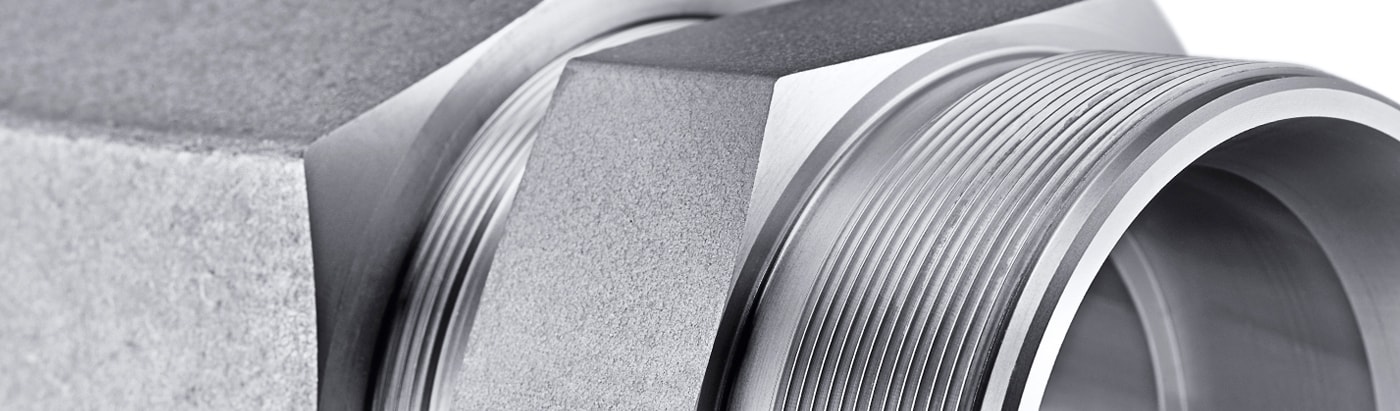

Raccords Swagelok®

Fiables, étanches et faciles à installer, les produits Swagelok ont toutes les qualités pour garantir aux opérateurs de systèmes fluides industriels une exploitation sûre, efficace et rentable des procédés et des équipements.

Afficher tous les raccordsDepuis le lancement du raccord pour tube Swagelok® en 1947, les professionnels de l’industrie s’appuient sur les raccords Swagelok pour réaliser des raccordements étanches dans des systèmes fluides conçus pour l’analyse, l’instrumentation ou des procédés utilisant des tubes de faible diamètre. Que vous ayez besoin de raccords pour des environnements corrosifs, pour des températures extrêmes ou pour des pressions élevées, nous avons des solutions pour vous aider à créer des raccordements fiables. Nous proposons une gamme complète de raccords fabriqués dans divers alliages qui sauront répondre aux besoins de nombreuses applications industrielles, y compris celles qui ont des exigences particulières.

Les raccords Swagelok respectent des normes de qualité élevées grâce à des processus extrêmement contrôlés, ce qui permet aux utilisateurs d’avoir l’esprit tranquille au moment d’intégrer ces raccords polyvalents et ultraperformants dans la conception de leurs systèmes fluides. Si vous avez besoin d’une assistance technique ou d’une formation pour tirer le meilleur parti de ces produits dans vos systèmes, quelque 200 centres de vente et de services agréés Swagelok sont présents dans le monde entier pour vous aider.

Vous cherchez des conseils pour choisir et installer des raccords ?

Категории фитингов

Трубные обжимные фитинги и переходники

- Запасные части и вспомогательное оборудование

- Защитные фильтры

- Колпаки и заглушки

- Муфты

- Муфты с малой застойной зоной

Трубные обжимные фитинги среднего давления

- Запасные части и вспомогательное оборудование

- Колпаки и заглушки

- Муфты

- С монтажной гайкой

- Соединители с внутренней резьбой

Трубные фитинги

- Запасные части и вспомогательное оборудование

- Колпаки и заглушки

- Муфтовые шаровые соединения

- Ниппели

- Переходники

Фитинги из перфторалкокси (PFA) с развальцовкой и мелкой резьбой

Пластиковые (PFA) фитинги обладают высоким пределом прочности, термической стабильностью и сопротивлением ползучести, что необходимо для работы в условиях высокой чистоты (например, производство полупроводников).

Фитинги под приварку

- Переходники под приварку

- Фитинги Micro-Fit высокой степени чистоты под приварку встык

- Фитинги под приварку враструб

- Фитинги со сварным соединением встык

Фитинги с торцевым кольцевым уплотнением VCO®

- Втулки

- Запасные части и вспомогательное оборудование

- Муфты

- С монтажной гайкой

- Соединители с внутренней резьбой

Catalogues des raccords

Trouver des informations détaillées sur nos produits – matériaux de fabrication, pressions et températures nominales, options, accessoires, etc.

The proven Swagelok® tube fitting design manufactured from corrosion-resistant alloy 2507 with NORSOK M0630 and M-650 compliance standard, NACE MR0175/ISO 15156 optional.

Предлагаются для трубок размером 1/4, 3/8, 1/2, 3/4 дюйма и 1 дюйм; Варианты исполнения гаек из перфторалкокси (PFA) и поливинилиденфторида (PVDF); Широкий выбор конфигураций

Приборные двух-, трех- и пятиклапанные блоки серий V, VB и VL; двух-, трех- и пятиклапанные блоки прямого монтажа серии VE; двухклапанные блоки выносного монтажа; модульные контрольно-измерительные системы Mod 85

FK and IPT Series Products Cone and thread or medium-pressure tube fitting connections Excellent corrosion resistance in chloride-containing environmentsManufactured to meet NORSOK and NACE® MR0175/ISO15156

От 6 до 18 мм и от 1/8 до 1 дюйма; Материалы: нержавеющая сталь 316, 316L, 316L VAR и 316L VIM-VAR; Фитинги для установки с помощью оборудования для ручной или автоматической сварки

Конструкция из нержавеющей стали, уплотнительное кольцо из фторуглерода FKM, Надежное повторяемое соединение, Предлагаются для трубок размером от 1/16 до 1 1/2 дюйма

Features: Metal components are machined from 316 stainless steel for use in rugged environments; Molded thermoplastic insulation with excellent electrical, chemical, and ultraviolet resistance and low water absorption maintains dielectric strength and integrity over a wide range of operating and climatic conditions; Gaugeable Swagelok® tube fitting or tapered pipe thread end connections (NPT/BSP) provide direct connection to tubing or piping system.

Характеристики: Безрезьбовой и бесшовный переход от фланцев толстостенных трубопроводов к тонкостенным трубопроводам. Типы фланцев соответствуют стандартам ASME, DIN, EN и JIS. Цельнокованый корпус с полной обработкой. Предлагаются с торцевыми трубными обжимными фитингами Swagelok® до 50 мм и до 2 дюймов.

Swagelok® tube fittings and tube adapters reduce the risk of costly system downtime with reliable tubing connections and are available in a variety of sizes and materials.

Размеры от 1/16 до 1 дюйма; Изготавливаются из нержавеющей стали марки 316, латуни и углеродистой сталиl; Резьбы NPT, ISO/BSP и SAE

Размеры от 6 до 18 мм и от 1/16 до 1 дюйма; Нержавеющие стали высокой степени чистоты; Оригинальная конструкция, подлинная марка VCR

Характеристики: конструкция из нержавеющей стали 316; температура до 1000 °F (537 °C); фитинги среднего давления, диаметр от 1/4 до 1 дюйма, номинальное давление до 20 000 фунтов на кв. дюйм, ман. (1378 бар); фитинги высокого давления, диаметр от 1/4 до 9/16 дюйма, номинальное давление до 60 000 фунтов на кв. дюйм, ман. (4134 бар); предлагаются варианты исполнения, соответствующие стандарту NACE® MR0175 / ISO15156

Температура от 20 до 204 °C (от 70 до 400 ºF); Рабочее давление до 18,9 бара (275 фунтов на кв. дюйм, ман.); Размеры от 1/8 до 1/2 дюйма

Характеристики: пригодны для жидкостной и газовой хроматографии; конструкция из нержавеющей стали 316; предлагаются размеры от 1/16 до 1/2 дюйма.

Размеры циферблата 40, 50, 63, 100, 115 и 160 мм (1 1/2, 2, 2 1/2, 4, 4 1/2 и 6 дюймов); Точность в соответствии со стандартами ASME, EN и JIS; Поставляются с различными торцевыми соединениями, в том числе с трубными переходниками Swagelok®; Конфигурации с креплением позади корпуса по центру, позади внизу и снизу; Конструкция из нержавеющей стали и армированного термопласта; Предлагаются варианты исполнения с жидкостным наполнением и без наполнения

Размер от 1/8 до 1 дюйма, Нержавеющая сталь марки 316 или 316L, Торцевые соединения под трубку с резьбами NPT, SAE и сварные соединения

Les avantages du raccord pour tube Swagelok®

Avec une conception qui a fait ses preuves et une fabrication précise à partir de matières premières de qualité supérieure, les raccords pour tubes Swagelok sauront répondre à vos plus hautes attentes en matière de sécurité et de fiabilité.

Découvrir les avantagesLes ressources de Swagelok sélectionnées pour vous

Introduction aux raccords : déterminer le diamètre et le pas d’un filetage

Même les professionnels les plus aguerris peuvent avoir des difficultés à déterminer un filetage. Andy Hitchcock, responsable produit chez Swagelok, explique comment déterminer le diamètre et le pas des filetages de vos raccords à l’aide d’un pied à coulisse, d’un peigne à filet et d’un guide de détermination des filetages.

Une sécurité et une fiabilité accrues pour Shenyang Blower Works Group

Découvrez comment Swagelok Shanghai a aidé Shenyang Blower Works Group Corporation à faire faire des économies à ses clients grâce à des équipements plus fiables, tout en améliorant la sécurité de ses installations et le rendement de sa production.

Installation des raccords pour tubes Swagelok

Cette vidéo montre toutes les étapes de l’installation des raccords pour tubes Swagelok – des raccords qui ont acquis dans le monde entier une réputation de qualité et de fiabilité sur la durée.

Raccords Swagelok

Lorsque les entreprises les plus réputées au monde veulent des raccordements qui durent, elles se tournent vers Swagelok. Étanchéité, facilité d’installation, disponibilité, services d’assistance – nos raccords pour tubes sont la référence en la matière. Nos raccords en acier inoxydable double bagues ont acquis dans le monde entier une réputation de qualité et de fiabilité sur la durée. Cette réputation est le fruit des efforts que nous déployons pour améliorer continuellement nos produits ainsi que des performances de nos raccords dans des milliers d’applications les plus diverses.