Swagelok® 피팅

Swagelok 피팅은 유체 시스템 운영업체에 공정과 장비를 계속 안전하고 효율적으로 운영하는 데 필요한 신뢰성, 설치 편의성, 누설 없는 성능을 제공합니다.

모든 피팅 보기1947년 Swagelok® 튜브 피팅이 발표된 이래로, 업계 전문가들은 Swagelok 피팅에 의존하여 분석, 계장, 소구경 공정 유체 시스템에서 누설 없는 연결을 실현해 왔습니다. 부식성 환경, 극한의 온도 또는 고압에 대응하는 피팅이 필요한 경우를 막론하고, Swagelok은 고객이 신뢰할 수 있는 연결을 구축하는 데 도움이 되는 신뢰성 높은 옵션을 제공합니다. Swagelok은 특별한 요구 조건이 있는 경우를 포함하여 광범위한 산업용 애플리케이션에 대응하는 다양한 합금 재질의 완벽한 피팅 포트폴리오를 공급할 수 있습니다.

Swagelok 피팅은 고도로 통제된 공정을 통해 높은 품질 기준을 유지하며, 따라서 사용자가 Swagelok의 다기능, 고성능 피팅을 자사 유체 시스템 구조에 안심하고 통합할 수 있습니다. 시스템에 Swagelok 제품을 최적으로 활용하는 데 기술 지원 또는 교육이 필요하다면, 전 세계 거의 200곳에 달하는 공인 Swagelok 판매 및 서비스 센터에서 도움을 받을 수 있습니다.

피팅 선택 및 설치와 관련된 조언을 구하고 있습니까?

Catégories de raccords

Raccords et adaptateurs pour tubes

- Adaptateurs pour tubes

- Adaptateurs pour tubes fusibles

- Capuchons et bouchons

- Connecteurs femelles

- Connecteurs mâles

Raccords VCR® à étanchéité de surface avec joint métallique

Фильтровать всеRaccords VCR® à étanchéité de surface avec joint métallique

Raccords pour tubes moyenne pression

- Запасные части и вспомогательное оборудование

- Колпаки и заглушки

- Муфты

- С монтажной гайкой

- Соединители с внутренней резьбой

Raccords à souder

- Переходники под приварку

- Фитинги Micro-Fit высокой степени чистоты под приварку встык

- Фитинги под приварку враструб

- Фитинги со сварным соединением встык

Raccords à étanchéité de surface avec joint torique VCO®

- Втулки

- Запасные части и вспомогательное оборудование

- Муфты

- С монтажной гайкой

- Соединители с внутренней резьбой

Raccords évasés à filetage fin en PFA

Les raccords en PFA offrent la résistance à la traction, la stabilité thermique et la résistance au fluage nécessaires pour une utilisation dans des applications haute pureté comme la production des semi-conducteurs.

피팅 카탈로그

구성 재질, 압력 및 온도 등급, 옵션, 액세서리를 포함한 자세한 제품 정보를 찾을 수 있습니다.

The proven Swagelok® tube fitting design manufactured from corrosion-resistant alloy 2507 with NORSOK M0630 and M-650 compliance standard, NACE MR0175/ISO 15156 optional.

Предлагаются для трубок размером 1/4, 3/8, 1/2, 3/4 дюйма и 1 дюйм; Варианты исполнения гаек из перфторалкокси (PFA) и поливинилиденфторида (PVDF); Широкий выбор конфигураций

Приборные двух-, трех- и пятиклапанные блоки серий V, VB и VL; двух-, трех- и пятиклапанные блоки прямого монтажа серии VE; двухклапанные блоки выносного монтажа; модульные контрольно-измерительные системы Mod 85

FK and IPT Series Products Cone and thread or medium-pressure tube fitting connections Excellent corrosion resistance in chloride-containing environmentsManufactured to meet NORSOK and NACE® MR0175/ISO15156

От 6 до 18 мм и от 1/8 до 1 дюйма; Материалы: нержавеющая сталь 316, 316L, 316L VAR и 316L VIM-VAR; Фитинги для установки с помощью оборудования для ручной или автоматической сварки

Конструкция из нержавеющей стали, уплотнительное кольцо из фторуглерода FKM, Надежное повторяемое соединение, Предлагаются для трубок размером от 1/16 до 1 1/2 дюйма

Features: Metal components are machined from 316 stainless steel for use in rugged environments; Molded thermoplastic insulation with excellent electrical, chemical, and ultraviolet resistance and low water absorption maintains dielectric strength and integrity over a wide range of operating and climatic conditions; Gaugeable Swagelok® tube fitting or tapered pipe thread end connections (NPT/BSP) provide direct connection to tubing or piping system.

Характеристики: Безрезьбовой и бесшовный переход от фланцев толстостенных трубопроводов к тонкостенным трубопроводам. Типы фланцев соответствуют стандартам ASME, DIN, EN и JIS. Цельнокованый корпус с полной обработкой. Предлагаются с торцевыми трубными обжимными фитингами Swagelok® до 50 мм и до 2 дюймов.

Swagelok® tube fittings and tube adapters reduce the risk of costly system downtime with reliable tubing connections and are available in a variety of sizes and materials.

Размеры от 1/16 до 1 дюйма; Изготавливаются из нержавеющей стали марки 316, латуни и углеродистой сталиl; Резьбы NPT, ISO/BSP и SAE

Размеры от 6 до 18 мм и от 1/16 до 1 дюйма; Нержавеющие стали высокой степени чистоты; Оригинальная конструкция, подлинная марка VCR

Характеристики: конструкция из нержавеющей стали 316; температура до 1000 °F (537 °C); фитинги среднего давления, диаметр от 1/4 до 1 дюйма, номинальное давление до 20 000 фунтов на кв. дюйм, ман. (1378 бар); фитинги высокого давления, диаметр от 1/4 до 9/16 дюйма, номинальное давление до 60 000 фунтов на кв. дюйм, ман. (4134 бар); предлагаются варианты исполнения, соответствующие стандарту NACE® MR0175 / ISO15156

Температура от 20 до 204 °C (от 70 до 400 ºF); Рабочее давление до 18,9 бара (275 фунтов на кв. дюйм, ман.); Размеры от 1/8 до 1/2 дюйма

Характеристики: пригодны для жидкостной и газовой хроматографии; конструкция из нержавеющей стали 316; предлагаются размеры от 1/16 до 1/2 дюйма.

Размеры циферблата 40, 50, 63, 100, 115 и 160 мм (1 1/2, 2, 2 1/2, 4, 4 1/2 и 6 дюймов); Точность в соответствии со стандартами ASME, EN и JIS; Поставляются с различными торцевыми соединениями, в том числе с трубными переходниками Swagelok®; Конфигурации с креплением позади корпуса по центру, позади внизу и снизу; Конструкция из нержавеющей стали и армированного термопласта; Предлагаются варианты исполнения с жидкостным наполнением и без наполнения

Размер от 1/8 до 1 дюйма, Нержавеющая сталь марки 316 или 316L, Торцевые соединения под трубку с резьбами NPT, SAE и сварные соединения

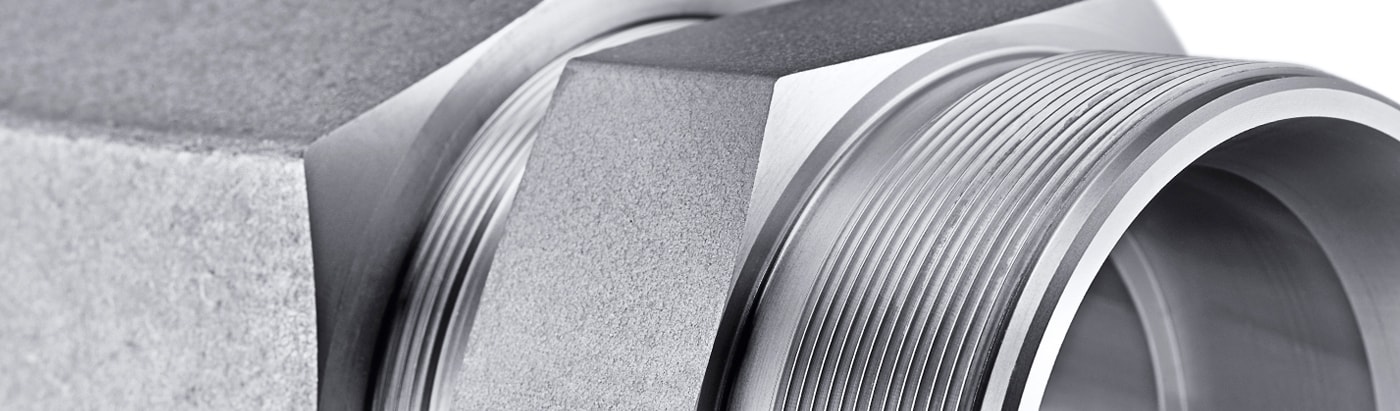

Swagelok® 튜브 피팅의 장점

Swagelok 튜브 피팅은 검증된 설계, 정밀 제조 공정, 최고급 원자재로 생산되므로 안전성과 신뢰성 측면에서 고객의 가장 높은 기대치도 충족할 수 있습니다.

장점 알아보기고객별 맞춤 선별 Swagelok 리소스

피팅 소개: 나사 크기 및 피치 식별

경력이 많은 전문가도 가끔 나사산을 확인하기 어려울 때가 있습니다. Swagelok 제품 매니저 Andy Hitchcock이 캘리퍼, 피치 게이지, 나사산 식별 가이드를 통해 피팅의 나사산 크기와 피치를 확인하는 방법을 설명합니다.

선양 고풍기 유한공사(Shenyang Blower Works Group)의 안전 및 신뢰성 개선 사례

선양 고풍기 유한공사(Shenyang Blower Works Group)가 안전과 생산 효율성을 개선하는 동시에, 일관성, 신뢰성, 고객 비용 절감을 실현할 수 있도록 Swagelok Shanghai가 어떻게 지원했는지 알아보십시오.

Swagelok 튜브 피팅 설치

이 비디오는 일관성, 품질, 신뢰성 측면에서 국제적인 명성을 쌓아온 Swagelok 튜브 피팅을 설치하는 필수 단계를 보여줍니다.

Swagelok 피팅

세계적으로 명성이 높은 기업들도 수명이 긴 연결이 필요할 때는 Swagelok을 찾습니다. Swagelok은 누설 없는 밀폐 무결성, 손쉬운 설치, 가용성, 지원 서비스와 관련하여 튜브 피팅 성능의 표준을 정립했습니다. Swagelok 2 페럴 스테인리스강 튜브 피팅은 일관성, 품질, 신뢰성 측면에서 세계적인 평판을 확보했습니다. 이러한 평판은 Swagelok의 지속적인 제품 개선 노력과 수천 가지 다양한 애플리케이션에서 입증된 피팅 성능으로 뒷받침됩니다.