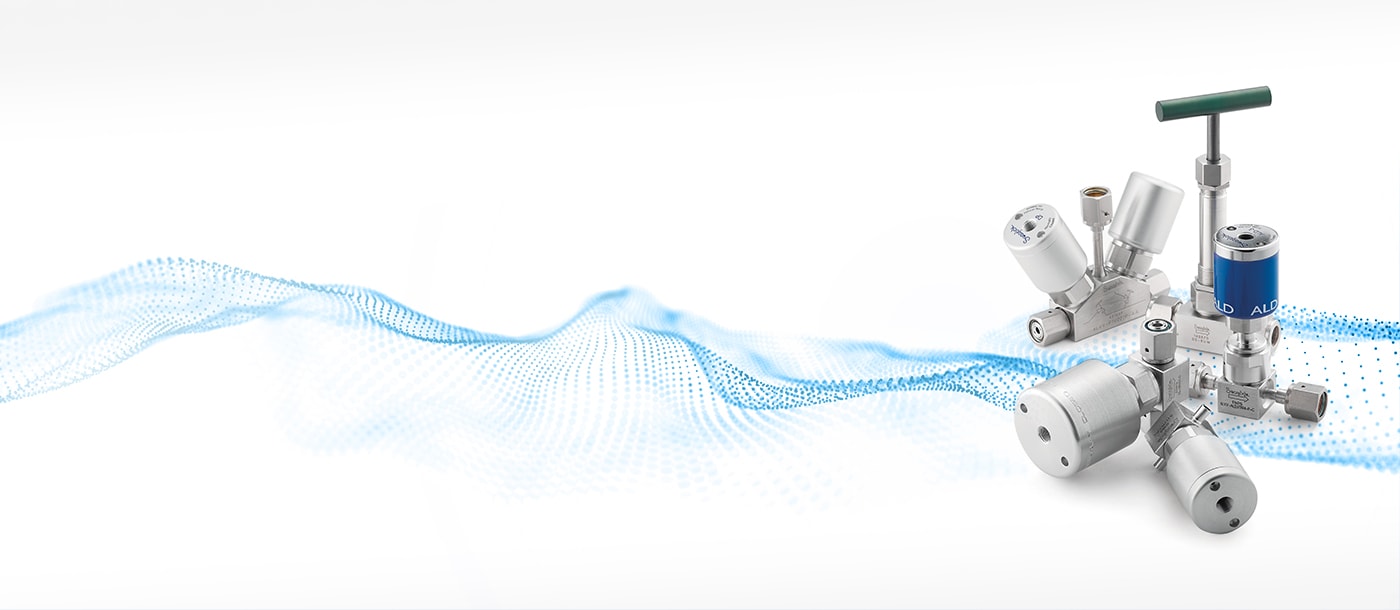

Swagelok® Ultrahochreine Membranventile für die Atomlagenabscheidung der Serie ALD7

Das ultrahochreine ALD7-Ventil von Swagelok sorgt dafür, dass das Durchflussverhalten, die Durchflusskapazität, die Betätigungsgeschwindigkeit, die Temperaturwerte sowie die Reinheit sichergestellt sind, die zur Maximierung des Chip-Durchsatzes in neuen oder existierenden Halbleiterproduktionsanlagen erforderlich sind.

Informationen zu ALD7-Ventilen anfordernDas ultrahochreine Swagelok® Membranventil ALD7 für die Atomlagenabscheidung (ALD) ermöglicht es Herstellern von Halbleiter-Fertigungsanlagen sowie Chipherstellern, die Chipausbeute zu erhöhen und die Rentabilität zu steigern. Für höchste Prozessanforderungen konzipiert, überzeugt das ALD 7-Ventil durch optimales Durchflussverhalten und eine optimale Durchflusskapazität, eine hohe Betätigungsgeschwindigkeit sowie Leistungsstärke in hohen Temperaturbereichen. Das ALD 7-Ventil bietet eine konstant hohe Leistung von Ventil zu Ventil, Dosis zu Dosis und Kammer zu Kammer bei maximaler Lebensdauer.

Vorteile des ALD 7-Ventils von Swagelok:

- Schnelle und präzise Dosierung über Millionen von Produktionszyklen auch in anspruchsvollsten Anwendungen und verbesserte Stellantriebstechnologie mit einer Ansprechzeit von nur 5 ms

- Beständigkeit gegen korrosive Gase dank Swagelok-Ventilkörper aus Edelstahl 316L VIM-VAR für ultrahochreine Anwendungen

- Aufheizbar bis 200 °C, solange der pneumatische Antrieb unter der maximalen Betriebstemperatur von 150 °C bleibt

- Bietet einen Durchflusskoeffizient (Cv) von bis zu 0,7; optional sind kundenspezifische Ausführungen (werkseitig eingestellt) mit Durchflusskoeffizienten von 0,5 bis 0,7 Cv erhältlich

- Gleicher Platzbedarf wie ALD-Ventile nach Industriestandard von Swagelok und integrierter Wärmeisolator zur maximalen Ausnutzung des begrenzten Platzes nahe der Reaktionskammer

ALD7-Ventile – Spezifikationen

| Betriebsdruck | Vakuum bis 10,0 bar (145 psig) |

| Berstdruck | >220 bar (3.200 psig) |

| Betätigungsdruck | 4,1 bis 8,27 bar (60 bis 120 psig) |

| Auslegungstemperatur | Standardventilkörper von 0 °C (32 °F) bis 200 °C (392 °F) |

| Durchflusskoeffizient | Standardmäßig 0,7 Cv (werkseitig) |

| Körperwerkstoffe | Edelstahl 316L VIM-VAR |

| Membranwerkstoff | Superlegierung auf Kobaltbasis |

| Endanschlüsse | Typ: VCR®-Verbindungen, 1,5 Zoll, Stumpfschweißfitting, modulare Konfiguration mit C-Dichtung für hohe Durchflusskapazitäten |

Sie haben Fragen zu ALD-Ventilen?

Ventile der Serie ALD7—Kataloge

Hier finden Sie ausführliche Produktinformationen zu Werkstoffen, Druckstufen, Auslegungstemperaturen, Optionen und Zubehör.

ALD 3, 6, and 7 Diaphragm Valves and ALD20 Bellows: Ultrahigh cycle life, high-speed actuation; Up to 392°F (200°C) w thermal actuators; Electronic actuator position-sensing; ultrahigh-purity applications; High flow capacity, PFA seat, Normally closed pneumatic actuation, Alloy 22 available

Wie Sie Herausforderungen bei der Halbleiterherstellung mittels ALD und ALE meistern

Die Fertigungsprozesse von Halbleitern mittels ALD und ALE sind mit inhärenten Herausforderungen und Komplexitäten verbunden. Erfahren Sie, wie Sie diese durch Auswahl der geeigneten Prozessventile erfolgreich meistern können.

Wählen Sie die richtigen Ventile für ALD-HerausforderungenSwagelok-Ressourcen für Sie zusammengestellt

Verbessern Sie Ihre Halbleiterproduktion durch den Einsatz optimierter Legierungen

Erfahren Sie, wie Halbleiterhersteller ihre Produktionsausbeute und Profitabilität durch Auswahl der passenden Werkstoffe für wichtige Fluidsystemkomponenten langfristig optimieren.

Q&A: Entwicklungen und Trends in der Halbleiterherstellung

In diesem Artikel beschäftigen wir uns damit, wie die Zusammenarbeit zwischen Herstellern von Halbleiter-Fertigungsanlagen, Chipproduzenten und Fluidsystemanbietern in der Halbleiterindustrie über Jahrzehnte hinweg dazu beigetragen hat, dass das Mooresche Gesetz eingehalten werden konnte. Zudem werfen wir einen Blick in die Zukunft dieser schnelllebigen Branche.

Hersteller für Glasfaserproduktionssysteme erhöht seine Effizienz durch maßgeschneiderte Lösungen für seine Kunden

Bereits seit den 1980er-Jahren setzt Rosendahl Nextrom auf die Zusammenarbeit mit Swagelok, um sich geschäftlich weiterzuentwickeln. Erfahren Sie mehr über die Lösungen, mit denen es der Firma gelungen ist, der Konkurrenz stets einen Schritt voraus zu sein und sich als Marktführer zu behaupten.

Zuverlässige Fluidsystemlösungen für die Wissenschaft

Erfahren Sie mehr darüber, warum sich das finnische Unternehmen Bluefors bei der Herstellung seiner Mischungskryostate für Anwendungen in den Bereichen Quantum-Computing und Experimentalphysik auf die Fluidsystemkomponenten und -lösungen von Swagelok verlässt.