Flexible thermoplastique Swagelok®

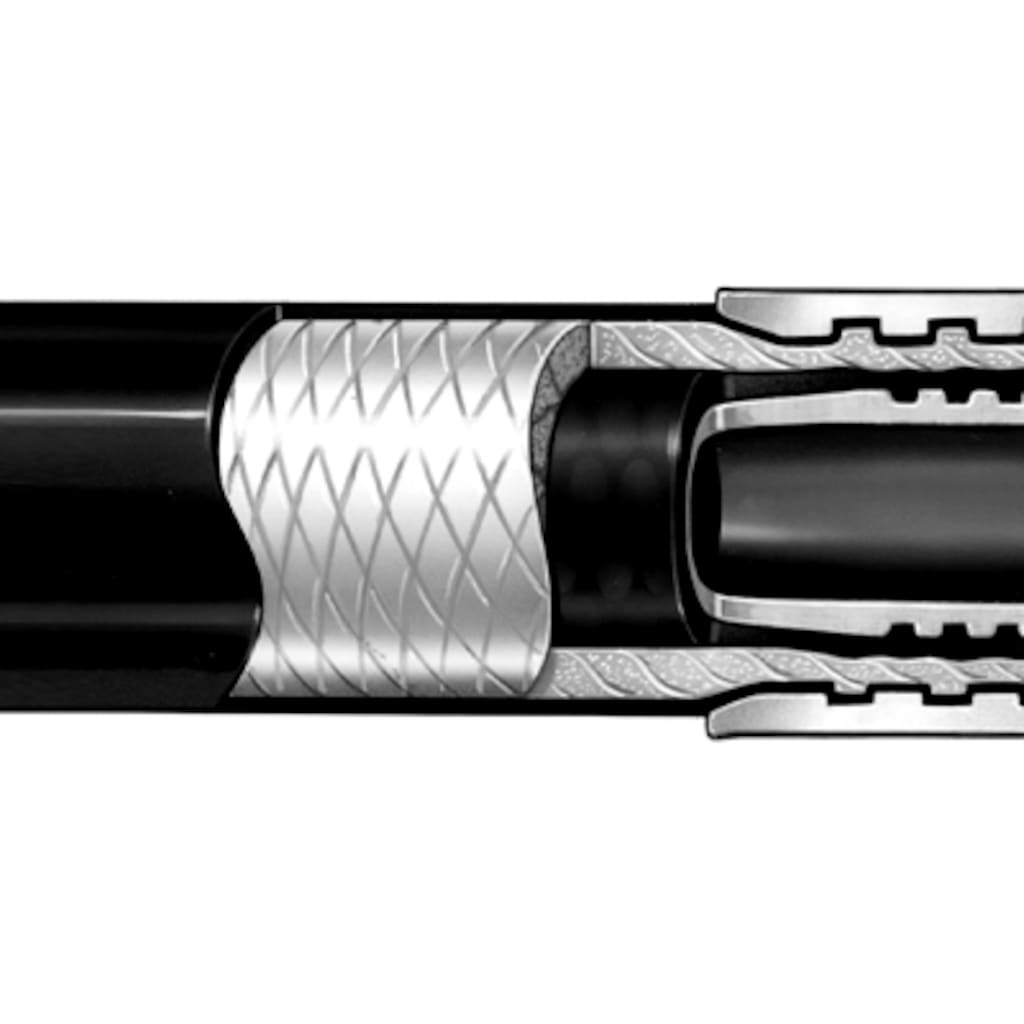

Conçus pour résister à des pressions d’impulsion élevées et à des mouvements dynamiques, les flexibles thermoplastiques Swagelok® (avec tube central en nylon ou en polyéthylène) sont des flexibles robustes et performants dans des applications hydrauliques et dans les systèmes de ravitaillement en carburant des véhicules fonctionnant au gaz naturel comprimé (GNC).

Voir des flexibles thermoplastiquesLes flexibles thermoplastiques Swagelok conçus pour résister aux impulsions de pression lorsqu’ils sont utilisés avec des pompes hydrauliques et des vannes à boisseau sphérique. Parce qu’ils résistent aux pressions élevées fluctuantes, ces flexibles sont particulièrement efficaces dans les systèmes de ravitaillement en carburant des véhicules fonctionnant au GNC. Ils sont d’ailleurs disponibles avec des certifications NGV et ECE R110 pour un usage avec des carburants de substitution.

Notre flexible en nylon polyvalent et performant peut être installé rapidement et en toute sécurité avec divers raccords dans des systèmes hydrauliques, des systèmes qui mettent en œuvre du gaz naturel et d’autres applications générales. Sa paroi lisse permet de contrôler le débit avec précision et de nettoyer soigneusement l’intérieur du flexible, tandis que son enveloppe en polyuréthane résiste à l’abrasion.

Le polyéthylène du tube central est conforme à la réglementation FDA 21 CFR section 177 1520 et NSF-51, concernant les utilisations avec des aliments, des produits laitiers ou de l’eau. Les couches de renfort internes en fibre tressée améliorent la tenue en pression et la souplesse du flexible. L’enveloppe en polyuréthane résiste à l’abrasion et empêche la rétention d’humidité et la contamination du système.

Besoin d’aide pour choisir un flexible thermoplastique ?

Thermoplastic Hose Categories

End Connections

Enable easy field installation of Swagelok® hoses by selecting from a variety of end connections in a range of sizes.

Nylon Hose

Use the 7R and 8R Series nylon hose in hydraulic applications where outgassing is a concern.

Polyethylene Core Hose

Ensure FDA compliance and prevent system contamination in food, dairy, and water applications with Swagelok's polyethylene core hose.

Catalogues des flexibles et tubes souples

Trouver des informations détaillées sur nos produits – matériaux de fabrication, pressions et températures nominales, options, accessoires, etc.

Swagelok® hose and tubing products are available in custom lengths, in diameters 2 inches and under, and with many types of end connections, core materials, and reinforcement styles to suit a broad spectrum of pressures and temperatures.

Services de conseil concernant les flexibles Swagelok®

Découvrez comment améliorer vos procédures de sélection, d’installation, d’inspection et de maintenance des flexibles afin d’en améliorer la durée de vie et les performances et de réduire vos coûts par la même occasion.

En savoir plus sur la gestion des flexiblesDes ressources Swagelok sélectionnées pour vous

Des flexibles sûrs et des installations moins onéreuses en 3 étapes

Lors des opérations régulières de maintenance des installations, la sécurité des flexibles industriels est souvent négligée. Il est pourtant important de leur accorder la plus grande attention. Les fuites et l’usure de ces composants peuvent nuire au bon fonctionnement de vos installations. Découvrez des conseils pour éviter des situations dangereuses et diminuer vos coûts d’exploitation.

Comment un plan d’entretien des flexibles industriels pourrait faire économiser des milliers d’euros à votre usine

Savoir quand remplacer des flexibles industriels peut vous éviter des dépenses de maintenance de plusieurs milliers d’euros. Découvrez comment évaluer vos systèmes et élaborer un plan de maintenance préventive pour gérer la durée de vie des flexibles.

Remplacement des flexibles industriels : considérations relatives au matériau du tube central

Lorsque vous choisissez un flexible industriel, pensez d’abord au tube central, c’est-à-dire à la couche située le plus à l’intérieur dans un flexible. Découvrez comment choisir le flexible idéal pour votre application grâce aux conseils d’experts de Swagelok sur le matériau et la structure de la paroi du tube central.

Comment bien choisir la couche de renfort d’un flexible

Les flexibles industriels comportent généralement des couches de renfort essentielles, qui contribuent à la longévité et aux performances de ces produits. Découvrez ces différents types de renforts et ceux qui conviennent le mieux aux différentes applications des systèmes fluides.