Swagelok®超高純度用バルブ(大流量原子層蒸着プロセス・アプリケーション用)(ALD20シリーズ)

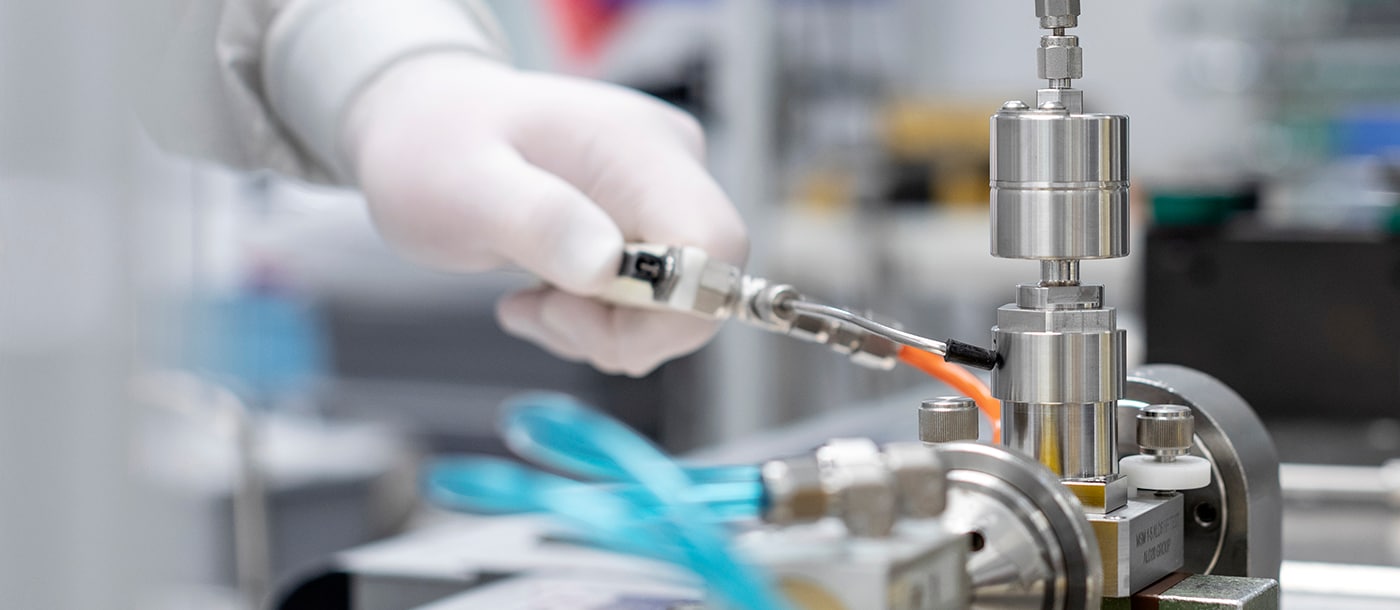

Swagelok超高純度用バルブ ALD20シリーズは、低蒸発圧プリカーサー・ガスを必要とする原子層蒸着プロセスに適した大流量用バルブです。

ALD20シリーズ・バルブについて問い合わせるSwagelok®超高純度用バルブ(大流量用) ALD20シリーズは、ALDバルブに求められている信頼性および性能を維持しつつ、かつては対応が難しかった温度の安定性および流量も達成しています。このため、メーカーは大幅な工程変更を行うことなく、最先端技術の開発に欠かせない均一な蒸着を実現するため、さまざまな工程と低い蒸気圧の組み合わせを試すことができます。

Swagelok ALD20シリーズ・バルブの特徴:

- 1.2の流量係数(Cv値)を実現しながら、フットプリントは既存のALDバルブと同じ1.5 インチ・サイズのため、既存装置を改造することなくパフォーマンスの改善を実現します。

- フットプリントが1.75 インチ・サイズの標準ALD20バルブは、流量係数(Cv値)が1.7とさらに増えています。これは現在サイクル・ライフに優れた超高純度用バルブの中では最高の値です。

- アクチュエーター部分を含めバルブ全体をガス・ボックスに入れて使用することができます(使用温度範囲:10~200°C)。加熱中にアクチュエーターを隔離する必要がなく、蒸着の安定性が向上します。

- バルブ・ボディの材質に316L VIM-VARステンレス鋼または合金22を採用しており、耐食性に優れています。

- 高度な研磨を施したベローズ(表面粗さ:0.13 μm仕上げ)は、超高サイクル・ライフにおいてもクリーンなオペレーションを支え、プロセスの完全性を維持します。

- エアー・アクチュエーターは高速(<10 ms)で繰り返し作動し、正確かつ一貫した流量を実現し、供給要件を満たします。

流量係数(Cv値)のカスタム設定も可能です。

仕様

| 使用圧力範囲 | 真空~0.14 MPa |

| 破裂時 | >22.0 MPa |

| 操作時 | 0.49~0.62 MPa |

| 使用温度範囲 | 10~200°C |

| 流量係数(Cv値) | 1.2(集積モデル) または1.7(ストレート型) |

| ボディ材質 | 316L VIM-VARステンレス鋼または合金22 |

| ベローズ材質 | 合金22(表面粗さ:0.13 μm仕上げ) |

| エンド・コネクション・タイプ(サイズ) | めすVCR®面シール継手(1/2 インチ)、回転可能型おすVCR継手(1/2 インチ)、チューブ突き合わせ溶接、長さ:12.7 mm(1/2 インチ X 肉厚1.24 mm)、集積モデル大流量用Cシール(1.5 インチ) |

ALDバルブの選定に関して質問がありますか?

ALD20シリーズ・バルブのカタログ

構成部品とその材質、使用圧力、使用温度、オプション、アクセサリーなど、製品に関する詳細情報につきましては、以下の資料をご参照ください。

ALD3, ALD6, and ALD7 Diaphragm Valves and ALD20 Bellows: Ultrahigh cycle life, high-speed actuation; Up to 392°F (200°C) w thermal actuators; Electronic actuator position-sensing; ultrahigh-purity applications; High flow capacity, PFA seat, Normally closed pneumatic actuation, Alloy 22 available

関連資料/コラム記事

최적의 합금으로 반도체 수율 향상

반도체 제조업체가 어떻게 하면 핵심 유체 시스템 부품에 적절한 합금을 선택하여 종합적인 생산 수율과 장기 수익성을 높일 수 있는지 알아보십시오.

Q&A: 반도체 제조의 과거와 현재, 그리고 미래

반도체 장비 OEM, 마이크로칩 제조업체, 유체 시스템 솔루션 제공업체가 어떻게 지난 몇십 년 동안 협력을 통해 반도체 시장이 무어의 법칙에 따른 수요를 충족하도록 해왔으며, 이제부터는 어떻게 해야 할 것인지 알아보십시오.

광섬유 장비 제조업체가 맞춤형 솔루션으로 효율을 높인 사례

로젠달 넥스트롬(Rosendahl Nextrom)은 1980년대부터 Swagelok에 의존하여 사업을 확장해왔습니다. 이 회사가 경쟁업체보다 앞서며 업계 리더 지위를 유지하도록 해준 솔루션에 대해 자세히 알아보십시오.

첨단 과학 분야에 필요한 신뢰성 높은 유체 시스템 솔루션

핀란드의 희석 냉동기 제조업체인 블루포스(Bluefors)가 양자 컴퓨팅과 실험물리학 등을 구현하는 데 Swagelok의 유체 시스템 부품과 솔루션을 신뢰하는 이유를 소개합니다.