Elektrische Rohrbiegevorrichtungen von Swagelok®

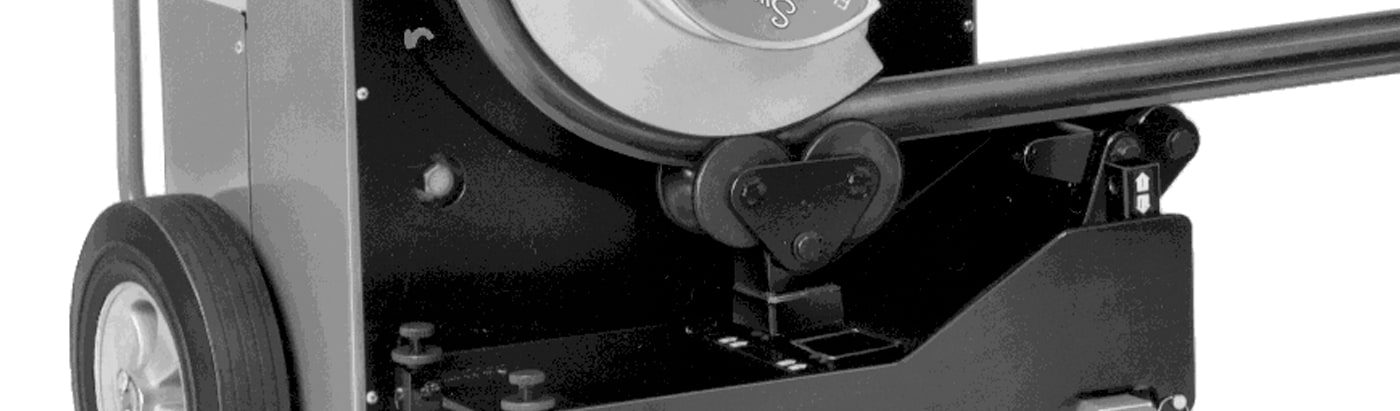

Profitieren Sie von präziser Steuerung und Effizienz mit den elektrischen Rohrbiegevorrichtungen von Swagelok. Diese benutzerfreundlichen Biegevorrichtungen wurden für Rohre mit größeren Durchmessern entwickelt und minimieren die Installationszeit und den Arbeitsaufwand. Sie reduzieren außerdem die Neigung zur Faltenbildung oder andere Schäden beim Biegen.

Hilfe bei der Auswahl von RohrbiegevorrichtungenElektrische Rohrbiegevorrichtungen von Swagelok ermöglichen präzise, qualitativ hochwertige Biegungen an Rohren, die mit Swagelok-Rohrverschraubungen in metrischen und zölligen Abmessungen kompatibel sind. Diese intuitiv zu bedienenden, elektronisch gesteuerten Biegevorrichtungen verbessern die Effizienz und Konsistenz bei der Installation von Rohren. Durch die vielseitige Auslegung werden weniger Werkzeuge benötigt und es stehen zwei Biegeführungen für eine Vielzahl von Rohrdurchmessern zur Verfügung.

Wie Rohre gebogen werden und wann gebogene Rohre von Vorteil sind

Spezifikationen

- Biegebereich von 1 bis 110°

- Für Rohrleitungen von 1 bis 2 Zoll Außendurchmesser (0,049 bis 0,220 Zoll Wanddicke) und 25 bis 50 mm Außendurchmesser (1,2 bis 5,0 mm Wanddicke)

- Eine Biegeführung für Größen von 1, 1 1/4, 1 1/2 und 2 Zoll

- Eine Biegeführung für Größen von 25, 32, 38 und 50 mm

| Maße — vertikal | 112 cm (44 Zoll) hoch, 74 cm (29 Zoll) breit, 76 cm (30 Zoll) tief |

| Gewicht | 191 kg (420 lbs) |

| Erforderliche Stromversorgung | MS-TBE-1: 115 V AC, 50/60 Hz; max. Stromaufnahme 13 A MS-TBE-2: 230 V AC 50/60 Hz; max. Stromaufnahme 7 A |

Elektrische Rohrbiegevorrichtungen—Kataloge

Hier finden Sie ausführliche Produktinformationen zu Werkstoffen, Drücken und Temperaturen, Optionen und Zubehör.

Cintreuses pour tubes électriques, d’établi et manuelles; Outils de préparation des tubes; Systèmes de support pour tubes

Arbeiten mit der Swagelok-Rohrbiegevorrichtung für die Werkbank

Verwenden Sie die Rohrbiegevorrichtung für die Werkbank von Swagelok® für präzise, wiederholbare und hochwertige Rohrbiegungen bei nahezu allen Materialien. Ganz gleich, ob Sie mit dünnwandigen Rohren mit geringem Durchmesser oder mit dickwandigen Rohren mit großem Durchmesser arbeiten—in diesem Video erhalten Sie Tipps und bewährte Verfahren rund um das Thema Rohrbiegungen.

Die Rohrbiegevorrichtung in der PraxisSwagelok-Ressourcen für Sie zusammengestellt

Grundlagenschulungen zu Fluidsystemen

Grundlagenschulungen von Swagelok® vermitteln entscheidendes Wissen über die Planung, die Auslegung, die Montage und die Instandhaltung zuverlässiger Fluidsysteme.

Fallstudie: Green Alternative Systems spart Arbeitskosten mit Rohrbiegelösungen von Swagelok

Mit Unterstützung von Swagelok ist es Green Alternative Systems (GAS) gelungen, seine Produktionszeiten um 75 % zu verkürzen und so Arbeitskosten in Höhe von 224.000 USD pro Jahr einzusparen. Erfahren Sie im Artikel mehr über diese erfolgreiche Zusammenarbeit.

Tipps für die Umsetzung komplexer Rohrsysteme

Mit diesen Tipps gelingt unter Einsatz von Handrohrbiegern die Montage komplexer, leckagedichter Rohrsysteme mit effizientem Durchfluss.

So verwenden Sie einen Handrohrbieger von Swagelok

Erfahren Sie, wie man mit einem Handrohrbieger genaue 90°- und 180°-Biegungen an einem Rohr herstellt. Die Handrohrbieger von Swagelok® liefern ein einheitliches, hochwertiges Ergebnis bei fast allen Materialien, die in Kombination mit den Verschraubungen von Swagelok eingesetzt werden.