Racores para Tubo y Adaptadores Swagelok®

Reduzca las fugas y los tiempos de parada con los racores para tubo de doble férula que proporcionan un cierre estanco, un agarre superior del tubo y resistencia a las vibraciones tras repetidas reutilizaciones.

Racores para tubo | Fáciles de instalar, ayudan a reducir la fatiga del instalador.

Adaptadores para tubo | Diversifican las conexiones y ayudan a eliminar los difíciles problemas de alineación.

Los racores Swagelok superan a los demás en la reducción del riesgo de fugas y paradas costosas en muchas industrias. El avanzado diseño de la férula trasera aísla el punto de máxima tensión para resistir la vibración, el doblado y la deflexión, mientras que el proceso patentado de carburización aporta mayor solidez sin sacrificar la resistencia a la corrosión. Fáciles de instalar y reutilizar, los racores Swagelok requieren menos esfuerzo que otras alternativas.

Los racores para tubo y adaptadores están disponibles en distintas aleaciones para asegurar la compatibilidad química, y además se ofrece formación impartida por expertos para su correcta instalación. Los adaptadores a tubo Swagelok se pueden utilizar con cualquier otro racor Swagelok, eliminando la necesidad de tener en stock codos y tes especiales. Los racores Swagelok de acero inoxidable utilizados con tubo de acero inoxidable 316 y aleación de acero inoxidable 316 Ti, han sido probados según los requisitos de ECE R110 y también están disponibles con certificado EC-79. Swagelok tiene disponibles racores que cumplen los requisitos metalúrgicos de NACE MR0175/ISO 15156 y MR0103 También, los racores fabricados con la aleación 2507 y 6MO cumplen de forma estándar las normas NORSOK M-630 y M-650.

Категории трубных фитинги и переходников

Запасные части и вспомогательное оборудование

Подробнее о запасных частях и аксессуарах для трубных фитингов—передние и задние обжимные кольца, гайки, прокладки, уплотнительные кольца, щупы для контроля зазоров, гаечные ключи и многое другое.

Защитные фильтры

Узнайте больше о фитингах с защитным фильтром (т.н. протекторы дренажных отверстий), оснащенных проволочной сеткой для защиты от попадания в систему насекомых и других посторонних предметов.

Колпаки и заглушки

Колпачки и заглушки для трубных фитингов из различных материалов и разных размеров позволяет обеспечить герметичность и повышенную безопасность системы в широком диапазоне условий эксплуатации.

Муфты

Прямые муфты, и угловые отводы, тройники и крестовины из различных материалов и размеров обеспечивают необходимую опору и превосходную устойчивость к вибрации.

Муфты с малой застойной зоной

Трубные фитинги Swagelok® с малой застойной зоной разработаны для надежного повышения общей эффективности промышленных газовых и жидкостных систем, даже в жестких условиях эксплуатации.

Переходники с нулевым объемом

Ознакомьтесь с переходниками для трубных фитингов нулевого объема, разработанными с целью повышения общей эффективности вашей газовой или жидкостной системы.

Плавкие вставки

Плавкие трубные переходники улучшают общую безопасность промышленных газовых и жидкостных систем за счет сброса давления в атмосферу при заданной температуре.

Редуцирующие переходники

Переходные прямые отводы и тройники фитингов из различных материалов и обеспечивают простоту установки и возможность надежного контроля степени затяжки.

С монтажной гайкой

Трубные фитинги и переходники с монтажной гайкой делают возможным соединение через переборку, и предлагаются в различных размерах и типах соединения.

Соединители для проходного канала

Соединители Swagelok® для проходного канала обеспечивают соединение «фитинг в фитинг», промеряемость при начальном монтаже, легкость разъединения и повторной затяжки.

Соединители с внутренней резьбой

Доступные в различных материалах, размерах и конфигурациях фитинги на соединителях с внутренней резьбой обеспечивают герметичное уплотнение, устойчивое к вибрационной усталости.

Соединители с наружной резьбой

Доступные в различных материалах, размерах и конфигурациях фитинги на соединителях с наружной резьбой обеспечивают герметичное уплотнение, устойчивое к вибрационной усталости.

Трубные переходники

Прямые, угловые и тройниковые переходники обеспечивают соединение фитингов Swagelok® с различными типами торцевых соединений.

Фитинги под приварку враструб

Фитинги под приварку враструб обеспечивают необходимую соосность и центровку в системах малого диаметра. Предлагаем широкий ассортимент размеров и конфигураций для различных задач.

Catálogos de Racores para Tubo Galgables y Adaptadores

Disponibles en tamaños de tubo de 2 a 50 mm y de 1/16 a 2 pulg. y en una gran variedad de configuraciones, los racores para tubo Swagelok se fabrican en diversidad de materiales para ofrecer una resistencia superior a la corrosión en muchas aplicaciones, incluyendo procesos químicos y gases sulfurosos. Consulte información detallada sobre el producto, incluidos los materiales de construcción, las presiones nominales y las temperaturas, las opciones, herramientas y accesorios e instrucciones de instalación en la documentación del producto que se ofrece aquí.

The proven Swagelok® tube fitting design manufactured from corrosion-resistant alloy 2507 with NORSOK M0630 and M-650 compliance standard, NACE MR0175/ISO 15156 optional.

Приборные двух-, трех- и пятиклапанные блоки серий V, VB и VL; двух-, трех- и пятиклапанные блоки прямого монтажа серии VE; двухклапанные блоки выносного монтажа; модульные контрольно-измерительные системы Mod 85

Температура от 20 до 204 °C (от 70 до 400 ºF); Рабочее давление до 18,9 бара (275 фунтов на кв. дюйм, ман.); Размеры от 1/8 до 1/2 дюйма

Характеристики: пригодны для жидкостной и газовой хроматографии; конструкция из нержавеющей стали 316; предлагаются размеры от 1/16 до 1/2 дюйма.

Конструкция из нержавеющей стали, уплотнительное кольцо из фторуглерода FKM, Надежное повторяемое соединение, Предлагаются для трубок размером от 1/16 до 1 1/2 дюйма

Swagelok® tube fittings and tube adapters reduce the risk of costly system downtime with reliable tubing connections and are available in a variety of sizes and materials.

Размеры от 1/16 до 1 дюйма; Изготавливаются из нержавеющей стали марки 316, латуни и углеродистой сталиl; Резьбы NPT, ISO/BSP и SAE

Ver los Accesorios de Media y Alta Presión

¿Busca racores que puedan soportar presiones superiores a 11.000 psi? Conozca nuestros racores para tubo de media presión serie FK, diseñados para aplicaciones hasta 1551 bar (22.500 psi) y nuestros accesorios de cono y rosca para aplicaciones hasta 4134 bar (60.000 psi).

Encuentre Mayores Rangos de PresiónRecursos Swagelok Elaborados para Vd.

Introducción a los Racores: Identificación del Tamaño y Paso de la Rosca

Hasta para los profesionales más experimentados puede ser difícil identificar roscas. El director de producto Andy Hitchcock describe cómo identificar el tamaño y paso de las roscas de los racores con un calibre, una galga para roscas y la guía de identificación de roscas.

Optimización de las Aplicaciones de Petróleo y Gas a Media Presión con Racores de Compresión

Para las aplicaciones de media presión en las plataformas del petróleo y el gas, vea cómo los racores de compresión pueden ofrecer ventajas de velocidad de instalación y rendimiento en comparación con las conexiones de cono y rosca tradicionales.

Cómo el Grupo Shenyang Blower Works Mejoró la Seguridad y la Fiabilidad

Vea cómo Swagelok Shangai ha ayudado a Shenyang Blower Works Group Corporation a conseguir consistencia, fiabilidad y ahorro de costes para sus clientes, a la vez que ha mejorado su propia seguridad y eficiencia de producción.

Cómo los Adaptadores a Tubo Swagelok Pueden Eliminar los Problemas de Alineación

Los adaptadores de tubo pueden ayudar a eliminar las posiciones de alineación difíciles, al tiempo que reducen el inventario. Vea esta demostración de cómo utilizar los adaptadores a tubo Swagelok® para solucionar los problemas de alineación a la vez que se consigue un cierre estanco.

Desde 1947, Swagelok ha sido el líder en la tecnología de racores para tubo utilizada en las aplicaciones de sistemas de fluidos industriales en casi todas las industrias.

El Fundador de Swagelok Explica Su Revolucionario Racor Para Tubo

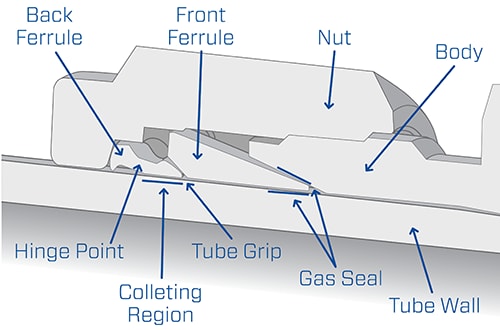

Más de 75 años después, el racor para tubo Swagelok, con su exclusiva acción de «flexión y collarín de sujeción», sigue siendo fiable para ofrecer un servicio duradero y estanco. El diseño del tipo de sujeción utiliza la acción de "flexión y collarín de sujeción" para conseguir un rendimiento óptimo en tres áreas clave:

Sujeción del Tubo

La acción de sujeción del tubo ofrece un mayor soporte axial directo/agarre mecánico.

Cierre en Servicio de Gas

La acción de pulido de la férula delantera crea zonas concentradas de contactoy contra el cuerpo del racor para conseguir un cierre más robusto.

Resistencia a las Vibraciones

El área de agarre aísla mejor los puntos de máxima tensión en el collarín de sujeción del tubo, resistiendo el doblado, la deflexión y la vibración.

Diseño del Racor para Tubo Swagelok®

Para ayudar a los instaladores a hacer conexiones de tubo más consistentes y sin fugas, este diseño de geometría avanzada con acción de flexión y collarín de sujeción es estándar en todos los racores Swagelok de acero inoxidable de 6 a 25 mm y de 1/4 a 1 pulg. En estos tamaños de racores, la férula trasera Swagelok se convierte en un elemento único en su diseño, gracias al proceso patentado de endurecimiento superficial y a la geometría de contorno avanzada patentada. Este diseño de sujeción mecánica de la férula trasera, amplía aún más el ya de por sí gran rendimiento del diseño de férula tradicional.