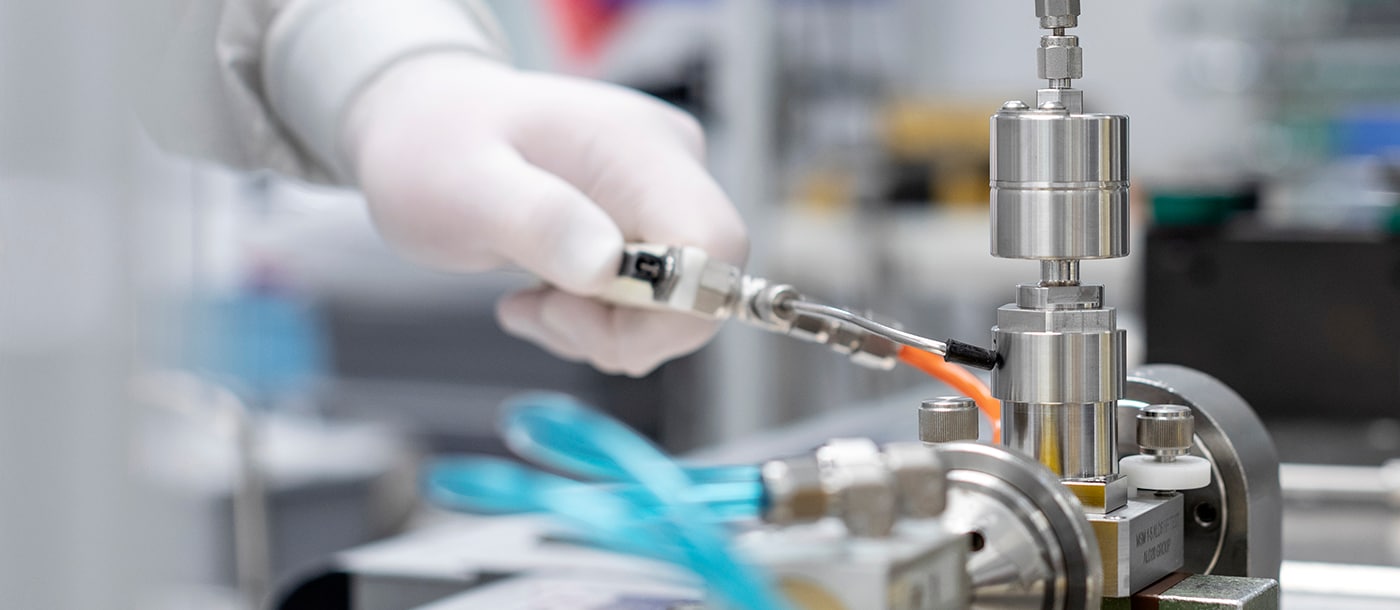

Swagelok® Ultrahochreine Ventile für die Atomlagenabscheidung mit hohem Durchfluss (Serie ALD20)

Die ultrahochreinen ALD20-Ventile von Swagelok zeichnen sich durch eine hohe Durchflusskapazität aus und eignen sich damit hervorragend für Atomlagenabscheidungsprozesse, für die Vorstufengase mit niedrigem Dampfdruck erforderlich sind.

Informationen zu ALD20-Ventilen anfordernDas für ultrahochreine Anwendungen konzipierte ALD20-Ventil für hohe Durchflussraten von Swagelok® bietet die gewohnte Zuverlässigkeit und Leistung wie alle Swagelok®-ALD-Ventile, sowie eine einzigartiger Temperaturstabilität. Die Verwendung des Ventils ermöglicht es Herstellern, ohne viel Änderungsaufwand mit verschiedenen Verfahren und Chemikalien mit niedrigem Dampfdruck zu experimentieren, um eine gleichmäßige Gasabscheidung zu erzielen, die für die Entwicklung fortschrittlicher Technologien erforderlich ist.

Vorteile des Swagelok-ALD20-Ventils:

- Mit einer Durchflusskapazität von 1,2 Cv und der gleichen Baugröße von 1,5 Zoll wie die bestehenden ALD-Ventile bietet das Ventil eine verbesserte Leistung—ganz ohne Umrüstung.

- In einer etwas größeren Standardausführung (1,75 Zoll) bietet das Ventil mit 1,7 Cv—die höchste Durchflusskapazität von allen auf dem Markt verfügbaren Ventilen für ultrahochreine Anwendungen.

- Das Ventil kann in eine Gaskammer mit einem Temperaturbereich von 10 °C (50 °F) bis 200 °C (392 °F) eingetaucht werden, so dass der Stellantrieb während des Aufheizens nicht abgetrennt werden muss und die Konsistenz der Abscheidung verbessert wird.

- Aus Edelstahl 316L VIM-VAR oder Alloy 22 gefertigt weist das Ventil eine verbesserte Korrosionsbeständigkeit auf.

- Dank des hochpolierten Faltenbalgs mit einer Oberflächenrauheit (Ra) von 0,127 µm unterstützt der Einsatz dieses Ventils Ihre Prozessintegrität durch einen sauberen Betrieb über eine sehr lange Lebensdauer hinweg.

- Das Ventil zeichnet sich durch schnelle (<10 ms) und wiederholbare Betätigungen für einen gleichmäßigen Durchfluss und eine präzise Dosierung aus.

Kundenspezifische Durchflusskoeffizienten sind ebenfalls erhältlich.

Erfahren Sie, wie der Einsatz des ALD20-Ventils bestehende Probleme in der Halbleiterfertigung löst

ALD20-Ventile—Spezifikationen

| Betriebsdruck | Vakuum bis 1,4 bar (20 psig) |

| Berstdruck | >220 bar (3.200 psig) |

| Betätigungsdruck | 4,9 bis 6,2 bar (70 bis 90 psig) |

| Temperatur | 10 ° bis 200 °C (50 ° bis 392 °F) |

| Durchflusskoeffizient (Cv) | 1,2 (modulare Flächenmontage) oder 1,7 (Durchgangsbauform) |

| Körperwerkstoffe | Edelstahl 316L VIM-VAR oder Alloy 22 |

| Faltenbalgwerkstoff | Alloy 22 (0,127 Ra Oberflächenrauheit) |

| Endanschlüsse | Typ (Größe): VCR®-Innnengwinde (1/2 Zoll), drehbares VCR-Außengewinde (1/2 Zoll), Stumpfschweißfitting, 0,5 Zoll lang (1/2 Zoll x 0,049 Zoll), modulare Flächenmontage mit C-Dichtung für hohen Durchfluss (1,5 Zoll) |

Sie benötigen Hilfe bei der Wahl der richtigen ALD-Ventile?

Ventile der Serie ALD20—Kataloge

Hier finden Sie ausführliche Produktinformationen zu Werkstoffen, Druckstufen, Auslegungstemperaturen, Optionen und Zubehör.

Характеристики: Сверхвысокий циклический срок службы с высокой скоростью срабатывания; Cv в диапазоне от 0,27 до 0,62; возможность работы при температуре до 392 °F (200 °C) с термостойкими приводами; вариант исполнения с электронным датчиком положения привода; подходят для применения в сверхчистых системах с корпусом из нержавеющей стали 316L VIM-VAR; торцевые соединения VCR®, под приварку встык и модульные торцевые соединения для монтажа на поверхность.

Kleines Ventil mit großer Wirkung: Warum ein neues Ventil die Halbleiterproduktion verändern könnte

Erfahren Sie mehr darüber, wie die neueste Innovation in der ALD-Ventiltechnologie neue Möglichkeiten für Hersteller modernster Halbleiter schafft.

Neue Elemente aus dem Periodensystem in der Halbleiterfertigung nutzenSwagelok-Ressourcen für Sie zusammengestellt

Verbessern Sie Ihre Halbleiterproduktion durch den Einsatz optimierter Legierungen

Erfahren Sie, wie Halbleiterhersteller ihre Produktionsausbeute und Profitabilität durch Auswahl der passenden Werkstoffe für wichtige Fluidsystemkomponenten langfristig optimieren.

Q&A: Entwicklungen und Trends in der Halbleiterherstellung

In diesem Artikel beschäftigen wir uns damit, wie die Zusammenarbeit zwischen Herstellern von Halbleiter-Fertigungsanlagen, Chipproduzenten und Fluidsystemanbietern in der Halbleiterindustrie über Jahrzehnte hinweg dazu beigetragen hat, dass das Mooresche Gesetz eingehalten werden konnte. Zudem werfen wir einen Blick in die Zukunft dieser schnelllebigen Branche.

Hersteller für Glasfaserproduktionssysteme erhöht seine Effizienz durch maßgeschneiderte Lösungen für seine Kunden

Bereits seit den 1980er-Jahren setzt Rosendahl Nextrom auf die Zusammenarbeit mit Swagelok, um sich geschäftlich weiterzuentwickeln. Erfahren Sie mehr über die Lösungen, mit denen es der Firma gelungen ist, der Konkurrenz stets einen Schritt voraus zu sein und sich als Marktführer zu behaupten.

Zuverlässige Fluidsystemlösungen für die Wissenschaft

Erfahren Sie mehr darüber, warum sich das finnische Unternehmen Bluefors bei der Herstellung seiner Mischungskryostate für Anwendungen in den Bereichen Quantum-Computing und Experimentalphysik auf die Fluidsystemkomponenten und -lösungen von Swagelok verlässt.