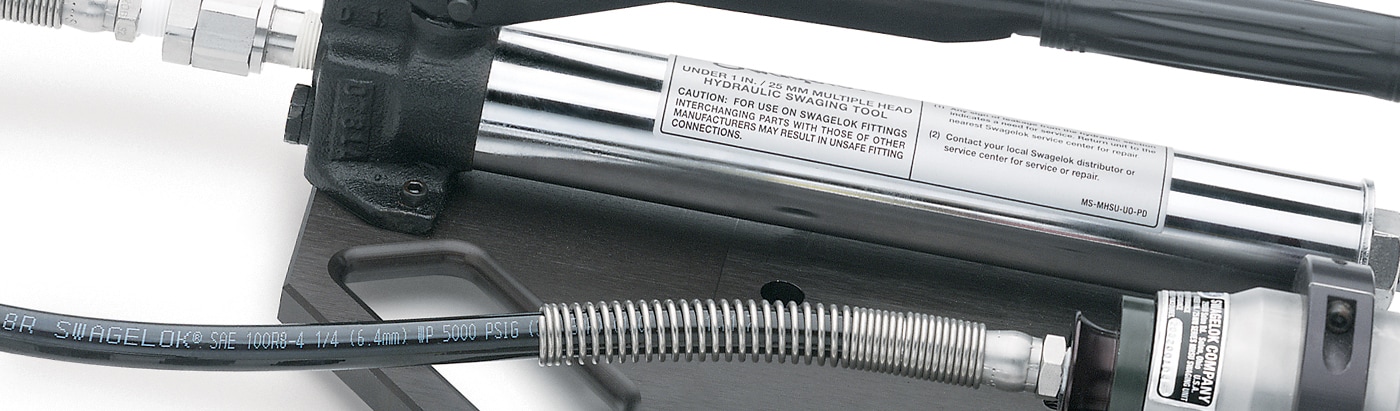

Swagelok® Multi-Head Swaging Units (MHSU)

Swagelok® multi-head swaging units (MHSU) streamline preswaging ferrules onto tubing, ensuring reliable connections. Ideal for high-volume applications, they reduce assembly time and operator error. MHSU units accommodate various tubing sizes without tools, making them versatile and user-friendly.

Get Help Selecting MHSUsSwagelok® multi-head swaging units (MHSU) are designed to streamline the preswaging process, ensuring reliable and efficient tubing connections. These units reduce assembly and installation time by preswaging ferrules onto tubing. A standard tube marking feature indicates when the tube is properly bottomed in the unit, enhancing accuracy and consistency. The MHSU is available in two sizes, with tooling for 1/2 to 1 inch and 12 to 25 mm tubing and tube adapters, as well as 1 to 2 inch and 25 to 50 mm tubing and tube adapters. Ideal for high-volume applications, these units minimize operator error and accommodate various tubing sizes without the need for additional tools, making them versatile and user-friendly.

Multi-Head Swaging Units Catalog

Locate detailed product information, including materials of construction, pressure and temperature ratings, options, and accessories.

Swagelok® tube fittings and tube adapters reduce the risk of costly system downtime with reliable tubing connections and are available in a variety of sizes and materials.

The Swagelok® Tube Fitting Advantage

Swagelok tube fittings are designed to meet your highest expectations for safety and dependability, featuring proven design, precise manufacturing, and superior raw materials.

Discover the AdvantageSwagelok Resources Curated for You

How to Avoid System Leaks: The Importance of Proper Tube Preparation

A successful tube fitting depends on many criteria, but one of the most important is proper tube preparation before installation. Learn to avoid costly or dangerous leaks by avoiding damaged, burred, or improperly cut tubes.

Case Study: Swagelok Helps Green Alternative Systems Control Labor Costs with Tube Bending Solutions

With Swagelok’s help testing ways to control labor costs, Green Alternative Systems (GAS) experienced a 75% reduction in production time—which translated into $224,000 in annual labor savings. Read more about how the collaboration paid off.

The Three T’s to Achieve an Intricate System of Tubing

Learn how the three T’s to using a hand tube bender can help you achieve an intricate system of tubing with fewer leak points and efficient flow.

How to Use a Swagelok Hand Tube Bender

Learn how to use a hand tube bender to accurately and efficiently make 90° and 180° bends in tubing. Swagelok® hand tube benders provide consistent, high-quality bends in tubing made from most materials used with Swagelok tube fittings.