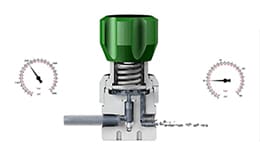

Swagelok® Tank Blanketing Pressure Regulators

Designed to maintain constant inert gas pressure in unique applications.

Get Help Selecting RegulatorsSwagelok tank blanketing regulators are crucial for ensuring the safety of operators and bystanders around storage tanks containing hazardous fluids. They maintain consistent pressure levels of inert gases in the vapor space, preventing hazardous vapors from escaping.

Tank blanketing regulators reduce safety risks associated with pressure-sealed tanks.

- TBRS series regulators allow gas into the tank to maintain constant pressure, preventing collapse during pump-out

- TBVS series back-pressure regulators vent excess pressure to vapor recovery systems, preventing accidental emissions

These regulators offer precise pressure control in tank blanketing applications. They feature fine-pitched threads on set-pressure springs for enhanced adjustability, a highly sensitive diaphragm-sensing mechanism for accurate pressure detection, and an external feedback loop that improves regulator performance. Additionally, they are built to withstand harsh environments, utilizing 316L stainless steel for components like feedback tubes, regulator bodies, and poppet housings, ensuring corrosion resistance and long-term durability.

Specifications

| Material | 316L stainless steel construction |

| End Connection Sizes | 1/2, 1, and 2 in. |

| Working Pressure | up to 232 psig (16.0 bar) |

| Pressure Control Ranges | 0.07 to 0.14 psig (2.0 to 4.0 in. H2O, 5 to 10 mbar) through to 0.72 to 11.6 psig (20 to 321 in. H2O, 50 to 800 mbar) |

| Flow Coefficient (Cv) | 0.20, 0.30, 1.00 |

| Temperature | from –4 to 212°F (–20 to 100°C) |

Tank Blanketing Regulators Catalogs

Find comprehensive details on our tank blanketing regulators covering construction materials, accessories, pressure, and temperature ratings.

■ タイプ:減圧用、蒸気回収用/■ 材質:316Lステンレス鋼/■ エンド・コネクション・サイズ:1/2 インチ、1 インチ、2 インチ/■ 最高使用圧力:1.60 MPa/■ 使用温度範囲:-20℃から100℃まで

Need Help Selecting the Right Regulators?

Evaluate the performance of various vaporizing regulators across diverse applications conditions using our Regulator Flow Curve Generator tool.

Find the Right RegulatorSwagelok Regulator Resources

Managing Supply Pressure Effect (SPE) in a Regulator

Supply pressure effect, also known as dependency, is an inverse relationship between inlet and outlet pressure variables within a regulator. Learn how to manage this phenomenon in your pressure regulators with tips from Swagelok.

철저한 테스트가 신뢰성 높은 레귤레이터 성능을 보장하는 이유

극한 조건에서 올바르게 작동하도록 제품을 설계하려면 어떤 테스트가 필요할지 궁금하십니까? 영하의 온도에서도 작동하는 Swagelok RHPS 시리즈 산업용 레귤레이터의 개발 과정을 따라가면서 어떻게 설계되는지 알아보십시오.

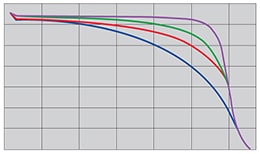

레귤레이터 유량 곡선을 평탄화하여 드룹(droop)을 줄이는 방법

드룹(droop)은 모든 감압 레귤레이터에서 발생하는 공통된 문제입니다. 다양한 돔 하중 레귤레이터 구성을 사용하여 드룹(droop)을 최소화하고 레귤레이터 유량 곡선을 평탄화하는 방법을 알아보십시오.

분석 계장 시스템에서 레귤레이터를 사용하여 시간 지연을 줄이는 방법

시간 지연 문제는 종종 분석 시스템에서 과소 평가되거나 오해를 받습니다. 이러한 문제를 완화하는 방법 중 하나는 압력 제어 레귤레이터를 사용하는 것입니다. 이러한 팁을 통해 분석 시스템의 시간 지연 문제를 관리하는 방법을 알아보십시오.