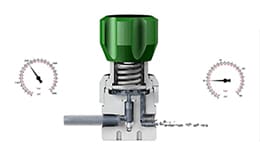

世伟洛克罐封调压阀对于确保在含有危险流体的储罐周围地操作人员和旁观者的安全至关重要。它们能在蒸汽空间中保持一致的惰性气体压力水平,防止危险蒸汽泄漏。

罐封调压阀可降低与压力密封罐相关的安全风险。

- TBRS 系列调压阀允许气体进入罐体以保持恒压,防止抽气时罐体坍塌

- TBVS 系列背压调压阀将余压排放到蒸汽回收系统,防止意外排放

这些调压阀可在罐封应用中提供精确的压力控制。其特点包括:设定压力弹簧上的细螺距螺纹可提高可调节性;高灵敏度的隔膜感应机构可实现精确的压力检测;外部反馈回路可提高调压阀的性能。此外,这些调压阀还采用 316L 不锈钢制造反馈管、调压阀本体和提升阀芯套筒等组件,能够经受恶劣环境的考验,确保耐腐蚀性和长期耐用性。

规格

| 材料 | 316L 不锈钢结构 |

| 端接尺寸 | 1/2、1 和 2 in. |

| 工作压力 | 最高 232 psig (16.0 bar) |

| 压力控制范围 | 0.07 至 0.14 psig(2.0 至 4.0 in. H2O,5 至 10 mbar)到 0.72 至 11.6 psig(20 至 321 in. H2O,50 至 800 mbar) |

| 流量系数 (Cv) | 0.20、0.30、1.00 |

| 温度 | –4 至 212°F(–20 至 100°C) |

罐封调压阀样本

查找有关我们的罐封调压阀的全面详细信息,包括结构材料、配件、压力和额定温度。

Swagelok offers pressure-reducing and vapor recovery (back-pressure) tank blanketing regulators for systems requiring an inert gas in the vapor space of a storage tank.

Need Help Selecting the Right Regulators?

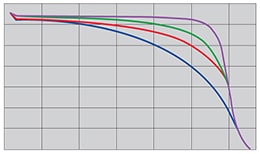

Evaluate the performance of various vaporizing regulators across diverse applications conditions using our Regulator Flow Curve Generator tool.

Find the Right RegulatorSwagelok Regulator Resources

Managing Supply Pressure Effect (SPE) in a Regulator

Supply pressure effect, also known as dependency, is an inverse relationship between inlet and outlet pressure variables within a regulator. Learn how to manage this phenomenon in your pressure regulators with tips from Swagelok.

How Thorough Testing Ensures Reliable Regulator Performance

Have you ever wondered what testing goes into a product designed to operate in extreme conditions? Take a look behind the lab doors, following the development journey of RHPS Series industrial regulators rated for use at temperatures well below zero.

How to Flatten a Regulator Flow Curve to Reduce Droop

Droop is an issue for every pressure-reducing regulator. Learn how to minimize droop and flatten regulator flow curves with various dome loaded regulator configurations.

How to Use a Regulator to Reduce Time Delay in an Analytical Instrumentation System

Time delay is often underestimated or misunderstood in analytical systems. One way to mitigate this delay is with a pressure-controlled regulator. Learn how to manage your analytical system’s time delay with these tips.