Swagelok® Gas Distribution Systems

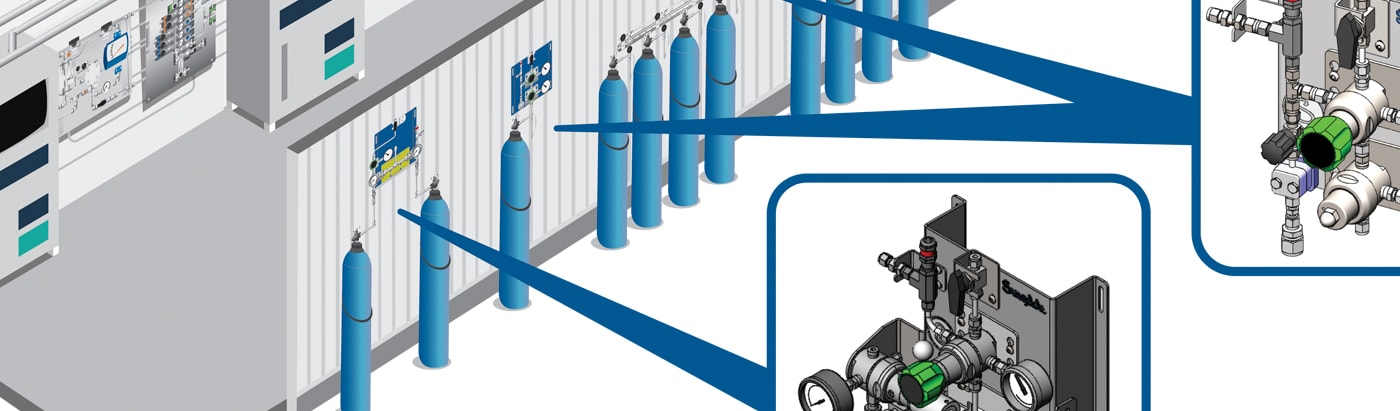

Gas distribution is a critical function for many industrial, research, and production facilities. Safely, reliably, and effectively delivering gases to where they are needed provide the foundation for a strong operation. Gas distribution systems work to deliver gases from a high-pressure source to the facility at the pressure and flow rate required by each application.

Contact a SpecialistSwagelok standard gas distribution panels come fully assembled and tested. They are easy to order from our application guide as single part numbers, minimizing the time your engineers spend on specification and procurement of new systems.

Swagelok modular panels feature minimal threaded connections to reduce potential leak points, and they are intuitively labeled to promote safe, simple use, and maintenance, and are backed by the Swagelok Limited Lifetime Warranty.

Learn more about Swagelok® Gas Distribution Systems

Swagelok gas distribution systems are built around one or a series of pressure regulation steps, and may include four subsystems:

- Swagelok® source inlet (SSI)

- Swagelok® gas panel (SGP)

- Swagelok® changeover (SCO)

- Swagelok® point-of-use (SPU)

Swagelok® Source Inlet (SSI)

The source inlet establishes a connection between the high-pressure gas source and the distribution system. It is important the inlet is built with appropriate cylinder connections, hoses, tubing, filters, and vent, purge, and relief functions to ensure that gas can be safely fed into the primary gas pressure control or automatic changeover. For a single gas cylinder, the assembly can be as simple as a hose and connector, while multiple cylinders may require a manifold incorporating many hoses and valves. Swagelok offers highly configurable options to purge or vent gases when changing bottles, always ensuring operator safety, as well as an available option to vent individual lines to maximize uptime.

Swagelok advisors will ensure all componentry is included and correctly specified with minimal connection points, hoses that do not drop to the ground, and properly supported components. Additionally, we can advise when certain gases may require the use of special hoses.

Swagelok® Gas Panel (SGP)

The SGP completes the first pressure reduction of the source gas and ensures it is delivered at the correct flow rate to the next stage of the system. Pressure reduction is accomplished in either one stage with a single pressure regulator or two stages through a dual pressure regulator arrangement.

Swagelok offers modular panels that are easy to service as any part can be detached via a Swagelok connection, so the panel never needs to be removed, as well as options implemented around the regulator and valves for color-coding if required for your site. Swagelok can also help you understand where a two-stage regulator is required.

Swagelok® Changeover (SCO)

The automatic changeover system seamlessly switches from one gas source to another to ensure an uninterrupted supply. This is accomplished through staggered set points of two pressure regulators, allowing the system to continue to operate as the primary gas source is changed. The changeover station allows for specified changeover set points to reduce wasted gas left in cylinders.

Swagelok offers more assurance the changeover point remains constant, as well as optional line regulation if your system incorporates a point of use regulator downstream—this can eliminate the additional cost of a regulator on the SCO. Swagelok specialists can help your team better understand system functionality, troubleshoot, and maintain operations.

Swagelok® Point-of-Use (SPU)

The point-of-use provides the critical last stage of pressure control prior to the gas being used. These typically have a pressure regulator, gauge, and isolation valve. Point-of-use systems offer a convenient and accurate method of adjusting pressure to meet test bench or equipment needs.

Swagelok offers standardization and consistent operation at the point-of-use; flat plate, bottom mount, top mount, and wall mount options; and a compact design. A Swagelok specialist can show you hidden savings, like how a single-stage SGP can be used to minimize cost where varying line pressure between the SGP and SPU is acceptable.

Gas Distribution Application Guides

Locate detailed information about our assemblies.

Системы подачи и распределения газов доставляют газы от источника высокого давления до установки при значениях давления и расхода, соответствующих конкретной области применения. Чаще всего они создаются на основе одной или нескольких ступеней регулирования давления и могут состоять из четырех типовых подсистем: разрядной рампы, подсистемы регулирования давления основного газа, подсистемы автоматического переключения и подсистемы места потребления. Данное руководство содержит информацию о предлагаемых компанией Swagelok системах подачи и распределения газов.

Отбор лабораторных проб — это отбор проб среды или газа в системе с целью транспортировки данных проб в лабораторию для проведения анализа. Прикладные решения Swagelok можно использовать для создания полностью документированных систем управления и отбора проб среды, а также для обеспечения целостности ваших операций.

Understanding Industrial Gas Distribution Systems

Add efficiency to your operations by learning about the design factors that most directly impact the effectiveness of industrial gas distribution systems, including how easy they are to use and maintain.

Read the White PaperSwagelok Resources Curated for You

Gas Distribution Safety and Risk Mitigation

Learn how to identify risks in gas distribution system design, installation, and maintenance—and choose the right components to ensure safe, reliable operation.

How to Reduce Your Maintenance Spend by Improving Gas Distribution

Learn how easy-to-use gas panels and an overall more efficient gas distribution and delivery system can help laboratories, refineries, and other facilities drive down maintenance costs.

Q&A: How to Reduce Costs and Improve Safety with More-Efficient Gas Distribution

Learn about common challenges that can hamper the safety and efficiency of important gas distribution systems and how a professional evaluation of those systems can provide long-term value.

Improving the Safety and Efficiency of Gas Distribution Systems

Gas distribution systems are crucial for helping labs, test centers, and industrial facilities operate at peak efficiency. Learn more about optimizing gas delivery system health and safety, reducing costs, and equipping your team for success.