Трубные обжимные фитинги и переходники Swagelok®

Снижение утечек и простоя оборудования благодаря трубным фитингам с двумя кольцами, обеспечивающие надежную герметичность, превосходный обхват трубки и устойчивость к вибрациям после сборки.

Трубные обжимные фитинги | Легкая установка, что снижает трудоемкость монтажа.

Трубные переходники| Предусматривают различные варианты соединений, помогают решить проблемы с совмещением.

Фитинги Swagelok превосходят конкурентов в области снижения риска утечек и дорогостоящих простоев в различных отраслях промышленности. Усовершенствованная конструкция заднего обжимного кольца обеспечивает защиту от напряжений, что препятствует вибрации, изгибу и прогибу, а запатентованный процесс науглероживания увеличивает прочность без ущерба для коррозионной стойкости. Фитинги Swagelok просты в монтаже и повторной сборке, требуя меньше трудовых затрат.

Трубные обжимные и соединительные фитинги выпускаются из различных сплавов для обеспечения химической совместимости, а для корректной установки предлагается обучение под руководством квалифицированных специалистов. Трубные переходники Swagelok можно использовать с любыми другими фитингами Swagelok, что избавляет от необходимости иметь в запасе специальные колена и тройники. Трубные фитинги Swagelok из нержавеющей стали, используемые с трубками из нержавеющей стали 316 и сплава 316 Ti, прошли испытания согласно требованиям ECE R110, а также обеспечены сертификатом EC-79. Компания Swagelok предлагает фитинги из материалов, соответствующих металлургическим требованиям стандартов NACE MR0175 / ISO 15156 и MR0103. Кроме того, изготовленные из сплавов 2507 и 6MO фитинги соответствуют требованиям NORSOK M-630 и M-650 в стандартном исполнении.

Категории трубных фитинги и переходников

Запасные части и вспомогательное оборудование

Подробнее о запасных частях и аксессуарах для трубных фитингов—передние и задние обжимные кольца, гайки, прокладки, уплотнительные кольца, щупы для контроля зазоров, гаечные ключи и многое другое.

Защитные фильтры

Узнайте больше о фитингах с защитным фильтром (т.н. протекторы дренажных отверстий), оснащенных проволочной сеткой для защиты от попадания в систему насекомых и других посторонних предметов.

Колпаки и заглушки

Колпачки и заглушки для трубных фитингов из различных материалов и разных размеров позволяет обеспечить герметичность и повышенную безопасность системы в широком диапазоне условий эксплуатации.

Муфты

Прямые муфты, и угловые отводы, тройники и крестовины из различных материалов и размеров обеспечивают необходимую опору и превосходную устойчивость к вибрации.

Муфты с малой застойной зоной

Трубные фитинги Swagelok® с малой застойной зоной разработаны для надежного повышения общей эффективности промышленных газовых и жидкостных систем, даже в жестких условиях эксплуатации.

Переходники с нулевым объемом

Ознакомьтесь с переходниками для трубных фитингов нулевого объема, разработанными с целью повышения общей эффективности вашей газовой или жидкостной системы.

Плавкие вставки

Плавкие трубные переходники улучшают общую безопасность промышленных газовых и жидкостных систем за счет сброса давления в атмосферу при заданной температуре.

Редуцирующие переходники

Переходные прямые отводы и тройники фитингов из различных материалов и обеспечивают простоту установки и возможность надежного контроля степени затяжки.

С монтажной гайкой

Трубные фитинги и переходники с монтажной гайкой делают возможным соединение через переборку, и предлагаются в различных размерах и типах соединения.

Соединители для проходного канала

Соединители Swagelok® для проходного канала обеспечивают соединение «фитинг в фитинг», промеряемость при начальном монтаже, легкость разъединения и повторной затяжки.

Соединители с внутренней резьбой

Доступные в различных материалах, размерах и конфигурациях фитинги на соединителях с внутренней резьбой обеспечивают герметичное уплотнение, устойчивое к вибрационной усталости.

Соединители с наружной резьбой

Доступные в различных материалах, размерах и конфигурациях фитинги на соединителях с наружной резьбой обеспечивают герметичное уплотнение, устойчивое к вибрационной усталости.

Трубные переходники

Прямые, угловые и тройниковые переходники обеспечивают соединение фитингов Swagelok® с различными типами торцевых соединений.

Фитинги под приварку враструб

Фитинги под приварку враструб обеспечивают необходимую соосность и центровку в системах малого диаметра. Предлагаем широкий ассортимент размеров и конфигураций для различных задач.

Каталоги трубных обжимных фитингов и переходников

Трубные обжимные фитинги и переходники Swagelok, рассчитанные на размеры трубок от 2 до 50 мм и от 1/16 до 2 дюймов и предлагаемые в разнообразных конфигурациях, изготавливаются из различных материалов, что обеспечивает превосходную коррозионную стойкость в широком спектре областей применения, включая химические процессы и высокосернистую газовую среду. Подробную информацию об изделии, включая используемые материалы, номинальные параметры давления и температуры, инструменты, вспомогательные принадлежности и инструкции по монтажу, можно найти в документации, представленной здесь.

The proven Swagelok® tube fitting design manufactured from corrosion-resistant alloy 2507 with NORSOK M0630 and M-650 compliance standard, NACE MR0175/ISO 15156 optional.

Приборные двух-, трех- и пятиклапанные блоки серий V, VB и VL; двух-, трех- и пятиклапанные блоки прямого монтажа серии VE; двухклапанные блоки выносного монтажа; модульные контрольно-измерительные системы Mod 85

Температура от 20 до 204 °C (от 70 до 400 ºF); Рабочее давление до 18,9 бара (275 фунтов на кв. дюйм, ман.); Размеры от 1/8 до 1/2 дюйма

Характеристики: пригодны для жидкостной и газовой хроматографии; конструкция из нержавеющей стали 316; предлагаются размеры от 1/16 до 1/2 дюйма.

Конструкция из нержавеющей стали, уплотнительное кольцо из фторуглерода FKM, Надежное повторяемое соединение, Предлагаются для трубок размером от 1/16 до 1 1/2 дюйма

Swagelok® tube fittings and tube adapters reduce the risk of costly system downtime with reliable tubing connections and are available in a variety of sizes and materials.

Размеры от 1/16 до 1 дюйма; Изготавливаются из нержавеющей стали марки 316, латуни и углеродистой сталиl; Резьбы NPT, ISO/BSP и SAE

Просмотр фитингов среднего и высокого давления

Ищете фитинги, выдерживающие давление свыше 11 000 psi? Изучите наши трубные обжимные фитинги среднего давления серии FK, рассчитанные на давление до 22 500 psi (1551 бар), и фитинги с конусом и резьбой, рассчитанные на давление до 60 000 psi (4134).

Найти более высокие номинальные параметры давленияРесурсы Swagelok специально для вас

Вводная информация о фитингах: Определение размера и шага резьбы

Даже у самых квалифицированных специалистов могут возникнуть трудности с определением резьбы. Менеджер по продукции Swagelok Энди Хичкок (Andy Hitchcock) объясняет, как определить размер и шаг резьбы на фитингах с помощью штангенциркуля, калибра шага и руководства по идентификации резьбы.

Оптимизация нефтегазовых систем среднего давления с помощью компрессионных фитингов

Узнайте, как компрессионные фитинги помогут увеличить скорость монтажа и обеспечить более высокие характеристики по сравнению с обычными соединениями с конусом и резьбой в системах среднего давления верхних строений в нефтегазовой отрасли.

Как группа компаний Shenyang Blower Works Group повысила уровень безопасности и надежности

Узнайте, как шанхайское подразделение Swagelok помогло группе компаний SBW обеспечить единообразие, надежность и экономию для клиентов и при этом повысить безопасность и эффективность собственного производства.

Как трубные переходники помогают решить проблемы с совмещением

Трубные переходники помогают решить проблемы с совмещением и сократить потребность в запасах запчастей. Посмотрите эту демонстрацию того, как использовать трубные переходники Swagelok® для решения проблем с совмещением и обеспечения герметичного уплотнения.

С 1947 года компания Swagelok является лидером в разработке трубных обжимных фитингов, используемых в промышленных жидкостных и газовых системах.

Основатель Swagelok рассказывает о своем революционном трубном обжимном фитинге

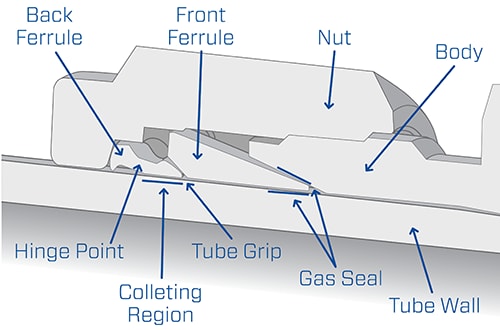

Более 75 лет спустя фитинги Swagelok с уникальным механизмом «шарнирно-цангового» действия по-прежнему обеспечивают длительную и герметичную эксплуатацию. Конструкция обжимного типа использует уникальное «шарнирно-цанговое» действие для получения оптимальных характеристик в трех следующих ключевых характеристиках:

Обхват трубки

Шарниро-цанговое действие обеспечивает более плотный контакт/обхват трубки.

Газонепроницаемость

Переднее обжимное кольцо полирует поверхность и создает концентрированные зоны контакта как на трубке, так и на корпусе фитинга для обеспечения качественного уплотнения.

Вибрационная устойчивость

Заднее обжимное кольцо обеспечивает защиту от концентрации напряжений в зоне обхвата трубки при воздействии на соединение изгибающих напряжений, деформации или вибрации.

Конструкция трубного обжимного фитинга Swagelok®

Шарнирно-цанговая конструкция заднего обжимного кольца с усовершенствованной геометрией является стандартной для всех трубных обжимных фитингов Swagelok из нержавеющей стали размером от 1/4 до 1 дюйма (6-25 мм), что позволяет монтажникам создавать единообразные и герметичные трубные соединения. Для данных размеров запатентованы процедура закалки корпуса и сложная геометрическая форма углубления, которые обеспечивают уникальную конструкцию заднего обжимного кольца Swagelok. Шарнирно-цанговая конструкция заднего обжимного кольца улучшает характеристики и без того надежной традиционной конструкции обжимного кольца.