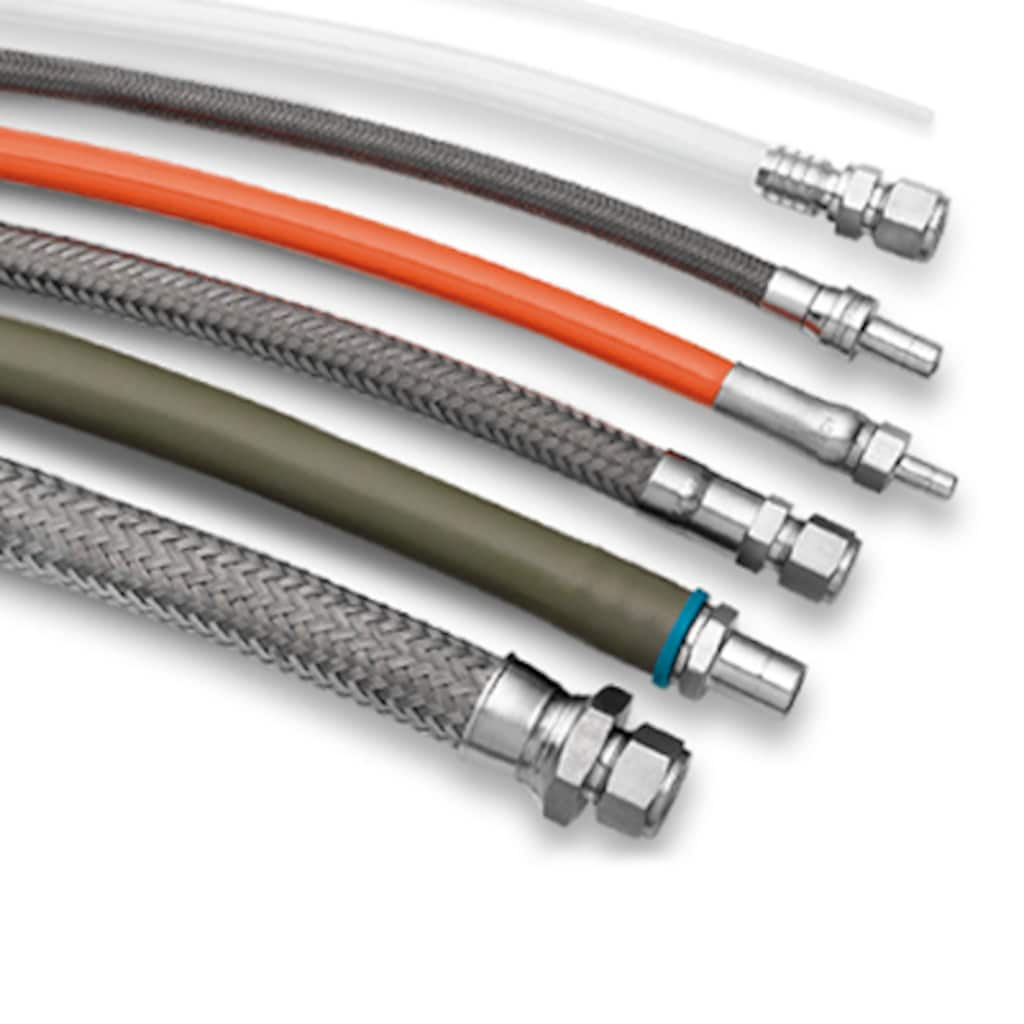

世伟洛克® 软管和柔性卡套管

世伟洛克提供具有各种内管材料、加固方式、端接和隔热选购件的—般工业软管和高纯度软管,以满足各种液体和气体输送需求。

软管 | 用于输送流体的多层柔性管道

柔性卡套管 | 用于输送流体的单层柔性管道

호스 및 플렉시블 튜빙 카테고리

Программа теплового контура

Откройте для себя новейшие разработки в области оптимизации тепловых контуров, производства полупроводниковых пластин, шлангов для охладителей и усовершенствований линий с помощью Swagelok.

Шланг с центральной трубкой из фторопласта (PTFE) и перфторалкокси (PFA)

- Шланг с центральной трубкой из перфторалкокси (PFA) и гладким каналом

- Шланги с гофрированной оболочкой из нерж. стали 316L и тефлоновой центральной трубкой с гладким каналом

- Шланги с тефлоновой центральной трубкой и гладким каналом, серия T

- 주름 없는 PTFE 코어 호스, B 시리즈

- 주름 없는 PTFE 코어 호스, F-시리즈

软管和柔性卡套管样本

世伟洛克提供尺寸为 1/8 至 2 in.可配多种英制和公制端接的软管,内管材料有金属、PTFE、热塑性塑料和橡胶。在这里提供的产品资料中查找详细的产品信息,包括结构材料、额定压力和温度、工具和附件以及诸如 ECE R110 认证和软管标签等选购件。

Swagelok® hose and tubing products are available in custom lengths, in diameters 2 inches and under, and with many types of end connections, core materials, and reinforcement styles to suit a broad spectrum of pressures and temperatures.

世伟洛克为您精心准备的产品、服务和解决方案

Des flexibles sûrs et des installations moins onéreuses en 3 étapes

Lors des opérations régulières de maintenance des installations, la sécurité des flexibles industriels est souvent négligée. Il est pourtant important de leur accorder la plus grande attention. Les fuites et l’usure de ces composants peuvent nuire au bon fonctionnement de vos installations. Découvrez des conseils pour éviter des situations dangereuses et diminuer vos coûts d’exploitation.

산업용 호스 유지보수 계획을 통해 플랜트의 비용을 대폭 절감하는 방법

산업용 호스의 적절한 교체 시기를 파악하는 것만으로도 플랜트의 유지보수 비용을 대폭 절감할 수 있습니다. 여러분의 시스템을 평가하고, 호스 수명을 관리할 수 있는 예방적 유지보수 계획을 개발하는 방법을 알아보십시오.

산업용 호스 교체: 코어 튜브 재질 고려 사항

산업용 호스를 선택할 때 첫 번째로 고려할 부분은 호스의 가장 안쪽 층인 코어 튜브입니다. Swagelok 전문가에게 코어 튜브 재질과 내벽 구조에 대한 정보와 함께 고객 애플리케이션에 이상적인 호스를 선정하는 방법을 배워보십시오.

최적의 호스 보강재 선택 방법

산업용 호스에는 일반적으로 수명과 성능 향상에 기여하는 핵심 보강층이 있습니다. 다양한 보강층의 종류와 서로 다른 유체 시스템 애플리케이션에 가장 적합한 종류가 무엇인지 알아보십시오.