Swagelok® Gas Distribution Systems

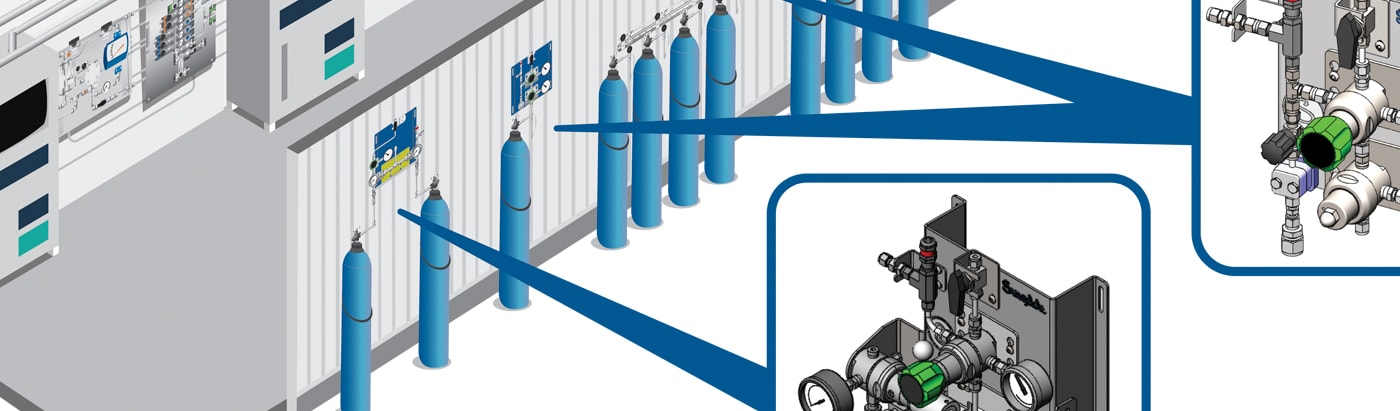

Gas distribution is a critical function for many industrial, research, and production facilities. Safely, reliably, and effectively delivering gases to where they are needed provide the foundation for a strong operation. Gas distribution systems work to deliver gases from a high-pressure source to the facility at the pressure and flow rate required by each application.

Contact a SpecialistSwagelok standard gas distribution panels come fully assembled and tested. They are easy to order from our application guide as single part numbers, minimizing the time your engineers spend on specification and procurement of new systems.

Swagelok modular panels feature minimal threaded connections to reduce potential leak points, and they are intuitively labeled to promote safe, simple use, and maintenance, and are backed by the Swagelok Limited Lifetime Warranty.

Learn more about Swagelok® Gas Distribution Systems

Swagelok gas distribution systems are built around one or a series of pressure regulation steps, and may include four subsystems:

- Swagelok® source inlet (SSI)

- Swagelok® gas panel (SGP)

- Swagelok® changeover (SCO)

- Swagelok® point-of-use (SPU)

Swagelok® Source Inlet (SSI)

The source inlet establishes a connection between the high-pressure gas source and the distribution system. It is important the inlet is built with appropriate cylinder connections, hoses, tubing, filters, and vent, purge, and relief functions to ensure that gas can be safely fed into the primary gas pressure control or automatic changeover. For a single gas cylinder, the assembly can be as simple as a hose and connector, while multiple cylinders may require a manifold incorporating many hoses and valves. Swagelok offers highly configurable options to purge or vent gases when changing bottles, always ensuring operator safety, as well as an available option to vent individual lines to maximize uptime.

Swagelok advisors will ensure all componentry is included and correctly specified with minimal connection points, hoses that do not drop to the ground, and properly supported components. Additionally, we can advise when certain gases may require the use of special hoses.

Swagelok® Gas Panel (SGP)

The SGP completes the first pressure reduction of the source gas and ensures it is delivered at the correct flow rate to the next stage of the system. Pressure reduction is accomplished in either one stage with a single pressure regulator or two stages through a dual pressure regulator arrangement.

Swagelok offers modular panels that are easy to service as any part can be detached via a Swagelok connection, so the panel never needs to be removed, as well as options implemented around the regulator and valves for color-coding if required for your site. Swagelok can also help you understand where a two-stage regulator is required.

Swagelok® Changeover (SCO)

The automatic changeover system seamlessly switches from one gas source to another to ensure an uninterrupted supply. This is accomplished through staggered set points of two pressure regulators, allowing the system to continue to operate as the primary gas source is changed. The changeover station allows for specified changeover set points to reduce wasted gas left in cylinders.

Swagelok offers more assurance the changeover point remains constant, as well as optional line regulation if your system incorporates a point of use regulator downstream—this can eliminate the additional cost of a regulator on the SCO. Swagelok specialists can help your team better understand system functionality, troubleshoot, and maintain operations.

Swagelok® Point-of-Use (SPU)

The point-of-use provides the critical last stage of pressure control prior to the gas being used. These typically have a pressure regulator, gauge, and isolation valve. Point-of-use systems offer a convenient and accurate method of adjusting pressure to meet test bench or equipment needs.

Swagelok offers standardization and consistent operation at the point-of-use; flat plate, bottom mount, top mount, and wall mount options; and a compact design. A Swagelok specialist can show you hidden savings, like how a single-stage SGP can be used to minimize cost where varying line pressure between the SGP and SPU is acceptable.

스웨즈락 애플리케이션 가이드 보기

스웨즈락 조립체에 관한 자세한 정보 찾기

가스 분배 시스템은 각 기계가 요구하는 압력과 흐름율에 맞추어 가스를 고압 가스원에서 시설로 전달하는 것이 목적입니다. 대부분 하나 또는 일련의 압력 제어 단계 주위에 설치되고, 가스 분배 시스템에는 네 가지의 대표적인 서브 시스템이 있습니다. 가스원 입구 연결부, 일차 가스 압력 제어, 자동 변환, 그리고 이용 현장입니다. 이 가이드는 스웨즈락의 가스 분배 시스템에 대한 정보를 제공하고 있습니다.

그랩 샘플링은 분석을 위해 유체 또는 가스 샘플을 실험실에 보내기 위해 해당 샘플을 채취하는 것입니다. 완전하게 문서화된 유체 샘플링 및 제어 시스템을 위해 Swagelok 애플리케이션 솔루션을 사용하면 일관성 있는 운영이 가능합니다.

산업 가스 분배 시스템 이해하기

산업 가스 분배 시스템이 얼마나 사용 및 유지가 쉬운지와 같은, 산업 가스 분배 시스템의 효율성에 가장 바로 영향을 미치는 설계 요인에 대해 알아보고 가동 효율성을 높이십시오.

백서 보기귀하를 위해 선별된 스웨즈락 리소스

사례 연구: 가스 라인 200개. 종합적인 솔루션 1개.

이 영국의 주요 화학 회사는 다양한 특수 가스를 사용하여 연구 및 개발을 수행합니다. 이 회사는 스웨즈락의 가스 분배 프로그램을 적극 이용하여 시스템의 안전성을 강화하고 새로운 효율성을 실현했습니다.

如何通过改善气体分配来减少您的维护支出

了解易用型气体面板和整体更高效的气体分配和输送系统如何帮助实验室、精炼厂和其他设施降低维护成本。

问答:如何通过高效的气体分配来降低成本并提高安全性

了解可能会妨碍重要气体分配系统的安全与效率的常见挑战以及对这些系统进行专业评估如何提供长期价值的信息。

提高气体分配系统的安全性和效率

气体分配系统对于帮助实验室、测试中心和工业设施以高效率运行至关重要。了解优化气体传输系统的健康,安全和降低成本,使你的团队走向成功。