Swagelok® Pressure-Reducing Regulators, Dome-Loaded

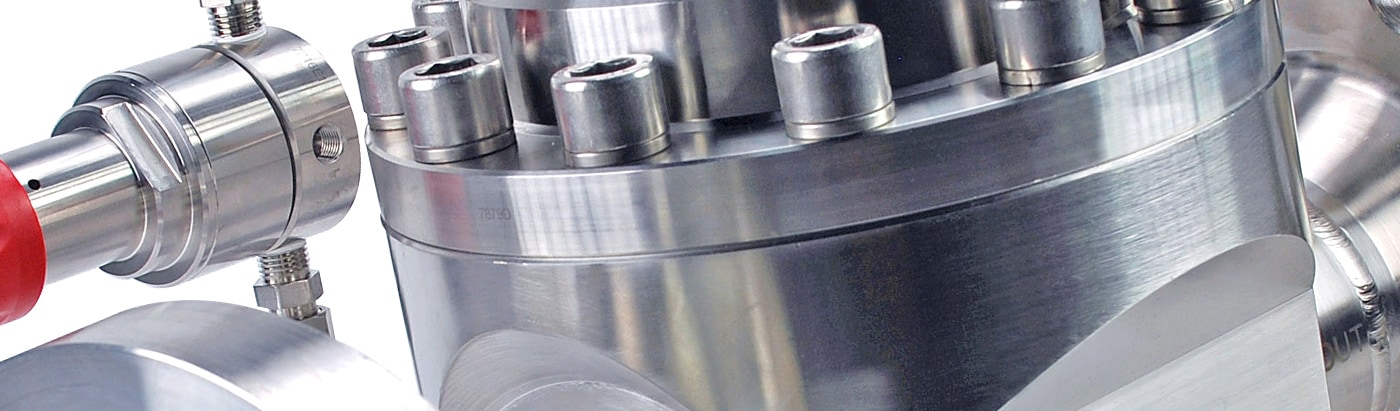

General Industrial (SGRD Series) and High Sensitivity (SHRD Series) pressure-reducing, dome-loaded regulators are suitable for a wide variety of industrial applications where manual or remote operation of the regulator and accurate set pressure control is desired.

Get Help Selecting Process RegulatorsSGRD and SHRD series regulators are engineered for durability in demanding environments. Their bodies are constructed from 316L stainless steel, enhancing corrosion resistance and longevity. These regulators feature internal seals available in various materials, providing improved compatibility with a wide range of chemicals and pressure conditions.

Pressure-reducing, dome-loaded regulators offer superior performance in maintaining stable outlet pressures. By utilizing a pressure dome instead of a set spring for control, these regulators effectively minimize droop. This design ensures consistent outlet pressures, regardless of fluctuations in inlet pressure or flow variations.

SGRD and SHRD Series Features

- Balanced poppet

- Diaphragm sensing

- Non-venting

- Pilot regulator control

Customizable Features

- External feedback to pilot

- Differential pressure pilot (SGRD Series)

- Dual stage pilot (SGRD Series)

- Antitamper / factory set pilot handle

- NACE MR0175/ISO 15156

Learn About Types of Regulators

General Industrial Pressure-Reducing, Dome-Loaded Regulators (SGRD Series)

Specifications

| Body Size | Maximum Inlet Pressure psig (bar) | Maximum Outlet Pressure psig (bar) | Adjustable Pressure Range psig (bar) | Sensing Type psig (bar) | Temperature Range °F (°C) | Flow Coefficient (Cv) | Minimum Weight lb (kg) |

|---|---|---|---|---|---|---|---|

| 12 | 6000 (413) | 6000 (413) | 5 to 6000 (0.3 to 413) | Diaphragm: 5 to 6000 (0.3 to 413) | –49 to 356° (–45 to 180°) | 2.3 | 9.7 (4.4) |

| 16 | 4.8 | 26.5 (12.0) | |||||

| 24 | 10.7 | 27.6 (12.5) |

High Sensitivity Pressure-Reducing, Dome-Loaded Regulators (SHRD Series)

Specifications

| Body Size | Maximum Inlet Pressure psig (bar) | Maximum Outlet Pressure psig (bar) | Adjustable Pressure Range psig (bar) | Sensing Type psig (bar) | Temperature Range °F (°C) | Flow Coefficient (Cv) | Minimum Weight lb (kg) |

|---|---|---|---|---|---|---|---|

| 12 | 250 (17.2) | 250 (17.2) | 1 to 250 (0.07 to 17.2) | Diaphragm: 1 to 250 (0.07 to 17.2) | –49 to 356° (–45 to 180°) | 2.3 | 9.7 (4.4) |

| 16 | 4.8 | 26.5 (12.0) | |||||

| 24 | 10.7 | 27.6 (12.5) |

Pressure-Reducing, Dome-Loaded Process Regulators Catalog

Locate detailed product information, including materials of construction, pressure and temperature ratings, options, and accessories.

Merkmale: Druckminderungsregler, Vordruckregler; Feder-, Dom- und luftbelastet; 1/4 bis 4 Zoll Endanschlüsse; Arbeitsdrücke bis 7 bar (10 150 psig); Temperaturen von –20 bis 80°C (–4 to 176°F)

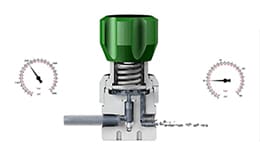

Ein Druckregler hat ein Regelelement (Kolben oder Membran), das an einer Seite einer Belastungskraft (FS) ausgesetzt wird, die von einer Feder (wie unten abgebildet) oder einem Gasdruck erzeugt wird. Auf der anderen Seite wird das Erfassungselement der Kraft (F) des Systemfluid ausgesetzt.

Need Help Selecting the Right Regulators?

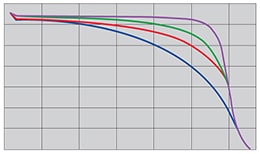

Compare the performance of different regulators under varying application conditions with our regulator flow curve generator tool.

Find the Right RegulatorSwagelok Resources Curated for You

Managing Supply Pressure Effect (SPE) in a Regulator

Supply pressure effect, also known as dependency, is an inverse relationship between inlet and outlet pressure variables within a regulator. Learn how to manage this phenomenon in your pressure regulators with tips from Swagelok.

철저한 테스트가 신뢰성 높은 레귤레이터 성능을 보장하는 이유

극한 조건에서 올바르게 작동하도록 제품을 설계하려면 어떤 테스트가 필요할지 궁금하십니까? 영하의 온도에서도 작동하는 Swagelok RHPS 시리즈 산업용 레귤레이터의 개발 과정을 따라가면서 어떻게 설계되는지 알아보십시오.

레귤레이터 유량 곡선을 평탄화하여 드룹(droop)을 줄이는 방법

드룹(droop)은 모든 감압 레귤레이터에서 발생하는 공통된 문제입니다. 다양한 돔 하중 레귤레이터 구성을 사용하여 드룹(droop)을 최소화하고 레귤레이터 유량 곡선을 평탄화하는 방법을 알아보십시오.

분석 계장 시스템에서 레귤레이터를 사용하여 시간 지연을 줄이는 방법

시간 지연 문제는 종종 분석 시스템에서 과소 평가되거나 오해를 받습니다. 이러한 문제를 완화하는 방법 중 하나는 압력 제어 레귤레이터를 사용하는 것입니다. 이러한 팁을 통해 분석 시스템의 시간 지연을 관리하는 방법을 알아보십시오.