Редукторы давления Swagelok®, куполовидные

Универсальные (серия SGRD) и высокочувствительные (серия SHRD) куполовидные редукторы давления хорошо подходят для систем, где требуется ручное или дистанционное управление устройством, и точный контроль заданного давления.

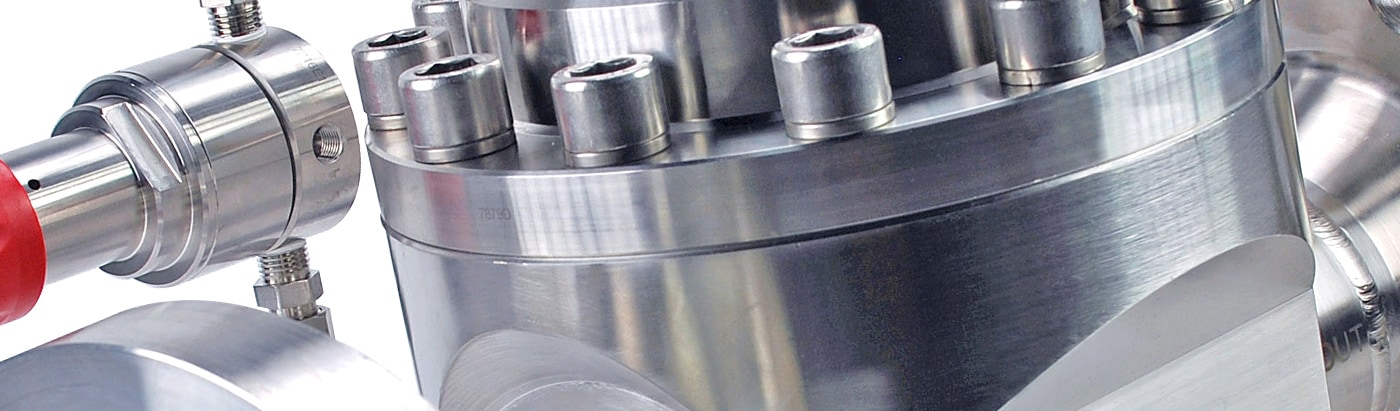

Помощь с выбором технологических регуляторовРегуляторы серий SGRD и SHRD рассчитаны на долгую работу в сложных условиях. Корпуса регуляторов изготовлены из нержавеющей стали 316L, что повышает их коррозионную стойкость и долговечность. Предусмотрены внутренние уплотнения из различных материалов, которые обеспечивает повышенную совместимость с широким спектром химических веществ и режимов давления.

Куполовидные редукторы давления обеспечивают превосходные характеристики для поддержания стабильного давления на выходе. Благодаря использованию купола вместо пружины, такие устройства эффективно минимизируют перепад давления. Их конструкция обеспечивает постоянное давление на выходе, независимо от колебаний входного давления или изменения расхода.

Характеристики серий SGRD и SHRD

- Конструкция с уравновешенным золотником

- Мембранный чувствительный механизм

- Без выпуска

- Управление пилотным регулятором

Настраиваемые характеристики

- Внешняя обратная связь к пилотному регулятору

- Пилотное устройство перепада давления (серия SGRD)

- Двухступенчатый пилотный регулятор (серия SGRD)

- Защита от несанкционированного доступа / Рукоятка пилотного устройства с заводскими настройками

- NACE MR0175/ISO 15156

Редукторы давления общего назначения, купольные регуляторы (серия SGRD)

Технические характеристики

| Размер корпуса | Максимальное давление на входе, psig (бар ман) | Максимальное давление на выходе, psig (бар ман) | Диапазон регулируемого давления psig (бар ман) | Тип чувствительного механизма psig (бар ман) | Рабочая температура, °F° (C) | Коэффициент расхода (Cv) | Минимальная масса, фунты (кг) |

|---|---|---|---|---|---|---|---|

| 12 | 6000 (413) | 6000 (413) | 5–6000 (0,3–413) | Мембранный: 5–6000 (0,3–413) | от –49 до 356° (от –45 до 180°) | 2,3 | 9,7 (4,4) |

| 16 | 4,8 | 26,5 (12,0) | |||||

| 24 | 10,7 | 27,6 (12,5) |

Высокочувствительные редукторы давления, купольные регуляторы (серия SHRD)

Технические характеристики

| Размер корпуса | Максимальное давление на входе, psig (бар ман) | Максимальное давление на выходе, psig (бар ман) | Диапазон регулируемого давления psig (бар ман) | Тип чувствительного механизма psig (бар ман) | Рабочая температура, °F° (C) | Коэффициент расхода (Cv) | Минимальная масса, фунты (кг) |

|---|---|---|---|---|---|---|---|

| 12 | 250 (17,2) | 250 (17,2) | 1–250 (0,07–17,2) | Мембранный: 1–250 (0,07–17,2) | от –49 до 356° (от –45 до 180°) | 2,3 | 9,7 (4,4) |

| 16 | 4,8 | 26,5 (12,0) | |||||

| 24 | 10,7 | 27,6 (12,5) |

Каталог технологических куполовидных редукторов давления

Получите подробные сведения о продукции, в том числе о материалах изготовления, номинальных параметрах давления и температуры, вариантах исполнения и вспомогательных принадлежностях.

Модели редукторов давления, Модели регуляторов обратного давления, Подпружиненные, куполовидные и пневматические, Торцевые соединения от 1/4 до 4 дюймов, Рабочее давление до 700 бар (10 150 фунтов на кв. дюйм, ман.), Температура от -20 до 80 °C (от –4 до 176 °F)

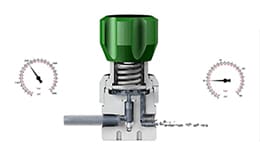

A pressure regulator has a sensing element (piston or diaphragm) which, on one side, is subjected to a load force (FS) created by a spring (as shown below) or gas pressure. On the other side, the sensing element is subject to the force (F) of the system fluid.

Нужна помощь с выбором подходящего регулятора?

Сравните показатели разных регуляторов в различных рабочих условиях с помощью нашего калькулятора для расчета параметров расхода регулятора.

Поиск подходящего регулятораРесурсы Swagelok специально для вас

Минимизация эффекта нагнетаемого давления (SPE) в регуляторе

Эффект нагнетаемого давления—это обратная зависимость между значениями давления на входе и выходе регулятора. Узнайте, как минимизировать это явление в регуляторах давления благодаря рекомендациям от компании Swagelok.

Как тщательные испытания гарантируют надежность работы регулятора

Вы когда-нибудь задавались вопросом, какие испытания проходят изделия, предназначенные для работы в экстремальных условиях? Загляните в лабораторию и узнайте историю разработки промышленных регуляторов серии RHPS для эксплуатации при сверхнизких температурах.

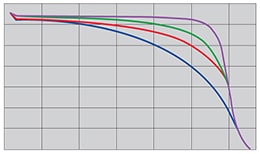

Как выпрямить кривую расхода регулятора для уменьшения падения давления

Потеря давления является проблемой для каждого редуктора. Узнайте, как свести к минимуму такой эффект и выпрямить кривую расхода с помощью целого ряда вариантов куполовидных регуляторов.

Применение регулятора для уменьшения временной задержки в аналитической контрольно-измерительной системе

Временную задержку в аналитических системах часто недооценивают или неправильно интерпретируют. Одним из способов уменьшить эту задержку является регулятор, управляемый давлением среды. Изучите эти рекомендации, чтобы узнать, как уменьшить временную задержку в аналитической системе.