Swagelok® 열가소성 호스

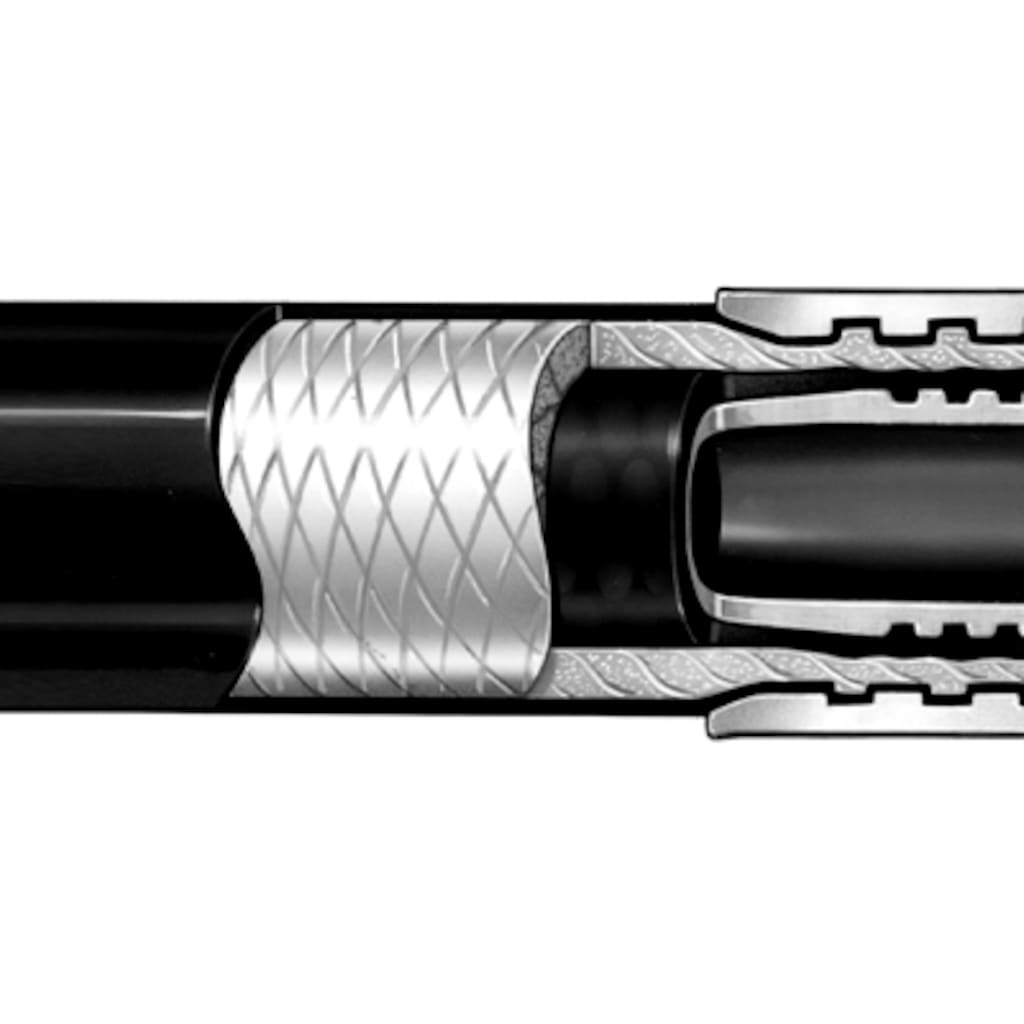

Swagelok® 열가소성(나일론 및 폴리우레탄) 코어 호스는 고 임펄스 압력 사이클과 역동적인 동작을 견딜 수 있도록 견고하게 설계되어, 유압 및 압축 천연 (CNG) 차량 충전 애플리케이션에서 강력한 성능을 제공합니다.

열가소성 호스 보기Swagelok 열가소성 호스는 유압 펌프 및 볼 밸브 애플리케이션에 사용할 때 강력한 압력 임펄스 성능을 제공합니다. 이 호스는 고압 변화에 대한 내성으로 인해 특히 CNG 차량 충전 애플리케이션에서 탁월한 성능을 발휘하며, NGV 및 ECE R110 대체연료 인증 모델도 공급 가능합니다.

Swagelok 고성능, 다목적 주름 없는 나일론 코어 호스는 다양한 연결구를 통해 유압, 천연 가스 및 기타 범용 산업용 애플리케이션에 빠르고 안전하게 연결할 수 있습니다. 매끄러운 내부 벽이 정밀도와 청정도를 확보하는 데 필요한 유량 제어 기능과 강화된 배출 성능을 제공하며, 폴리우레탄 커버가 내마모성을 제공합니다.

Swagelok 폴리에틸렌 호스 코어 재질은 FDA 21 CFR Part 177 1520 및 NSF-51 규격을 준수하므로, 식품, 유제품, 식수 애플리케이션에서 신뢰성 높은 옵션입니다. 내부 섬유 편조 보강층이 압력 밀폐 성능과 유연성을 높여줍니다. 폴리우레탄 커버는 내마모성을 제공하며 수분 잔류와 시스템 오염을 방지합니다.

열가소성 호스 선택에 도움이 필요하십시까?

Thermoplastische Schläuche—Kategorien

Endanschlüsse

Dank der zahlreichen Endanschlüsse in unterschiedlichen Größen zeichnen sich die Swagelok®-Schläuche durch eine einfache Montage vor Ort aus.

Nylonschlauch

Die Nylonschläuche der Serien 7R und 8R eignen sich für hydraulische Anwendungen, bei denen Ausgasungen berücksichtigt werden müssen.

Schlauch mit Polyethylen-Innenschlauch

Die Polyethylen-Innenschläuche von Swagelok erfüllen die FDA-Anforderungen und verhindern Verunreinigungen in Lebensmittel-, Molkerei- und Wasseranwendungen.

호스 및 플렉시블 튜빙 카탈로그

구성 재질, 압력 및 온도 등급, 옵션, 액세서리를 포함한 자세한 제품 정보를 찾을 수 있습니다.

Innenschlauchwerkstoffe aus Metall, PTFE, PFA, Vinyl, Nylon, Polyethylen und Gummi; Schlauchnenngrößen 1/8 bis 2 Zoll; Vielzahl von zölligen und metrischen Endanschlüssen; Speziallängen sind erhältlich; Optionale Umhüllungen, Kennzeichnungen und Prüfungen

Swagelok® 호스 자문 서비스

호스 선정, 설치, 검사, 유지보수 절차를 개선하여 호스 수명과 성능을 개선하고 공정 비용을 절감하는 방법을 알아보십시오.

호스 관리에 대해 알아보십시오Swagelok Resources Curated for You

3 Steps to Hose Safety & Lower Plant Costs

Industrial hose safety is often deprioritized during regular plant maintenance. It is important hoses receive the attention they deserve—leaks and wear can put your facility at risk. Learn tips to avoid dangerous situations while lowering plant costs.

How an Industrial Hose Maintenance Plan Could Save Your Plant Thousands

Knowing the proper time to replace your industrial hoses can save your plant thousands in maintenance costs. Learn how to evaluate your systems and develop a preventive maintenance plan to manage the health of your hoses.

Industrial Hose Replacement: Core Tube Material Considerations

When selecting an industrial hose, the first place to start is the core tube—the hose’s innermost layer. Learn how to select the ideal hose for your application with information on core tube materials & wall construction from the experts at Swagelok.

How to Select the Right Hose Reinforcement

Industrial hoses typically contain critical reinforcement layers that contribute to longevity and performance. Learn about different reinforcement layer types and which is best suited for different fluid system applications.