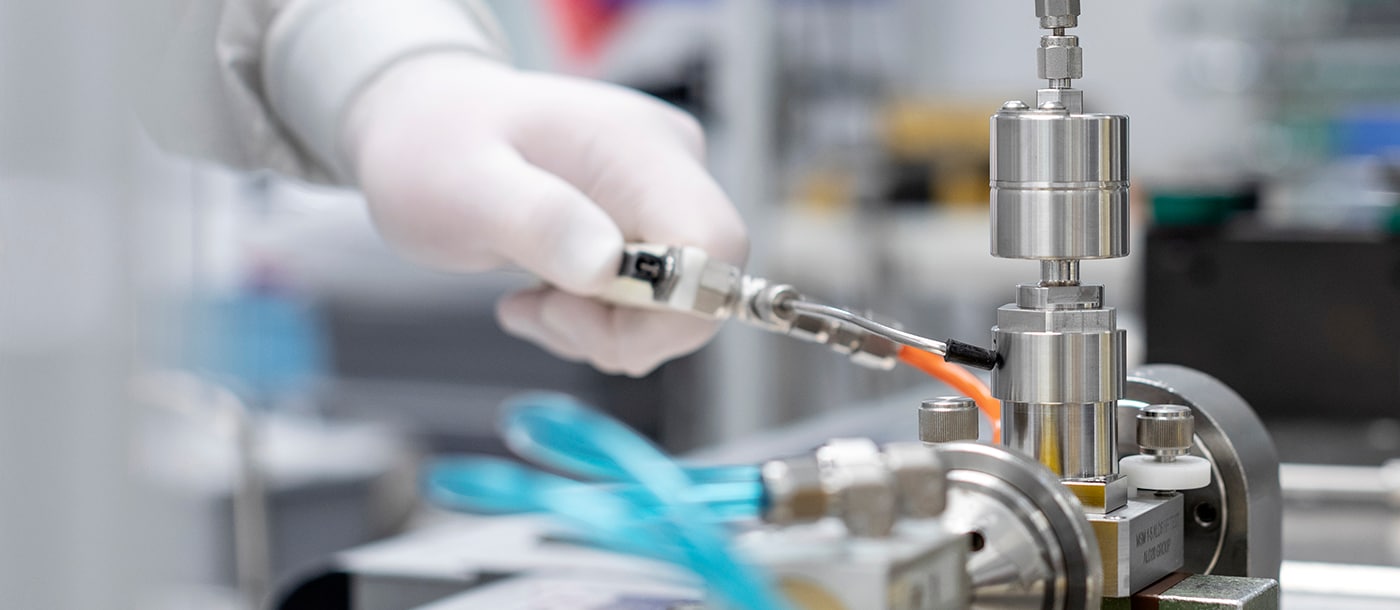

Swagelok®超高純度用バルブ(大流量原子層蒸着プロセス・アプリケーション用)(ALD20シリーズ)

Swagelok超高純度用バルブ ALD20シリーズは、低蒸発圧プリカーサー・ガスを必要とする原子層蒸着プロセスに適した大流量用バルブです。

ALD20シリーズ・バルブについて問い合わせるSwagelok®超高純度用バルブ(大流量用) ALD20シリーズは、ALDバルブに求められている信頼性および性能を維持しつつ、かつては対応が難しかった温度の安定性および流量も達成しています。このため、メーカーは大幅な工程変更を行うことなく、最先端技術の開発に欠かせない均一な蒸着を実現するため、さまざまな工程と低い蒸気圧の組み合わせを試すことができます。

Swagelok ALD20シリーズ・バルブの特徴:

- 1.2の流量係数(Cv値)を実現しながら、フットプリントは既存のALDバルブと同じ1.5 インチ・サイズのため、既存装置を改造することなくパフォーマンスの改善を実現します。

- フットプリントが1.75 インチ・サイズの標準ALD20バルブは、流量係数(Cv値)が1.7とさらに増えています。これは現在サイクル・ライフに優れた超高純度用バルブの中では最高の値です。

- アクチュエーター部分を含めバルブ全体をガス・ボックスに入れて使用することができます(使用温度範囲:10~200°C)。加熱中にアクチュエーターを隔離する必要がなく、蒸着の安定性が向上します。

- バルブ・ボディの材質に316L VIM-VARステンレス鋼または合金22を採用しており、耐食性に優れています。

- 高度な研磨を施したベローズ(表面粗さ:0.13 μm仕上げ)は、超高サイクル・ライフにおいてもクリーンなオペレーションを支え、プロセスの完全性を維持します。

- エアー・アクチュエーターは高速(<10 ms)で繰り返し作動し、正確かつ一貫した流量を実現し、供給要件を満たします。

流量係数(Cv値)のカスタム設定も可能です。

仕様

| 使用圧力範囲 | 真空~0.14 MPa |

| 破裂時 | >22.0 MPa |

| 操作時 | 0.49~0.62 MPa |

| 使用温度範囲 | 10~200°C |

| 流量係数(Cv値) | 1.2(集積モデル) または1.7(ストレート型) |

| ボディ材質 | 316L VIM-VARステンレス鋼または合金22 |

| ベローズ材質 | 合金22(表面粗さ:0.13 μm仕上げ) |

| エンド・コネクション・タイプ(サイズ) | めすVCR®面シール継手(1/2 インチ)、回転可能型おすVCR継手(1/2 インチ)、チューブ突き合わせ溶接、長さ:12.7 mm(1/2 インチ X 肉厚1.24 mm)、集積モデル大流量用Cシール(1.5 インチ) |

ALDバルブの選定に関して質問がありますか?

ALD20シリーズ・バルブのカタログ

構成部品とその材質、使用圧力、使用温度、オプション、アクセサリーなど、製品に関する詳細情報につきましては、以下の資料をご参照ください。

원자층 증착 (ALD) 용 다이어프램 밸브 고속 개폐 시에도 매우 긴 수명 유지 ; Cv 범위 0.27 ~ 0.62; 고온용 개폐기로 200°C (392°F)까지 사용가능; 전자 개폐기 위치 감지 옵션; 초고순도 사양에 적합한 316L VIM-VAR 스텐레스강 몸체; VCR®, 튜브 맞대기 용접 및 블럭 조립식 연결구

関連資料/コラム記事

最適な合金で半導体製造の歩留まりを高める

今回は、重要な流体システム部品に適した金属材料を選定することで、エンドからエンドまでの製造の歩留まりを高め、長期的な収益性の向上を図る方法を紹介します。

Q&A:半導体製造の過去・現在・将来

半導体装置メーカー、マイクロデバイス・メーカー、流体システム・ソリューションのプロバイダーが連携することで、数十年間にわたっていかにして半導体市場はムーアの法則の要求に追いつくことができたのでしょうか。これからの展望と併せて紹介します。

光ファイバー装置メーカー、カスタマイズされたソリューションで効率アップを実現

ローゼンダール・ネクストロム社は、1980年代からスウェージロックのサポートを受けて、ビジネスを推進してきました。競合他社とは一線を画し、業界のトップを走り続けるローゼンダール・ネクストロム社のソリューション事例を紹介します。

最先端科学で信頼できる流体システム・ソリューション

フィンランドの希釈冷凍機メーカーであるブルーフォース社が、量子コンピューターや実験物理学などに欠かせない流体システム部品やソリューションに関して、スウェージロックに信頼を寄せている理由を紹介します。