Swagelok®減圧レギュレーター、ドーム・ロード式

一般産業用(SGRDシリーズ)および高感度(SHRDシリーズ)のドーム・ロード式減圧レギュレーターは、レギュレーターの手動操作または遠隔操作、および正確な設定圧力の制御が必要な各種産業アプリケーションに適しています。

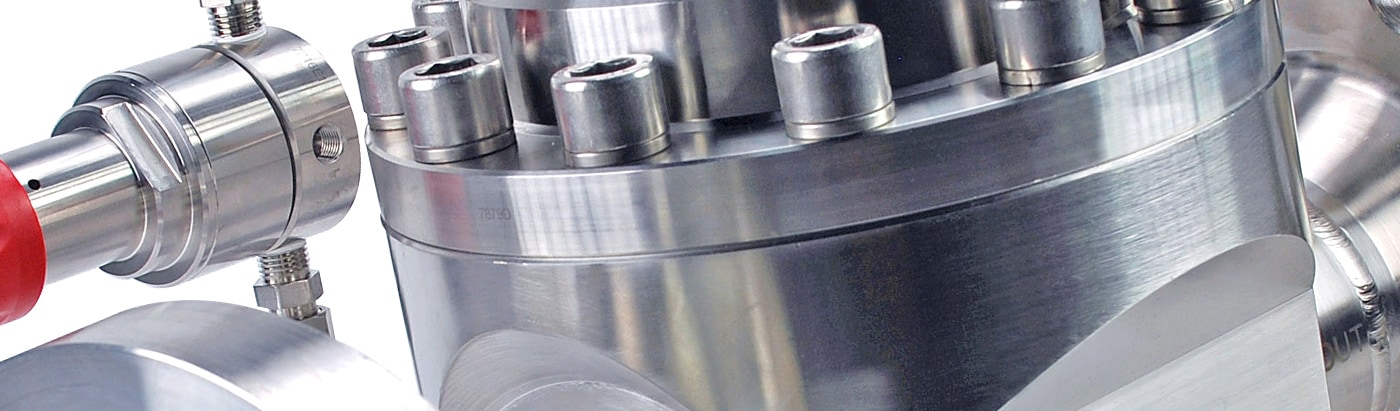

プロセス・レギュレーター選定のサポートを依頼するSGRDシリーズおよびSHRDシリーズ・レギュレーターは、過酷な環境における耐久性に優れています。ボディ材質に316Lステンレス鋼を採用することで、耐食性および耐久性を高めています。両レギュレーターの内部シールは、さまざまな材質から選ぶことができ、幅広い化学薬品や圧力条件への適合性が向上しています。

ドーム・ロード式減圧レギュレーターは、安定した二次側圧力の維持において、優れたパフォーマンスを発揮します。設定スプリングの代わりに圧力ドームを利用して制御することで、効率的にドループ(流量増加に伴う二次側圧力の降下)を最小限に抑えます。これで一次側圧力または流量の変動に関わらず、安定した二次側圧力を得ることができます。

SGRDシリーズ/SHRDシリーズの特徴

- バランス型ポペット

- 感知メカニズム・タイプ:ダイヤフラム

- ベント機能なし

- パイロット・レギュレーター調整

オプション(カスタマイズ可能)

- パイロットへの外部フィードバック

- 差圧パイロット(SGRDシリーズ)

- 二段式パイロット(SGRDシリーズ)

- 誤操作防止/工場取り付けパイロット・ハンドル

- NACE MR0175/ISO 15156

一般産業用ドーム・ロード式減圧レギュレーター(SGRDシリーズ)

仕様

| ボディ・サイズ | 一次側の最高使用圧力(MPa) | 二次側の最高調整圧力(MPa) | 調整圧力範囲(MPa) | 感知メカニズム・タイプ(MPa) | 使用温度範囲(°C) | 流量係数(Cv値) | 最小質量(kg) |

|---|---|---|---|---|---|---|---|

| 12 | 41.3 | 41.3 | 0.034~41.3 | ダイヤフラム:0.034~41.3 | –45~180° | 2.3 | 4.4 |

| 16 | 4.8 | 12.0 | |||||

| 24 | 10.7 | 12.5 |

高感度ドーム・ロード式減圧レギュレーター(SHRDシリーズ)

仕様

| ボディ・サイズ | 一次側の最高使用圧力(MPa) | 二次側の最高調整圧力(MPa) | 調整圧力範囲(MPa) | 感知メカニズム・タイプ(MPa) | 使用温度範囲(°C) | 流量係数(Cv値) | 最小質量(kg) |

|---|---|---|---|---|---|---|---|

| 12 | 1.72 | 1.72 | 0.006~1.72 | ダイヤフラム:0.006~1.72 | –45~180° | 2.3 | 4.4 |

| 16 | 4.8 | 12.0 | |||||

| 24 | 10.7 | 12.5 |

ドーム・ロード式減圧レギュレーターのカタログ

構成部品とその材質、使用圧力、使用温度、オプション、アクセサリーなど、製品に関する詳細情報を確認することができます。

Swagelok RHPS series deliver precise pressure control in process fluid systems up to 4 in. (101 mm) in a variety of spring-, dome-, and air-loaded pressure regulators.

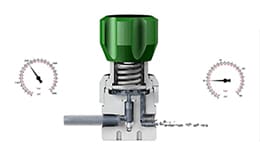

A pressure regulator has a sensing element (piston or diaphragm) which, on one side, is subjected to a load force (FS) created by a spring (as shown below) or gas pressure. On the other side, the sensing element is subject to the force (F) of the system fluid.

適切なレギュレーターを選定するのにサポートが必要ですか?

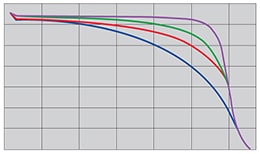

レギュレーター流量曲線作成ツールを使用すると、さまざまなアプリケーション条件におけるレギュレーターのパフォーマンスを比較することができます。

適切なレギュレーターを探すスウェージロックのリソース

レギュレーターの供給圧力影響(SPE)に対処する

レギュレーター内部における一次側圧力の変化と二次側圧力の変化は、供給圧力影響(SPE)または依存性による反比例の関係にあります。今回は、圧力レギュレーターで発生する供給圧力影響(SPE)による現象への対処方法を紹介します。

レギュレーターの信頼性を確保するために

過酷な条件下での運用を前提とした製品には、どのような試験を行うべきでしょうか。今回は、スウェージロックの実験室における取り組みと共に、氷点下を大幅に下回る温度でも正常に機能する一般産業用RHPSシリーズ・レギュレーターの開発事例を紹介します。

レギュレーターの流量曲線を平坦にしてドループを抑える方法

ドループ(流量増加に伴う二次側圧力の降下)は、あらゆるレギュレーターに共通する問題です。今回は、ドループを最小限に抑えてレギュレーターの流量曲線を平坦にする方法を、さまざまなドーム・ロード式レギュレーターの構成と併せて紹介します。

レギュレーターを使用して分析計装システムにおける時間遅れを短縮する方法

分析システムでは、時間遅れが軽視されていたり、誤解されていたりするケースは少なくありません。この時間遅れは、レギュレーターでコントロールすることができます。今回は、分析計装システムにおける時間遅れを小さくする方法を紹介します。