Raccords Swagelok®

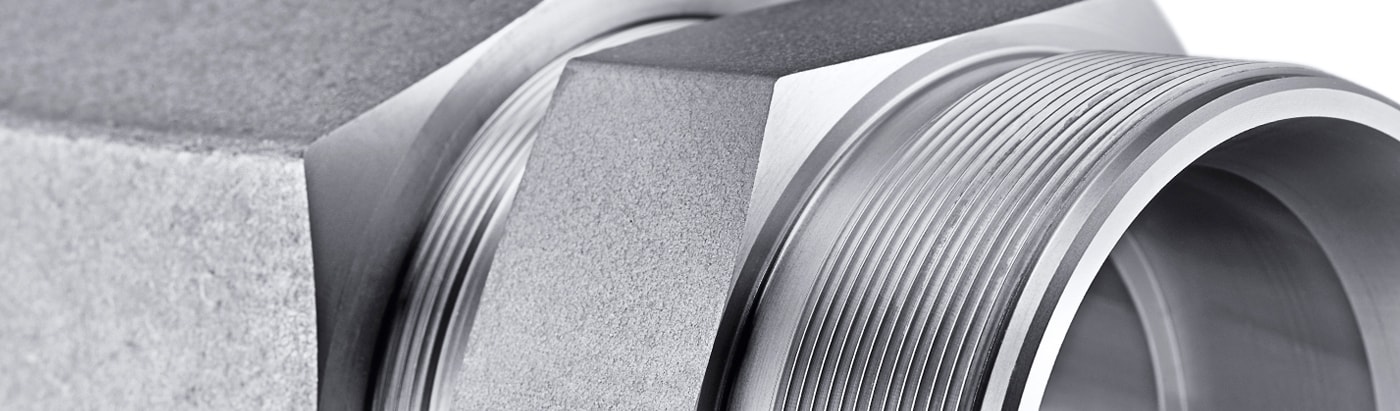

Fiables, étanches et faciles à installer, les produits Swagelok ont toutes les qualités pour garantir aux opérateurs de systèmes fluides industriels une exploitation sûre, efficace et rentable des procédés et des équipements.

Afficher tous les raccordsDepuis le lancement du raccord pour tube Swagelok® en 1947, les professionnels de l’industrie s’appuient sur les raccords Swagelok pour réaliser des raccordements étanches dans des systèmes fluides conçus pour l’analyse, l’instrumentation ou des procédés utilisant des tubes de faible diamètre. Que vous ayez besoin de raccords pour des environnements corrosifs, pour des températures extrêmes ou pour des pressions élevées, nous avons des solutions pour vous aider à créer des raccordements fiables. Nous proposons une gamme complète de raccords fabriqués dans divers alliages qui sauront répondre aux besoins de nombreuses applications industrielles, y compris celles qui ont des exigences particulières.

Les raccords Swagelok respectent des normes de qualité élevées grâce à des processus extrêmement contrôlés, ce qui permet aux utilisateurs d’avoir l’esprit tranquille au moment d’intégrer ces raccords polyvalents et ultraperformants dans la conception de leurs systèmes fluides. Si vous avez besoin d’une assistance technique ou d’une formation pour tirer le meilleur parti de ces produits dans vos systèmes, quelque 200 centres de vente et de services agréés Swagelok sont présents dans le monde entier pour vous aider.

Vous cherchez des conseils pour choisir et installer des raccords ?

Categorías de Racores

Racores para Tubo y Adaptadores

- Pasamuros

- Socket Weld Fittings

- Spare Parts and Accessories

- Tapones para tubo y tapones para racor

- Tube Adapters

Accesorios de PFA abocardados con rosca de paso fino

Los racores de PFA ofrecen la resistencia a la tracción, la estabilidad térmica y la resistencia al creep necesarios para la operación en aplicaciones de gran pureza como la producción de semiconductores.

Accesorios de cierre frontal con junta plana metálica VCR®

すべての Accesorios de cierre frontal con junta plana metálica VCR® をフィルターにかける

Accesorios de cierre frontal con junta tórica VCO®

すべての Accesorios de cierre frontal con junta tórica VCO® をフィルターにかける

Accesorios para soldar

- Adaptateurs à souder

- Raccords Micro-Fit haute pureté à souder bout à bout

- Raccords à souder bout à bout

- Raccords à souder par emboîtement

Catalogues des raccords

Trouver des informations détaillées sur nos produits – matériaux de fabrication, pressions et températures nominales, options, accessoires, etc.

The proven Swagelok® tube fitting design manufactured from corrosion-resistant alloy 2507 with NORSOK M0630 and M-650 compliance standard, NACE MR0175/ISO 15156 optional.

Features: Available in 1/4, 3/8, 1/2, 3/4 and 1 in. tube sizes; PFA and PVDF nut options; A wide variety of configurations

Manifolds et systèmes modulaires à montage direct ou distant pour instrumentation; Manifolds d’instrumentation à 2, 3 ou 5 vannes séries V, VB et VL ; Manifolds à 2, 3 ou 5 vannes pour montage direct série VE ; Manifolds à 2 vannes pour montage distant ; Systèmes d’instrumentation modulaires Mod 85

FK and IPT Series Products Cone and thread or medium-pressure tube fitting connections Excellent corrosion resistance in chloride-containing environmentsManufactured to meet NORSOK and NACE® MR0175/ISO15156

6 à 18 mm et 1/8 à 1 po.; Acier inoxydable 316, 316L, 316L VAR, et 316L VIM-VAR; Raccords pour soudure manuelle ou en automatique

Fabriqués en acier inoxydable, joint torique en élastomère fluorocarboné, Étanchéité d’une efficacité fiable et reproductible, Disponibles pour tubes aux dimensions allant de 1/16 à 1 1/2 po

Features: Metal components are machined from 316 stainless steel for use in rugged environments; Molded thermoplastic insulation with excellent electrical, chemical, and ultraviolet resistance and low water absorption maintains dielectric strength and integrity over a wide range of operating and climatic conditions; Gaugeable Swagelok® tube fitting or tapered pipe thread end connections (NPT/BSP) provide direct connection to tubing or piping system.

Caractéristiques : Transition des systèmes de tuyauterie à brides aux systèmes à tubes sans filetage ni soudure ; Différents types de brides conformes aux normes ASME, DIN, EN et JIS ; Corps forgé monobloc intégralement usiné ; Disponibles avec des raccords pour tubes Swagelok® de diamètre allant jusqu’à 50 mm ou 2 po

Disponibles pour tubes de 2 à 50 mm et de 1/16 à 2 po; Systématiquement contrôlable lors du montage initial; Facile à desserrer et à resserrer; Large gamme de matériaux et de configurations

Dimensions de 1/16 à 1 po.; Acier inoxydable 316, laiton et acier au carbone; Filetages NPT, ISO/BSP, et SAE.

Dimensions : 6 à 18 mm et 1/16 à 1 po.; Aciers inoxydables haute pureté; Le modèle original, la marque VCR authentique

■ Pressions nominales jusqu'à 4134 bar (60 000 psig)■ Dimensions des raccordements jusqu’à 1 1/2 po et 12 mm■ Produits conformes aux normes NACE® MR0175/ISO15156 disponibles

Pages 1-4. températures de 20 à 204 °C (70 à 400 °F) ; pressions de service jusqu’à 18,9 bar (275 psig) ; raccords à tube de 1/8 à 1/2 po.; tubes de 1/8 à 1 po. et de 6 à 12 mm.

Features: Suitable for liquid or gas chromatography; 316 stainless steel construction; Offered in sizes from 1/16 to 1/2 in.

Dimensions de cadran de 40, 50, 63, 100, 115, et 160 mm (1 1/2, 2, 2 1/2, 4, 4 1/2 et 6 po) ; Précision conforme aux normes ASME, EN, et JIS; Disponible avec différents raccordements d’extrémité, y compris les adaptateurs pour tubes Swagelok; Configurations pour montage arrière centré, montage arrière excentré et montage vertical; Construction en acier inoxydable et thermoplastique renforcé; Disponible avec ou sans liquide

Dimensions de 1/8 à 1 po, Acier inoxydable 316 ou 316L, Raccords pour tubes, NPT, filetage SAE et à souder

Les avantages du raccord pour tube Swagelok®

Avec une conception qui a fait ses preuves et une fabrication précise à partir de matières premières de qualité supérieure, les raccords pour tubes Swagelok sauront répondre à vos plus hautes attentes en matière de sécurité et de fiabilité.

Découvrir les avantagesLes ressources de Swagelok sélectionnées pour vous

Introduction aux raccords : déterminer le diamètre et le pas d’un filetage

Même les professionnels les plus aguerris peuvent avoir des difficultés à déterminer un filetage. Andy Hitchcock, responsable produit chez Swagelok, explique comment déterminer le diamètre et le pas des filetages de vos raccords à l’aide d’un pied à coulisse, d’un peigne à filet et d’un guide de détermination des filetages.

Une sécurité et une fiabilité accrues pour Shenyang Blower Works Group

Découvrez comment Swagelok Shanghai a aidé Shenyang Blower Works Group Corporation à faire faire des économies à ses clients grâce à des équipements plus fiables, tout en améliorant la sécurité de ses installations et le rendement de sa production.

Installation des raccords pour tubes Swagelok

Cette vidéo montre toutes les étapes de l’installation des raccords pour tubes Swagelok – des raccords qui ont acquis dans le monde entier une réputation de qualité et de fiabilité sur la durée.

Raccords Swagelok

Lorsque les entreprises les plus réputées au monde veulent des raccordements qui durent, elles se tournent vers Swagelok. Étanchéité, facilité d’installation, disponibilité, services d’assistance – nos raccords pour tubes sont la référence en la matière. Nos raccords en acier inoxydable double bagues ont acquis dans le monde entier une réputation de qualité et de fiabilité sur la durée. Cette réputation est le fruit des efforts que nous déployons pour améliorer continuellement nos produits ainsi que des performances de nos raccords dans des milliers d’applications les plus diverses.