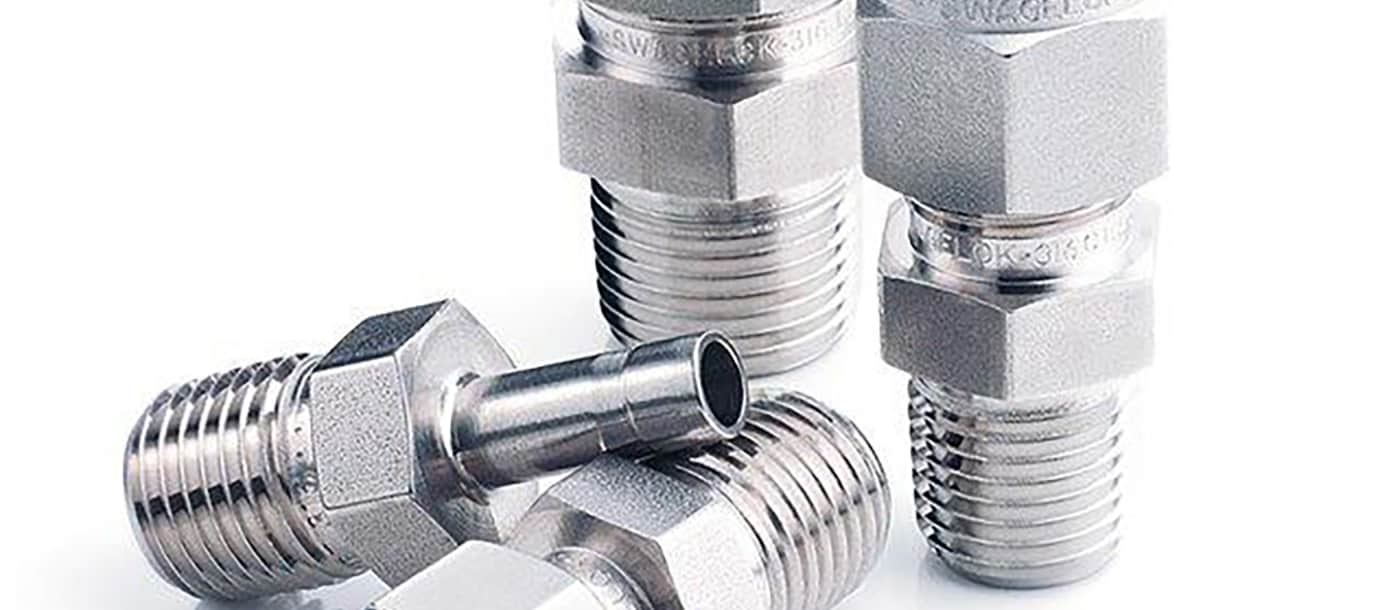

고순도 PFA 가는 나사 확관(Flare) 피팅

Swagelok® PFA 가는 나사 확관(Flare) 피팅은 고순도 애플리케이션에서 안전하고 효율적인 유체 시스템 작동을 보장합니다. 이 제품은 반도체 생산과 부식성 화학 환경에서 사용하기에 이상적입니다.

PFA 확관(Flare) 피팅 선택에 도움 받기Swagelok® PFA 가는 나사 확관(Flare) 피팅은 주조 플루오르수지(fluoropolymer)로 제조됩니다. 이 피팅은 인장 강도, 투과 내성, 온도 안정성을 제공하며, 까다로운 유체 시스템에서 누설 없는 연결을 유지합니다. Swagelok PFA 피팅은 밸브 및 튜빙을 포함한 다른 초고순도 제품과 호환되므로, 부식성이 강한 유체를 취급하는 데 적합한 완전 일체형 시스템을 구축할 수 있습니다. 이 피팅은 직선형, 엘보우, 티 구성과 같이 폭넓은 형상과 크기로 공급 가능합니다. 또한, 애플리케이션 요건에 따라, 표준 PFA 몸체 및 PVDF 너트와 함께 또는 전체 PFA 및 전체 PVDF 구성으로 공급됩니다.

사양

| 압력 등급 | 최대 275psig(18.9bar) |

| 온도 등급 | 23~176°C(75~350°F) |

| 몸체 | 고순도 PFA |

| 너트 | PVDF(표준), PFA(옵션) |

| 연결구 | 크기: 1/8~1인치 구성: 직선형, 엘보우, 티, 캡, 플러그, 너트, PVDF 피팅 |

고순도 PFA 가는 나사 확관(Flare) 피팅 카탈로그

구성 재질, 압력 및 온도 등급, 옵션, 액세서리를 포함한 자세한 제품 정보를 찾을 수 있습니다.

Предлагаются для трубок размером 1/4, 3/8, 1/2, 3/4 дюйма и 1 дюйм; Варианты исполнения гаек из перфторалкокси (PFA) и поливинилиденфторида (PVDF); Широкий выбор конфигураций

피팅 소개: 나사 크기 및 피치 식별

경력이 많은 전문가도 가끔 나사산을 확인하기 어려울 때가 있습니다. Swagelok 제품 매니저 Andy Hitchcock이 캘리퍼, 피치 게이지, 나사산 식별 가이드를 통해 피팅의 나사산 크기와 피치를 확인하는 방법을 설명합니다.

피팅 선정에 대해 알아보기고객별 맞춤 선별 Swagelok 리소스

첨단 과학 분야에 필요한 신뢰성 높은 유체 시스템 솔루션

핀란드의 희석 냉동기 제조업체인 블루포스(Bluefors)가 양자 컴퓨팅과 실험물리학 등을 구현하는 데 Swagelok의 유체 시스템 부품과 솔루션을 신뢰하는 이유를 소개합니다.

더 수익성 높은 반도체 제조 시설 구축

고품질 유체 시스템 부품 및 어셈블리 선택이 반도체 제조 시설의 더 빠른 건설과 시설 수명 동안 총 소유 비용 감소에 기여할 수 있는 이유를 알아보십시오.

최적의 합금으로 반도체 수율 향상

반도체 제조업체가 어떻게 하면 핵심 유체 시스템 부품에 적절한 합금을 선택하여 종합적인 생산 수율과 장기 수익성을 높일 수 있는지 알아보십시오.

Q&A: 반도체 제조의 과거와 현재, 그리고 미래

반도체 장비 OEM, 마이크로칩 제조업체, 유체 시스템 솔루션 제공업체가 어떻게 지난 몇십 년 동안 협력을 통해 반도체 시장이 무어의 법칙에 따른 수요를 충족하도록 해왔으며, 이제부터는 어떻게 해야 할 것인지 알아보십시오.