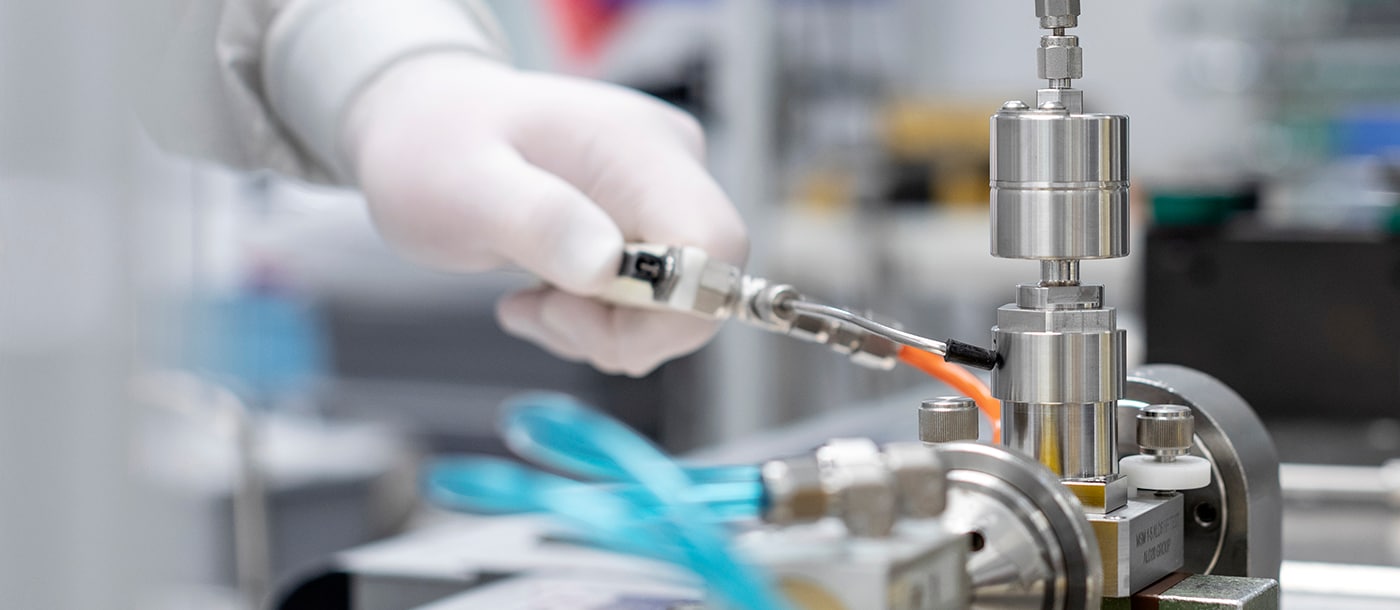

Swagelok® Atomic Layer Deposition (ALD) Valves

Swagelok ultrahigh-purity atomic layer deposition (ALD) valves offer the ultrahigh cycle life, high-speed actuation, flow rates, thermal immersibility, and extreme cleanliness needed to enable precise dosing and maximize chip yield in advanced semiconductor manufacturing applications.

Request ALD Valve InformationSince introducing the world to ALD valves, we have worked closely with semiconductor tool OEMs and fabs to deliver advanced ALD valve technology that provides the extreme levels of precision, consistency, cleanliness, and high cycle life necessary to keep up with the quick pace of innovation in the marketplace. Swagelok® ALD valves can support increased chip production efficiency and overcome the challenges that are often associated with ALD processes.

Our ALD ultrahigh-purity valves feature:

- Ultrahigh cycle life with high-speed actuation

- Cv ranging from 0.27 to 1.7

- Temperature capability up to 392°F (200°C) for specified models

- Electronic or optical actuator position-sensing option

- Cleanliness suitability for ultrahigh-purity applications

- Modular surface mount, tube butt weld, and VCR® end connections

Atomic Layer Deposition (ALD) Valves Categories

Ultrahigh-Purity Diaphragm Valves, ALD3 and ALD6 Series

ALD3 and ALD6 diaphragm valves offer ultrahigh cycle life, high-speed actuation, and strong performance in atomic layer deposition applications.

Ultrahigh-Purity Diaphragm Valves, ALD7 Series

The Swagelok® ALD7 ultrahigh-purity diaphragm valve offers the precision and consistency needed to maximize chip yields in semiconductor manufacturing applications.

Ultrahigh-Purity Valves for High-Flow Applications, ALD20 Series

Advance atomic layer deposition technology with flow rates 2–3x higher than other ALD valves with the ALD20 ultrahigh-purity valve.

Atomic Layer Deposition (ALD) Valve Catalogs

Locate detailed product information, including materials of construction, pressure and temperature ratings, options, and accessories.

ALD 3, 6, and 7 Diaphragm Valves and ALD20 Bellows: Ultrahigh cycle life, high-speed actuation; Up to 392°F (200°C) w thermal actuators; Electronic actuator position-sensing; ultrahigh-purity applications; High flow capacity, PFA seat, Normally closed pneumatic actuation, Alloy 22 available

One New Valve: Three Reasons It Could Change Semiconductor Manufacturing

Find out how the latest innovation in atomic layer deposition (ALD) valve technology is changing the game for high-tech semiconductor manufacturers.

Unlock More of the Periodic TableSwagelok Resources Curated for You

Improve Semiconductor Yield with Optimized Alloys

Discover how semiconductor fabricators can improve end-to-end production yields and improve long-term profitability by selecting the right metals for critical fluid system components.

Q&A: Semiconductor Manufacturing Past, Present, and Future

Find out how collaboration between semiconductor tool OEMs, microchip manufacturers, and fluid system solutions providers has enabled the semiconductor market to keep up with the demands of Moore’s Law for decades, and where we go from here.

Производитель оптоволоконного оборудования повышает эффективность с помощью индивидуальных решений

С 1980-х годов Rosendahl Nextrom полагается на компанию Swagelok в развитии своего бизнеса. Узнайте больше о решениях, которые позволили компании опередить конкурентов и остаться в числе отраслевых лидеров.

Надежные решения в жидкостных и газовых системах для новых научно-исследовательских возможностей

Узнайте, почему финская компания-производитель криогенных рефрижераторов Bluefors доверяет компонентам и решениям Swagelok для жидкостных и газовых систем, которые способствуют развитию сферы квантовых вычислений, экспериментальной физики и других направлений.