Swagelok® Lubricants

Swagelok Goop™ thread lubricant reduces installation time by easing the assembly of leak-tight threaded connections for a variety of metals and alloys.

View LubricantsOur wide selection of Swagelok Goop™ thread lubricants makes assembling leak-tight connections quicker and easier. Swagelok Goop is available in oil, halocarbon, and fluourosilicone-based varieties. They are rated for use with a variety of materials and in a variety of applications, including vacuum systems.

- Silver Goop is oil-based thread lubricant for use on stainless steel and high-temperature alloys. It prevents galling, contains a non-melting antiseize agent, lowers torque on threaded parts, and stays in place between mating surfaces.

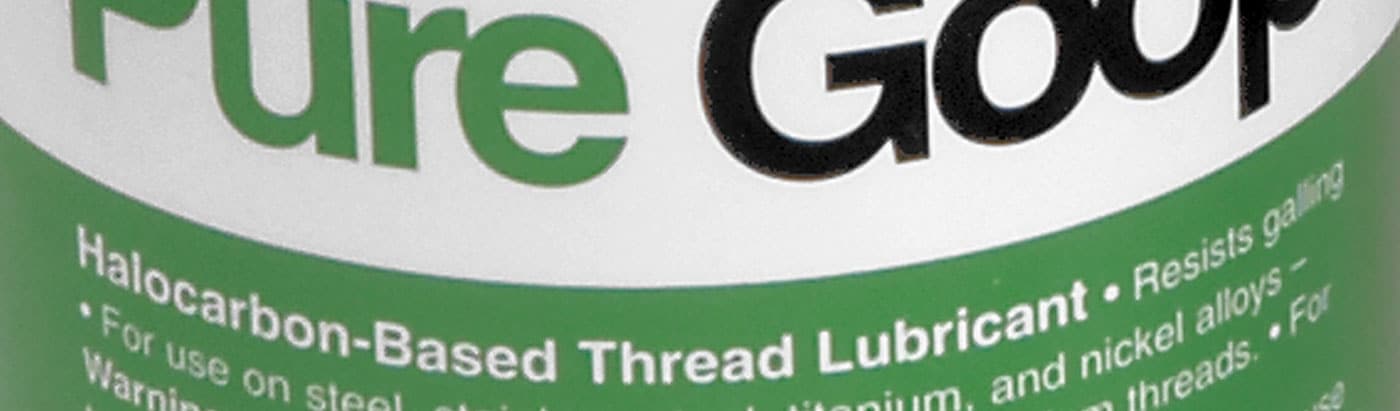

- Pure Goop is halocarbon-based thread lubricant for use on titanium, stainless steel, steel, and nickel-based alloys. It resists galling and moisture and is chemically nonreactive with a wide range of materials.

- Blue Goop is oil-based thread lubricant for use on stainless steel, titanium, aluminum, and nickel-based alloys. It resists galling and water washout and its deep blue color is unaffected by water.

- Vac Goop is fluorosilicone-based thread lubricant for use on threads, O-rings, gaskets, glass seals, and metal parts in vacuum systems. It resists galling, has extremely low vapor pressure, minimizes outgassing problems, and is chemically nonreactive with a wide range of materials.

Have questions about thread lubricants?

Categorías de Lubricantes

Lubricante para Roscas

Conozca los lubricantes para roscas que facilitan el montaje de conexiones estancas para una gran variedad de metales y aleaciones.

Lubricants Catalogs

Locate detailed product information, including materials of construction, pressure and temperature ratings, options, and accessories.

Detectores de fugas líquidos Snoop®; Lubricantes para roscas Goop™ ; Sellante para roscas SWAK®, cinta de PTFE y sellante sin PTFE

Compressed Gas Leak Detection Services

Receive help identifying and quantifying compressed gas leaks so you can prioritize the most critical issues to address based on potential for emissions reduction and safety, cost, and productivity improvement.

Learn About Leak Detection ServicesSwagelok Resources Curated for You

Leak Detection Case Studies

Swagelok fluid system specialists with deep technical and application expertise regularly help customers find, address, and prevent leaks in their fluid systems. Find out how those customers have benefited.

Common Causes and Costs of Fluid System Leaks

The smallest leak can present a serious issue when maintaining your plant’s safety and profitability. Understand how and why leaks occur, how to locate and test for them, and ultimately how to develop a strategy to address and reduce leaks plant-wide.

Combating Common Fluid System Leaks in Tire Facilities

Tire manufacturers can grow accustomed to leaking process pipes, but system leaks can pose significant safety hazards and drain profitability. Learn how to identify common leak sources throughout a plant and how to fix them.

How to Avoid System Leaks: The Importance of Proper Tube Preparation

A successful tube fitting installation depends on many criteria, but one of the most important is proper tube preparation before installation. Learn to avoid costly or dangerous leaks by avoiding damaged, burred, or improperly cut tubes.