Swagelok®コーン&スレッド継手

Swagelok®コーン&スレッド継手 IPTシリーズは、さまざまな合金から製造されており、各種最終用途の環境、および中圧/高圧アプリケーション(最高使用圧力:413.4 MPa)において、信頼性の高いパフォーマンスを発揮します。

コーン&スレッド継手を見るコーン&スレッド(C&T)継手による接続は、中圧/高圧下で信頼性の高いパフォーマンスを発揮するものとして、長きにわたって採用されてきました。Swagelokコーン&スレッド継手IPTシリーズの材質は316ステンレス鋼、合金625、合金2507から選ぶことができ、サイズは1/4~1 1/2 インチ、最高使用温度は371°Cです。

Swagelokコーン&スレッド継手 IPTシリーズはNACE MR0175/ISO 15156に準拠しており、耐振接続部品として使用することができます。すべての圧力接続部にウィープ・ホールが標準で付いているため、適切に接続されているかを容易に確認することができます。めす中高圧用C&T継手、アダプター、カップリングには、グランドおよびカラーが付属しています(特に記載がない限り)。

コーン&スレッド継手に関して質問がありますか?

콘 & 쓰레드 피팅 카테고리

コーン&スレッド継手のカタログ

構成部品とその材質、使用圧力、使用温度、オプション、アクセサリーなど、製品に関する詳細情報につきましては、以下の資料をご参照ください。

특징: 316 스텐레스강 구조; 537°C (1000°F)까지의 온도; 중압 (MP) 피팅, 크기—1/4 ~ 1 in., 압력 등급—최대 20 000 psig (1378 bar); 고압 (HP) 피팅, 크기—1/4 ~ 9/16 in., 압력 등급—최대 60 000 psig (4134 bar); NACE® MR0175/ISO15156 적합

関連資料/コラム記事

The Anatomy of a Hydrogen Fitting

Learn why fittings designed specifically for hydrogen applications can help fuel cell vehicle OEMs and infrastructure developers achieve safer and more reliable fuel systems.

압축 피팅으로 중압 오일 및 가스 애플리케이션 최적화하기

오일 및 가스 상부설비(topside asset)의 중압 애플리케이션에서, 기존 콘 & 쓰레드 연결구에 비해 압착 피팅이 어떻게 설치 속도와 성능 면에서 이점을 제공할 수 있는지 알아보십시오.

수소 연료전지 자동차의 구성부품 선정 최적화

수소 운송 수단은 신뢰할 수 있는 부품 사양과 그 선정 여부에 따라 크게 달라집니다. 적합한 부품을 찾으려면 무엇이 필요한지 자세히 알아보십시오.

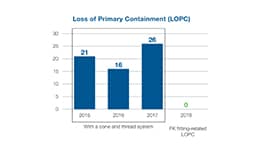

사례 연구: 해양 석유개발 운영업체

한 해양 오일 플랫폼 운영업체가 어떻게 콘 & 쓰레드에서 FK 시리즈 피팅으로 전환하여 설치 시간을 80%까지 절감할 수 있었는지 알아보십시오.