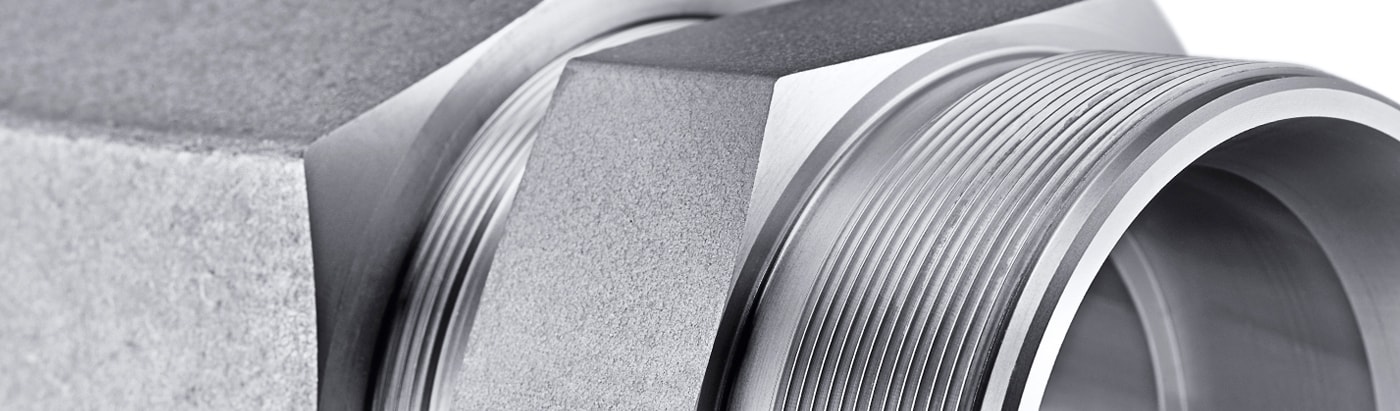

Swagelok® Fittings

Swagelok fittings provide industrial fluid system operators with the reliability, ease of installation, and leak-tight performance needed to keep processes and equipment operating safely and efficiently.

View All FittingsSince the introduction of the Swagelok® tube fitting in 1947, industrial professionals have relied on Swagelok fittings to achieve leak-tight connections in their analytical, instrumentation, and small-bore process fluid systems. Whether you need fittings for corrosive environments, extreme temperatures, or high pressure, we offer reliable options to help you build connections you can trust. We offer a complete portfolio of fittings available in a variety of alloy materials for a wide range of industrial applications, including those with specialized requirements.

Swagelok fittings are held to high quality standards made possible by highly controlled processes, providing users peace of mind when integrating these versatile, high-performance fittings into their fluid system designs. Should you need technical support or training to make the best use of these products in your systems, help is available at nearly 200 authorized Swagelok sales and service locations across the globe.

Looking for fittings selection and installation advice?

Catégories de raccords

PFA 가는 나사(Fine Thread) 확관형 피팅

PFA 피팅은 반도체 생산과 같은 고순도 애플리케이션을 운영하는 데 필요한 인장 강도, 열 안정성, 크리프(Creep) 내성을 제공합니다.

Raccords VCR® à étanchéité de surface avec joint métallique

모든 Raccords VCR® à étanchéité de surface avec joint métallique 필터링

VCO O-링 면 밀폐 피팅

- Aufschraubverschraubungen

- Ersatzteile und Zubehör

- Gerade Einschraubverschraubungen

- Gerade Verschraubungen

- Schottverschraubungen

용접 피팅

- Hochreine Micro-Fit, Rohrstumpfschweißfittings

- Muffenschweißfittings

- Schweißadapter

- Stumpfschweißfittings

중압 튜브 피팅

- Aufschraubverschraubungen

- Ersatzteile und Zubehör

- Gerade Einschraubverschraubungen

- Gerade Verschraubungen

- Schottverschraubungen

Fittings Catalogs

Locate detailed product information, including materials of construction, pressure and temperature ratings, options, and accessories.

The proven Swagelok® tube fitting design manufactured from corrosion-resistant alloy 2507 with NORSOK M0630 and M-650 compliance standard, NACE MR0175/ISO 15156 optional.

Features: Available in 1/4, 3/8, 1/2, 3/4 and 1 in. tube sizes; PFA and PVDF nut options; A wide variety of configurations

계장용, 직접 장착형, 원거리 장착형 매니폴드 및 모듈식 시스템 , V, VB 및 VL 시리즈 2-, 3- 및 5-밸브 계장용 매니폴드, VE 시리즈 2-, 3- 및 5-밸브 직접 장착형 매니폴드, 2-밸브 원거리 장착형 매니폴드, Mod 85 모듈식 계장용 시스템

FK and IPT Series Products Cone and thread or medium-pressure tube fitting connections Excellent corrosion resistance in chloride-containing environmentsManufactured to meet NORSOK and NACE® MR0175/ISO15156

1/8 ~ 1 in. 및 6 ~ 18 mm; 316, 316L, 316L VAR 및 316L VIM-VAR 스테인리스강 재질; 수동 또는 자동 용접기용 피팅

스테인리스강 구조, 탄화플루오르 FKM O-링; 안정적이고 반복 가능한 밀폐 성능; 1/16 ~ 1 1/2 in. 인치 튜브 크기 제공

Features: Metal components are machined from 316 stainless steel for use in rugged environments; Molded thermoplastic insulation with excellent electrical, chemical, and ultraviolet resistance and low water absorption maintains dielectric strength and integrity over a wide range of operating and climatic conditions; Gaugeable Swagelok® tube fitting or tapered pipe thread end connections (NPT/BSP) provide direct connection to tubing or piping system.

특징: 플랜지 파이핑 시스템에서 튜빙 시스템까지 나사 및 용접점 없는 변환; ASME, DIN, EN, 및 JIS 표준에 맞는 플랜지 타입; 원 피스 통합 기계 주조 몸체; 50mm 및 2in.까지의 Swagelok® 튜브 피팅 말단 연결구 사용 가능

1/16 in. 부터 2 in. 및 2 mm 에서 50 mm; 최초 설비 시 일관된 측정가능성; 분리 및 재조립이 용이함; 다양한 재질 및 형태

1/16 in. 부터 1 in. 및 6 mm 에서 18 mm; 고순도 스텐레스강; 최초로 설계된 진정한 VCR 제품

특징: 316 스텐레스강 구조; 537°C (1000°F)까지의 온도; 중압 (MP) 피팅, 크기—1/4 ~ 1 in., 압력 등급—최대 20 000 psig (1378 bar); 고압 (HP) 피팅, 크기—1/4 ~ 9/16 in., 압력 등급—최대 60 000 psig (4134 bar); NACE® MR0175/ISO15156 적합

Features: Temperatures from 70 to 400°F (20 to 204°C); Working pressures up to 275 psig (18.9 bar); Sizes from 1/8 to 1/2 in.

Features: Suitable for liquid or gas chromatography; 316 stainless steel construction; Offered in sizes from 1/16 to 1/2 in.

PGI 시리즈 40, 50, 63, 100, 115 및 160 mm (1 1/2, 2, 2 1/2, 4, 4 1/2 및 6 in.) 다이얼 크기; ASME, EN 및 JIS 에 따른 정확도; Swagelok® 튜브 어답터를 비롯한 다양한 연결구 제공; 중앙 후면, 하단 후면 및 하단 장착 구성; 스텐레스강 및 강화 플라스틱 구조; 액체 충전 및 비충전 형태로 제공

The Swagelok® Tube Fitting Advantage

Swagelok tube fittings are designed to meet your highest expectations for safety and dependability, featuring proven design, precise manufacturing, and superior raw materials.

Discover the AdvantageSwagelok Resources Curated for You

An Introduction to Fittings: Identifying Thread Size and Pitch

Even the most seasoned professionals can experience difficulty identifying threads. Swagelok product manager Andy Hitchcock explains how to identify thread size and pitch on your fittings using a caliper, pitch gauge and thread identification guide.

How Shenyang Blower Works Group Improved Safety and Reliability

Learn how Swagelok Shanghai has helped Shenyang Blower Works Group Corporation achieve consistency, reliability, and cost savings for its customers while improving its own safety and production efficiency.

Swagelok Tube Fitting Installation

This video demonstrates the integral steps for installing Swagelok tube fittings, which have earned a global reputation for consistency, quality, and reliability.

Swagelok Fittings

When the world’s most respected companies want to make lasting connections, they turn to Swagelok. We have established the standards for tube fitting performance in terms of leak-tight integrity, ease of installation, availability and support services. Our two-ferrule, stainless-steel tube fitting has earned a global reputation for consistency, quality, and reliability. This reputation is supported by our continuous product improvement efforts and by the fitting’s performance in thousands of diverse applications.