Déverseurs à dôme pour process Swagelok®

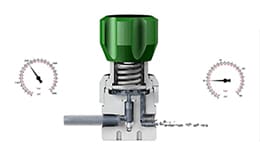

En limitant le phénomène de baisse graduelle de la pression de sortie, les régulateurs de pression à dôme produisent des pressions de sortie très stables, quelles que soient les variations de la pression d’entrée ou du débit.

Obtenir de l’aide concernant les régulateurs de pression pour processРегуляторы обратного давления подходят для широкого спектра промышленных систем, где возможно ручное или дистанционное управление регулятором. Технологические куполовидные редукторы отлично справляются с поддержанием постоянного давления на выходе, даже при скачках давления или расхода на входе. Стабильность достигается благодаря механизму управления куполом, который устраняет необходимость в установочной пружине.

Такие универсальные регуляторы могут предусматривать различные функции для удовлетворения конкретных запросов, а именно:

- Варианты подключения манометров

- Пилотные регуляторы

- Системы внешней обратной связи

- Особые процессы очистки

Для повышения уровня автоматизации купольные регуляторы могут работать в паре с электронными пилотными клапанами. Данная конфигурация снижает необходимость в ручной настройке и позволяет быстро реагировать на изменение условий в системе.

При выборе регуляторов давления узнайте у поставщиков о методах подтверждения их технических характеристик. Регуляторы, прошедшие тщательные испытания, с большей вероятностью выдержат сложные и долгие условия эксплуатации. Точность конструкции регулятора и тщательные лабораторные испытания могут стать решающими факторами в успехе всего проекта.

Каталоги технологических куполовидных регуляторов обратного давления

Получите подробные сведения о продукции, в том числе о материалах изготовления, номинальных параметрах давления и температуры, вариантах исполнения и вспомогательных принадлежностях.

Caractéristiques : détendeurs ; déverseurs ; modèles à ressort, à dôme, pneumatiques ; raccordement d'extrémité de 1/4 à 4 po ; pressions de service jusqu'à 700 bar (10 150 psig) ; températures de –20 à 80°C (–4 à 176°F)

Нужна помощь с выбором подходящего регулятора?

Сравните характеристики регуляторов в разных условиях эксплуатации с помощью нашего калькулятора для расчета параметров расхода.

Поиск подходящего регулятораРесурсы Swagelok специально для вас

Минимизация эффекта нагнетаемого давления (SPE) в регуляторе

Эффект нагнетаемого давления представляет собой обратную зависимость между значениями давления на входе и выходе регулятора. Узнайте, как минимизировать это явление в регуляторах от экспертов компании Swagelok.

Как тщательные испытания гарантируют надежность работы регулятора

Вы когда-нибудь задавались вопросом, какие испытания проходят изделия, предназначенные для работы в экстремальных условиях? Загляните в лабораторию и узнайте историю разработки промышленных регуляторов серии RHPS для эксплуатации при сверхнизких температурах.

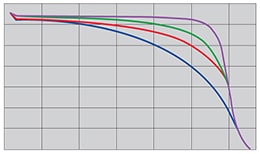

Как выпрямить кривую расхода регулятора, чтобы снизить потери давления

Потеря давления является проблемой для каждого редуктора. Узнайте, как свести к минимуму такой эффект и выпрямить кривую расхода с помощью целого ряда вариантов куполовидных регуляторов.

Применение регулятора для уменьшения временной задержки в аналитической контрольно-измерительной системе

Временную задержку в аналитических системах часто недооценивают или неправильно интерпретируют. Одним из способов уменьшить эту задержку является регулятор, управляемый давлением среды. Изучите приведенные рекомендации, которые помогут узнать, как уменьшить временную задержку в аналитической системе.