Swagelok® Редукторы для переключения газовых баллонов

Регуляторы серии KCM автоматически переключают источники газа, обеспечивая непрерывный поток и сокращая время простоя оборудования.

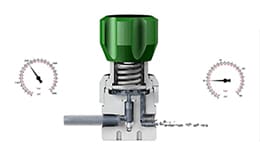

Помощь с выбором регуляторовРегуляторы Swagelok для переключения газовых баллонов (серия KCM) автоматически переключаются между двумя источниками газа для поддержания его непрерывного расхода в критически важных промышленных системах, одновременно сокращая время простоя и трудозатраты. Конструкция устройств предусматривает надежное газораспределение с минимальным контролем и объемом технического обслуживания. Неперфорированные гофрированные мембраны регуляторов серии KCM обеспечивают долговечность и более эффективный отклик на изменение давление.

Технические характеристики

| Максимальное давление на входе | 4351 psig (300 бар ман) с седлом из PEEK 3600 psig (248 бар ман) Баллонные соединения и шланговые фитинги могут ограничивать номинальное давление на входе. |

| Диапазоны регулирования давления | 0–10 psig (0,68 бар ман) до 0–500 psig (34,4 бар ман) |

| Номинальные значения давления переключения | 100, 250 и 500 psig (6,8; 17,2 и 34,4 бар ман) |

| Коэффициент расхода (Cv) | 0,06 |

| Максимальная рабочая температура | 176°F (80°C) с седлом из PCTFE 392°F (200°C) с седлом из PEEK 212°F (100°C) с седлом из PEEK и максимальным давлением на входе свыше 3600 psig (248 бар ман) |

Каталоги редукторов для переключения газовых баллонов

Найдите исчерпывающие сведения о редукторах для переключения газовых баллонов, в том числе материалы конструкции, вспомогательные принадлежности, номинальные значения давления и температуры.

Swagelok offers pressure-reducing, back-pressure, dome-loaded, and spring-loaded pressure regulators to control pressure and minimize droop in instrumentation systems.

Нужна помощь с выбором подходящего регулятора?

Узнайте больше из наших видеоматериалов о правильном выборе регулятора для разных условиях эксплуатации.

Поиск подходящего регулятораРесурсы о регуляторах Swagelok

Минимизация эффекта нагнетаемого давления (SPE) в регуляторе

Эффект нагнетаемого давления представляет собой обратную зависимость между значениями давления на входе и выходе регулятора. Узнайте, как минимизировать это явление в регуляторах от экспертов компании Swagelok.

Как тщательные испытания гарантируют надежность работы регулятора

Вы когда-нибудь задавались вопросом, какие испытания проходят изделия, предназначенные для работы в экстремальных условиях? Загляните в лабораторию и узнайте историю разработки промышленных регуляторов серии RHPS для эксплуатации при сверхнизких температурах.

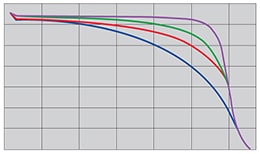

Как выпрямить кривую расхода регулятора, чтобы снизить потери давления

Потеря давления является проблемой для каждого редуктора. Узнайте, как свести к минимуму такой эффект и выпрямить кривую расхода с помощью целого ряда вариантов куполовидных регуляторов.

Применение регулятора для уменьшения временной задержки в аналитической контрольно-измерительной системе

Временную задержку в аналитических системах часто недооценивают или неправильно интерпретируют. Одним из способов уменьшить эту задержку является регулятор, управляемый давлением среды. Изучите приведенные рекомендации, которые помогут узнать, как уменьшить временную задержку в аналитической системе.