Мембранные клапаны Swagelok® сверхвысокой степени чистоты для атомно-слоевого осаждения (серия ALD7)

Клапаны Swagelok серии ALD7 сверхвысокой степени чистоты обеспечивают стабильный расход и пропускную способность, быструю отработку, температурные параметры и уровень чистоты, помогающие увеличить выпуск чипов при использовании новых или имеющихся инструментов для производства полупроводников.

Запросить информацию о клапанах ALD7Мембранный клапан Swagelok® серии ALD7 для атомно-слоевого осаждения (ALD) дает возможность производителям полупроводников и изготовителям микросхем увеличить выход годной продукции, повысить рентабельность, обеспечить постоянство рабочего процесса при высоких температурах, что необходимо для преодоления ряда технических ограничений. Клапаны обеспечивают стабильность характеристик всех клапанов, во всех камерах и в дозировании в течение сверхвысокого циклического срока службы.

Клапан ALD7 от Swagelok:

- Обеспечивает быстрое и точное дозирование в течение миллионов циклов для самых строгих требований, и отличается усовершенствованной технологией со временем отклика всего 5 мс

- Устойчив к воздействию агрессивных газов благодаря корпусу из запатентованной сверхчистой нержавеющей стали Swagelok 316L VIM-VAR

- Возможность нагрева до 200°C при сохранении максимальной рабочей температуры пневматического привода ниже 150°C

- Обеспечивает коэффициент расхода (Cv) до 0,7 (доступны версии с индивидуальной заводской настройкой, обеспечивающие коэффициент расхода 0,5–0,7 Cv)

- Размеры аналогичны стандартным ALD-клапанам Swagelok, при этом оснащен встроенным термоизолятором для максимального использования ограниченного пространства возле реакционной камеры

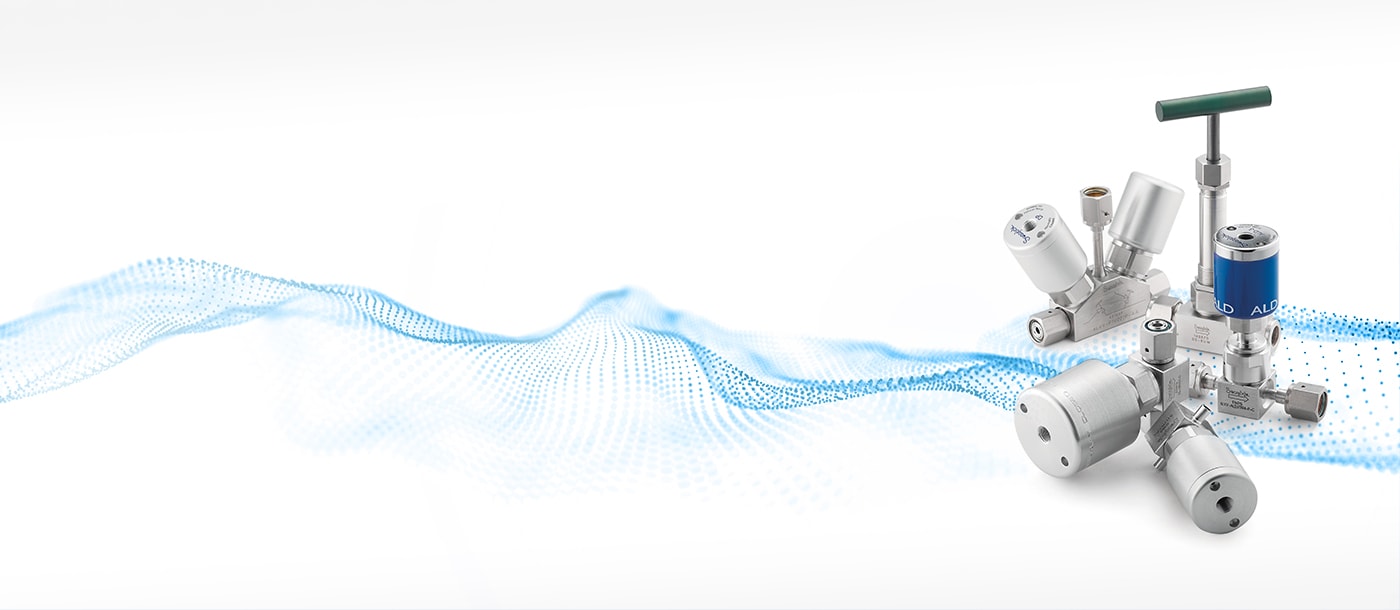

Клапаны ALD7, увеличенное изображение

Технические характеристики клапана ALD7

| Рабочее давление | От вакуума до 145 psig (10,0 бар ман) |

| Давление разрыва | > 3200 psig (220 бар ман) |

| Давление срабатывания | От 60 до 120 psig (от 4,1 до 8,27 бар ман) |

| Номинальная температура | Стандартный корпус клапана: от 32°F (0°C) до 392°F (200°C) |

| Коэффициент расхода | Стандартный коэффициент расхода 0,7 Cv (устанавливается в заводских условиях) |

| Материалы корпуса | Нерж. сталь 316L VIM-VAR |

| Материал мембраны | Специальный сплав на основе кобальта |

| Торцевые соединения | Тип: Фитинги VCR®, соединение под приварку встык, C-образное модульное уплотнение размером 1,5 дюйма с высоким расходом для монтажа на поверхность |

Есть вопросы о клапанах ALD?

Каталоги клапанов серии ALD7

Получите подробные сведения о продукции, в том числе о материалах изготовления, номинальных параметрах давления и температуры, вариантах исполнения и вспомогательных принадлежностях.

ALD 3, 6, and 7 Diaphragm Valves and ALD20 Bellows: Ultrahigh cycle life, high-speed actuation; Up to 392°F (200°C) w thermal actuators; Electronic actuator position-sensing; ultrahigh-purity applications; High flow capacity, PFA seat, Normally closed pneumatic actuation, Alloy 22 available

Способы решения основных проблем, связанных с обработкой полупроводников методом атомно-слоевого осаждения (ALD) и атомно-слоевого травления (ALE)

Для процесса обработки полупроводников методами атомно-слоевого осаждения (ALD) и атомно-слоевого травления (ALE) характерны определенные проблемы и сложности. Узнайте, как правильный выбор технологических клапанов поможет вам справиться с ними.

Выберите подходящие клапаны для решения задач в области атомно-слоевого осаждения (ALD)Ресурсы Swagelok специально для вас

Повышение выхода годных полупроводниковых изделий благодаря применению усовершенствованных сплавов

Узнайте, как производители полупроводников могут повысить выход годных изделий на каждом этапе производственного процесса, а также рентабельность в долгосрочной перспективе за счет правильного подбора металлов для важнейших компонентов жидкостных и газовых систем.

Вопросы и ответы. Полупроводниковое производство—вчера, сегодня, завтра

Узнайте, как сотрудничество между OEM-производителями оборудования, производителями микросхем и поставщиками решений для жидкостных и газовых систем позволило полупроводниковой отрасли десятилетиями придерживаться закона Мура, а также о том, куда двигаться дальше.

Производитель оптоволоконного оборудования повышает эффективность с помощью индивидуальных решений

С 1980-х годов Rosendahl Nextrom полагается на компанию Swagelok в развитии своего бизнеса. Узнайте больше о решениях, которые позволили компании опередить конкурентов и остаться в числе отраслевых лидеров.

Надежные решения в жидкостных и газовых системах для новых научно-исследовательских возможностей

Узнайте, почему финская компания-производитель криогенных рефрижераторов Bluefors доверяет компонентам и решениям Swagelok для жидкостных и газовых систем, которые способствуют развитию сферы квантовых вычислений, экспериментальной физики и других направлений.