無い性能を発揮する継手として高い信頼を得ています。メカニカル・グリップ構造を採用し、hinging-colleting機能を使用することで、以下の3つのポイントにおいて最適なパフォーマンスを実現します:

チューブ・グリップ

Hinging-colleting機能により、チューブへの密着性やグリップ性能が向上します。

ガス・シール

フロント・フェルールの研磨作用により、チューブおよびボディ・テーパー面に集中的に接触するゾーンが形成されるため、更に強力なシールが実現します。

耐振性

Hinging-colleting機能により、より効果的にチューブ・グリップ部の応力上昇を分散させることで、曲げ、たわみ、振動にも耐えることができます。

Swagelok®チューブ継手のデザイン

サイズが1/4~1 インチ、6~25 mmのステンレス鋼製Swagelokチューブ継手には、アドバンス・バック・フェルール構造によるhinging-colleting機能を標準採用しており、漏れのないチューブ接続を確実に行うことができます。これらのサイズの継手では、表面硬化処理(特許)を行い、くぼみ付きのなだらかな独自の形状(特許)を備えたSwagelokバック・フェルールを使用しています。Hinging-colleting機能付きのバック・フェルールにより、トラディショナルSwagelokチューブ継手のフェルールの優れた性能を更に高めています。