Gleitringdichtungssysteme von Swagelok®

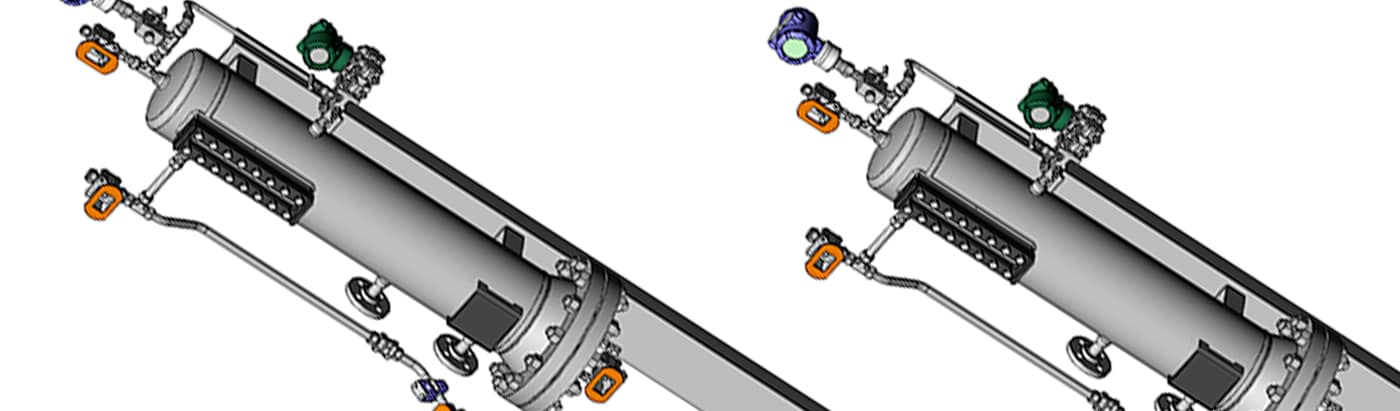

Swagelok bietet professionell ausgelegte Gleitringdichtungssysteme, die einfach zu installieren und zu warten sind. Sie sind die ideale Lösung, um einen zuverlässigen, effizienten und sicheren Betrieb Ihrer rotierenden Anlagenteile zu gewährleisten. So verringern Sie nicht nur Ausfallzeiten und Kosten, sondern sparen auch wertvolle Zeit.

Sie brauchen Unterstützung bei der Auswahl des richtigen Systems?Die Bausätze und Baugruppen für Gleitringdichtungssysteme von Swagelok sind gemäß den Anforderungen nach API 682 angeordnet und sorgen so für ein zuverlässiges und einfach zu installierendes System, das das Leckagerisiko durch Vermeidung von Rohrgewinden und eine geringe Anzahl von Verbindungsstellen minimiert. Für eine erleichterte Montage werden die Bausätze für atmosphärische Seitenpläne und Prozessseitenpläne zusammen mit den technischen Zeichnungen gemäß API-Richtlinien geliefert. Die Bausätze enthalten auch technische Informationen für Anwender, damit diese einen Überblick haben, an welchen Stellen die Rohrleitung gebogen werden sollte, um das Risiko potenzieller Leckagen weiter einzudämmen.

Swagelok bietet individuelle Baugruppen für Dichtungspläne. Diese umfassen speziell auf die jeweilige Anwendung abgestimmte Schalttafeln und Tauchbehälter. Pläne für den Raum zwischen den Dichtungen und Baugruppen für Prozessseitenpläne sind mit oder ohne Installationsset erhältlich. Die von Swagelok auf höchste Zuverlässigkeit ausgelegten Systeme verfügen zur Vermeidung von Lufteinschlüssen über hoch gelegene Entlüftungsöffnungen und zur sicheren Entleerung über tief gelegene Ablassöffnungen. Außerdem wurden Druck-/Temperaturmesspunkte zur Ermittlung und Behebung von Störungen vorgesehen. Leicht zugängliche Filter, Siebe und Bypass-Leitungen sorgen für einen guten Durchfluss und anpassbare Konfigurationen mit Absperr- und Entlüftungsventilen und 2-Wege-Ventilblöcken für mehr Sicherheit.

Mehr über Gleitringdichtungssysteme erfahren

Spezifikationen

| Dichtungsplan-Bausätze (Seal Plan Kits, SPK) | Pläne für die Prozessseite: API 11, API 12, API 13, API 14, API 21, API 22, API 23, API 31 und API 41 Pläne für die Atmosphärenseite: 51, 62, 65A und 65B |

| Dichtungsplan-Baugruppen (Seal Plan Assemblies, SPA) | Plan für die Prozessseite gemäß API 32 Pläne für den Raum zwischen den Dichtungen gemäß API 52, API 53A, API 53B, API 53C, API 54, API 55, API 72, API 74, API 75, API 76 und API 72/76 |

| Auslegungsdruck | 720 psig / 49.6 bar |

| Anschlussgrößen | 3/8 bis 3/4 Zoll; NPT |

| Anschlusstypen | Verschraubungen mit Innen- und Außengewinde, erweiterte Verschraubungen mit Außengewinde |

| Rohrgrößen | 6–25 mm (1/4–1 Zoll) |

Überblick zu unseren Anwendungsleitfäden

Detaillierte Informationen zu unseren Baugruppen anfordern

Dichtungssysteme werden jeweils für eine bestimmte Gleitringdichtung und eine Reihe von Prozessbedingungen entwickelt. Diese Systeme liefern entweder Gas oder eine Flüssigkeit zu den Gleitringdichtungen, um die Umgebung zu kontrollieren, in der die Dichtung eingesetzt wird und um rotierende Geräte vor Schaden zu schützen. Swagelok-Gleitring-Dichtungssysteme stützen sich auf die Anleitungen von API 682: Pumpen - Achsendichtungssysteme für Zentrifugal- und Kreiselpumpen.

Individuelle Lösungen für alle Branchen

Erfahren Sie, wie wir Sie bei der Konstruktion und Montage Ihrer Fluidsysteme in bewährter Swagelok-Qualität unterstützen können, damit Sie wertvolle Zeit einsparen und von einem optimiertem Systembetrieb profitieren.

Unsere Experten unterstützen Sie gerneRessourcenzentrum

API 682 für Anwender: Optimierung von Gleitringdichtungssystemen

Erfahren Sie mehr über die Empfehlungen des API-Standard 682 zur Auslegung und Installation von Gleitringdichtungssystemen und die Best Practices für langlebige und leistungsstarke Systeme.

Gleitringdichtungssysteme im Fokus

Erfahren Sie mehr darüber, wie die Gleitringdichtungssysteme von Swagelok® für die Auslegung gemäß API 682 wertvolle Best Practices in sich vereinen und warum sie sich aufgrund ihrer Konfiguration durch eine einfache Montage und Instandhaltung auszeichnen.

Wie Sie bei der Herstellung von Fluidsystemen ressourcenbedingte Einschränkungen minimieren können

Ein erfolgreicher und zuverlässiger Anlagenbetrieb steht und fällt mit den verwendeten Fluidsystemen. Wenn die Ressourcen knapp sind, kann sich die Beteiligung eines kompetenten Fertigungspartners schnell bezahlt machen.

Field Engineers im Interview: Wie unser Global Engineering Team Ihnen dabei helfen kann, die Leistung Ihrer Fluid- und Probenahmesysteme zu verbessern

Unsere Field Engineers unterstützen Betreiber von Fluid- und Probenahmesystemen bei der Lösung ihrer Probleme—von Leckagen bis hin zu Ungenauigkeiten bei der Probenahme. In diesem Artikel erfahren Sie alles, was Sie über die Services der Field Engineers bei Swagelok wissen sollten.