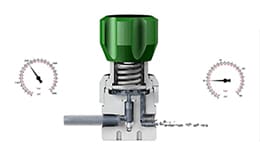

Swagelok®ガス・ボンベ切り替え用レギュレーター

KCMシリーズ・レギュレーターは、ガス供給源を自動的に切り替えることで継続したガス供給を実現し、ダウンタイム(停止時間)を削減します。

レギュレーターの選定サポートを依頼する重要な一般産業アプリケーションにおいて、Swagelok ガス・ボンベ切り替え用 レギュレーター KCMシリーズを使用して、ひとつのガス供給源から別の供給源へ自動的に切り替えることで、継続したガス供給を実現し、ダウンタイム(停止時間)および人件費を削減することができます。KCMシリーズ・レギュレーターは、最小限のメンテナンスで信頼性の高いガス供給を実現します。コンボルーティッド非せん孔型ダイヤフラムを使用しているため、耐久性および圧力応答性に優れています。

仕様

| 一次側の最高使用圧力 | 30.0 MPa(PEEK製シートの場合) 24.8 MPa ボンベとの接続部やホースのアクセサリーによっては、最高使用圧力が低下する場合があります。 |

| 二次側の圧力調整範囲 | 0~0.068 MPaから0~3.44 MPa |

| 公称切り替え圧力 | 0.68 MPa、1.72 MPa、3.44 MPa |

| 流量係数(Cv値) | 0.06 |

| 最高使用温度 | 80°C(PCTFE製シートの場合) 200°C(PEEK製シートの場合) 100°C(PEEK製シートで、一次側の最高使用圧力が24.8 MPaを超える場合) |

ガス・ボンベ切り替え用レギュレーターのカタログ

ガス・ボンベ切り替え用レギュレーターの構成部品とその材質、アクセサリー、使用圧力、使用温度など、製品に関する詳細情報につきましては、以下の資料をご参照ください。

関連資料/コラム記事

レギュレーターの供給圧力影響(SPE)に対処する

レギュレーター内部における一次側圧力の変化と二次側圧力の変化は、供給圧力影響(SPE)または依存性による反比例の関係にあります。今回は、圧力レギュレーターで発生する供給圧力影響(SPE)による現象への対処方法を紹介します。

レギュレーターの信頼性を確保するために

過酷な条件下での運用を前提とした製品には、どのような試験を行うべきでしょうか。今回は、スウェージロックの実験室における取り組みと共に、氷点下を大幅に下回る温度でも正常に機能する一般産業用RHPSシリーズ・レギュレーターの開発事例を紹介します。

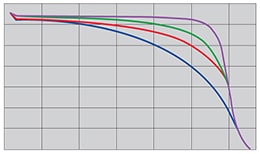

レギュレーターの流量曲線を平坦にしてドループを抑える方法

ドループ(流量増加に伴う二次側圧力の降下)は、あらゆるレギュレーターに共通する問題です。今回は、ドループを最小限に抑えてレギュレーターの流量曲線を平坦にする方法を、さまざまなドーム・ロード式レギュレーターの構成と併せて紹介します。

Comment utiliser un détendeur pour réduire le temps de réponse d’un système d’instrumentation analytique

Le temps de réponse d’un système d’analyse est souvent sous-estimé ou mal compris. L’utilisation d’un détendeur permet de réduire ce temps de réponse. Découvrez comment maîtriser le temps de réponse de votre système d’analyse grâce à ces conseils.