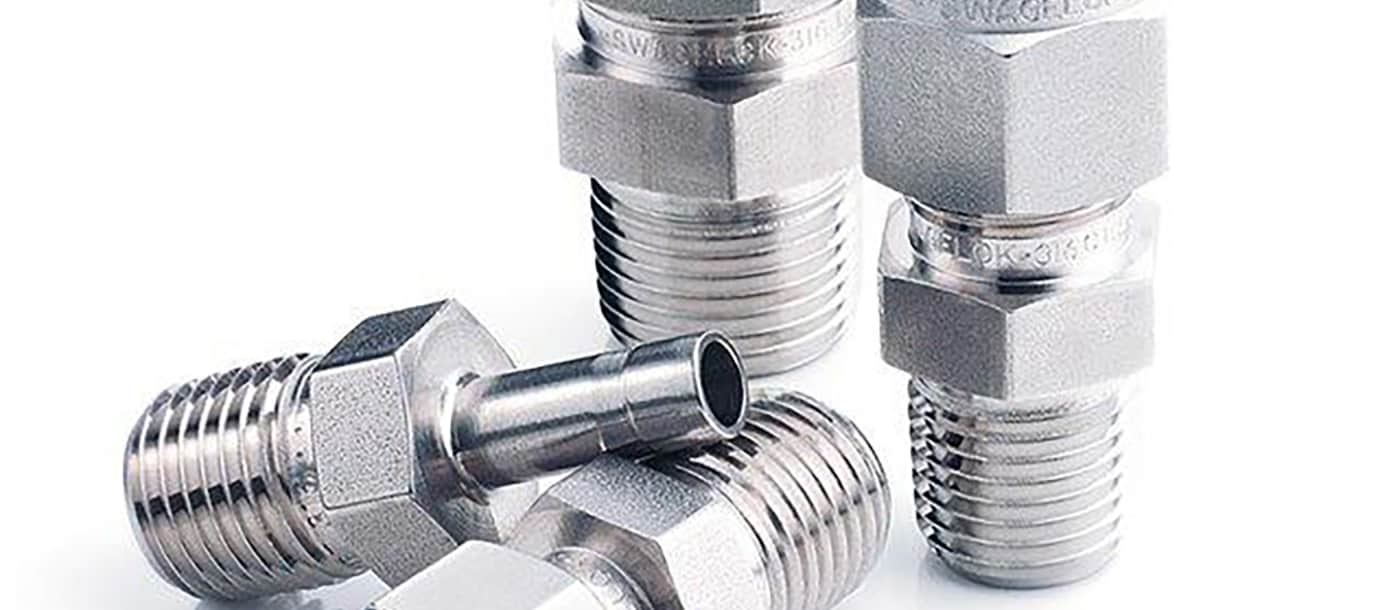

High Purity PFA Fine Thread Flare Fittings

Swagelok® PFA fine thread flare fittings provide safe, efficient fluid system operation in high-purity applications. They are ideal for the use in semiconductor production and aggressive chemical environments.

Get Help Selecting PFA Flare FittingsSwagelok® PFA fine thread flare fittings are made from molded fluoropolymer. These fittings provide tensile strength, resistance to permeation, thermal stability, and maintain leak-tight connections in demanding fluid systems. Swagelok PFA fittings are compatible with other ultrahigh-purity products, including valves and tubing, to create a fully integrated system suitable for handling aggressive fluids. The fittings are available in a range of shapes and sizes, such as straight, elbow, and tee configurations. Depending on application needs, they are offered with standard PFA bodies and PVDF nuts, or all-PFA and all-PVDF configurations.

Specifications

| Pressure Ratings | Up to 275 psig (18.9 bar) |

| Temperature Ratings | 75 to 350°F (23 to 176°C) |

| Body | High-purity PFA |

| Nuts | PVDF (standard), PFA (optional) |

| End Connection | Sizes: 1/8 to 1 in. Configurations: Straights, elbows, tees, caps, plugs, nuts, PVDF fittings |

High Purity PFA Fine Thread Flare Fitting Catalogs

Locate detailed product information, including materials of construction, pressure and temperature ratings, options, and accessories.

■ チューブ外径サイズ:1/4 インチ、3/8 インチ、1/2 インチ、3/4 インチ、1 インチ/■ ナット材質:PVDF(標準)、PFA(オプション)/■ 豊富な種類の形状

An Introduction to Fittings: Identifying Thread Size and Pitch

Even the most seasoned professionals can experience difficulty identifying threads. Swagelok product manager Andy Hitchcock explains how to identify thread size and pitch on your fittings using a caliper, pitch gauge and thread identification guide.

Read About Fitting SelectionSwagelok Resources Curated for You

Zuverlässige Fluidsystemlösungen für die Wissenschaft

Erfahren Sie mehr darüber, warum sich das finnische Unternehmen Bluefors bei der Herstellung seiner Mischungskryostate für Anwendungen in den Bereichen Quantum-Computing und Experimentalphysik auf die Fluidsystemkomponenten und -lösungen von Swagelok verlässt.

Profitablere Halbleiterwerke bauen

Erfahren Sie, wie der Einsatz qualitativ hochwertiger Fluidsystemkomponenten und deren Installation den Bau Ihrer Halbleiterfertigungsanlage beschleunigen und die Gesamtbetriebskosten über die Lebensdauer der Anlage senken kann.

最適な合金で半導体製造の歩留まりを高める

重要な流体システム部品に適した金属材料を選定することで、エンドからエンドまでの製造の歩留まりを高め、長期的な収益性の向上を図る方法を紹介します。

Q&A:半導体製造の過去・現在・将来

半導体装置メーカー、マイクロデバイス・メーカー、流体システム・ソリューションのプロバイダーが連携することで、数十年間にわたっていかにして半導体市場はムーアの法則の要求に追いつくことができたのでしょうか。これからの展望と併せて紹介します。