Swagelok®メカニカル・シール・サポート・システム

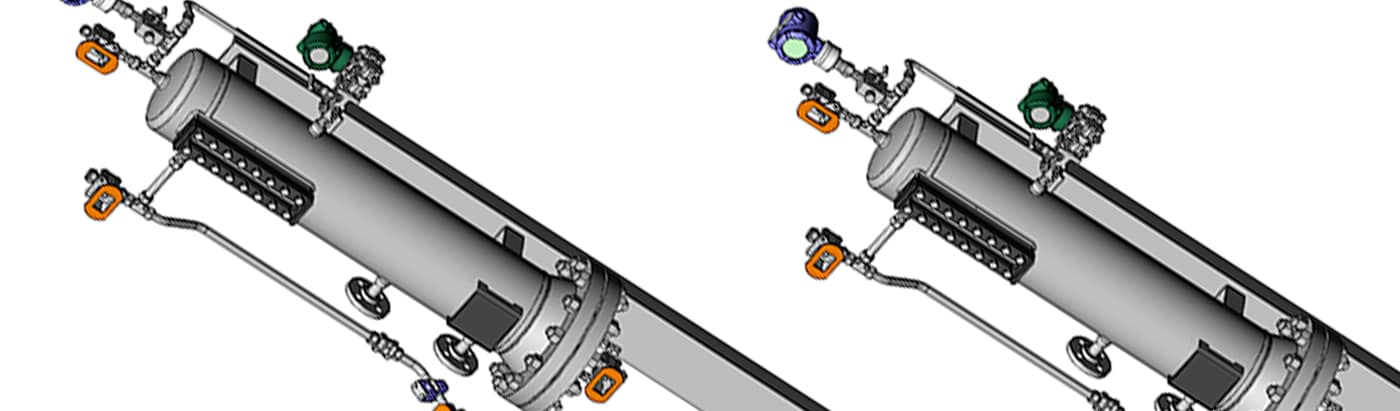

スウェージロックは、専門スタッフが設計し、設定が容易でメンテナンスが可能なシール・サポート・システムを提供しています。Swagelokメカニカル・シール・サポート・キットは、回転機のオンライン化や効率的なオペレーションの維持に適しており、ダウンタイム(提示時間)を最小限に抑え、コストや時間を削減しながら、安全なオペレーションを実現します。

適切なシステムの選定について問い合わせるスウェージロックのメカニカル・シール・サポート・キットおよびアセンブリーはAPI 682規格に適合しており、信頼性が高く、取り付けが容易なシステムです。管用ねじの使用をやめることで、接続部を減らし 、漏れを最小限に抑えます。大気側プラン および シール流体側プラン のキットにはすべての部品および図面が含まれているため、APIガイドラインに従って簡単に取り付けることができます。キットには、チューブを曲げて漏れを防止する方法も示されています。

スウェージロックは、パネルやシール・ポットなど、特定のアプリケーションに合わせたカスタマイズ可能なシール・プラン・アセンブリーを提供しています。ビトウィーン・シール・プラン およびシール流体側プランのアセンブリーは単品、または取り付けキットと併せて注文することが可能です。信頼性の高いスウェージロックのシステムは、空気のたまりを防止するハイ・ポイント・ベント、安全なパージが可能なロー・ポイント・ドレン、トラブルシューティング用の圧力/温度測定ポイントを備えています。アクセスしやすいフィルター、ストレーナー、バイパス・ループにより適切な流量を確保しているほか、カスタマイズ可能な設計により、API規格に準拠したブロック/ブリード・バルブや2バルブ・マニホールドで安全性を高めています。

仕様

| シール・プラン・キット(SPK) | シール流体側プラン:API 11、API 12、API 13、API 14、API 21、API 22、API 23、API 31、API 41 大気側プラン:51、62、65A、65B |

| シール・プラン・アセンブリー(SPA) | シール流体側プラン:API 32 ビトウィーン・シール・プラン:API 52、API 53A、API 53B、API 53C、API 54、API 55、API 72、API 74、API 75、API 76、API 72/76 |

| 最高使用圧力 | 4.96 MPa |

| シール接続サイズ | 3/8~3/4 インチ・サイズNPTねじ |

| シール接続タイプ | めす/おすコネクター、延長型おすコネクターでさまざまなアプリケーションに対応 |

| チューブ外径サイズ | 1/4~1 インチ、6~25 mm |

アプリケーション・ガイドを見る

アセンブリーに関する詳細情報につきましては、以下の資料をご参照ください。

Seal Support Systems are each designed for a specific mechanical seal and set of process conditions. These systems supply either a gas or a liquid to the mechanical seal to regulate the environment in which the seal operates, protecting rotating equipment from damage. Swagelok seal support systems rely on the guidance provided by API 682: Pumps - Shaft Sealing Systems for Centrifugal and Rotary Pumps.

カスタム加工(すべての業界向け)

スウェージロックのトレーニングを受けた専門スタッフが、お客さまの手間を省き、流体システムのパフォーマンスを改善するべく、お客さまに合わせたシステムを設計し、組み立てを行います。

必要なサポートを探す関連資料/コラム記事

API 682とお客さま:優れたメカニカル・シール・サポート・システムを構築する

今回は、API 682によるメカニカル・シール・サポート・システムの設計および取り付けに関するガイドライン、ならびに、ベスト・プラクティスを適用することで、システムの耐用年数を延ばし、作業性を向上させる方法を紹介します。

スポットライト:メカニカル・シール・サポート・システム・ソリューション

API 682に準拠したSwagelok®メカニカル・シール・サポート・システムは、API 682のベスト・プラクティスを取り入れつつ、さらに進化させて、システムの取り付けやメンテナンスを容易にする設計原理を採用しています。

人手不足を緩和する流体システム製造

プラントにおける安定的なオペレーションは、さまざまな流体システムによって支えられています。人材が不足している場合、製造を外部委託することで状況を大きく改善できるかもしれません。

フィールド・エンジニアリングとは?:流体/サンプリング・システムのパフォーマンス改善のために

スウェージロックのフィールド・エンジニアは、漏れやサンプル精度の低下など、流体/サンプリング・システムの担当者が抱えるあらゆる問題の解決をサポートします。今回は、フィールド・エンジニアリング・サービスに関するさまざまな質問にスウェージロックの流体システム専門スタッフが答えます。