Swagelok® 튜브 피팅 및 어댑터

재조립 후에도 누설 없는 밀폐 성능, 탁월한 튜브 그립, 진동 내성을 제공하는 2-페럴 튜브 피팅으로 누설과 가동 중단을 줄여 보십시오.

튜브 피팅 | 설치가 간편하므로 설치 작업자의 피로를 줄일 수 있습니다.

튜브 어댑터 | 다양한 연결구를 지원하며 까다로운 정렬 문제를 해소하는 데 유용합니다.

Swagelok 피팅은 다양한 산업 전반에서 다른 제품에 비해 누설 위험과 많은 비용을 초래하는 가동 중단을 줄이는 데 뛰어납니다. 첨단 후위 페럴 구조는 응력을 격리하여 진동, 굽힘, 변형에 견딜 수 있으며, 특허 기술인 탄화 공정으로 내식성 저하 없이 강도가 보강되었습니다. 설치와 재조립이 쉬운 Swagelok 피팅은 다른 제품보다 필요한 노력이 더 적습니다.

튜브 피팅과 어댑터 피팅은 화학적 호환성을 보장할 수 있도록 다양한 합금으로 공급되며, 올바른 설치에 필요한 전문가 강의 교육이 제공됩니다. Swagelok 튜브 어댑터는 다른 어떤 Swagelok 튜브 피팅과도 함께 사용할 수 있으므로 전용 엘보우 및 티를 비축할 필요가 없습니다. 316 스테인리스강 및 316 Ti 스테인리스강 합금 튜빙과 함께 사용되는 스테인리스강 Swagelok 튜브 피팅은 ECE R110 요구 사항에 따른 테스트를 거쳤으며 EC-79 인증 제품도 공급 가능합니다. Swagelok은 NACE MR0175/ISO 15156 및 MR0103의 금속공학적 요구 조건을 충족하는 재질의 피팅을 공급합니다. 또한, 2507 및 6MO 합금으로 제조된 피팅은 기본적으로 NORSOK M-630 및 M-650 규격을 준수합니다.

튜브 피팅 및 튜브 어댑터 카테고리

튜브 피팅 및 어댑터 카탈로그

1/16~2인치 및 2~50mm 튜브 크기와 다양한 구성으로 공급되는 Swagelok 튜브 피팅과 튜브 어댑터는 케미칼 가공 및 Sour 가스를 포함한 광범위한 애플리케이션에서 탁월한 내부식성을 제공하는 다양한 재질로 제조됩니다. 여기에 있는 제품 자료에서 구성 재질, 압력 및 온도 등급, 공구 및 액세서리, 설치 지침을 포함한 자세한 제품 정보를 확인하실 수 있습니다.

The proven Swagelok® tube fitting design manufactured from corrosion-resistant alloy 2507 with NORSOK M0630 and M-650 compliance standard, NACE MR0175/ISO 15156 optional.

계장용, 직접 장착형, 원거리 장착형 매니폴드 및 모듈식 시스템 , V, VB 및 VL 시리즈 2-, 3- 및 5-밸브 계장용 매니폴드, VE 시리즈 2-, 3- 및 5-밸브 직접 장착형 매니폴드, 2-밸브 원거리 장착형 매니폴드, Mod 85 모듈식 계장용 시스템

Features: Temperatures from 70 to 400°F (20 to 204°C); Working pressures up to 275 psig (18.9 bar); Sizes from 1/8 to 1/2 in.

Features: Suitable for liquid or gas chromatography; 316 stainless steel construction; Offered in sizes from 1/16 to 1/2 in.

스테인리스강 구조, 탄화플루오르 FKM O-링; 안정적이고 반복 가능한 밀폐 성능; 1/16 ~ 1 1/2 in. 인치 튜브 크기 제공

1/16 in. 부터 2 in. 및 2 mm 에서 50 mm; 최초 설비 시 일관된 측정가능성; 분리 및 재조립이 용이함; 다양한 재질 및 형태

중압 및 고압 피팅 둘러보기

11,000psi가 넘는 압력을 다룰 수 있는 피팅을 찾고 계십니까? 최대 22,500psi(1,551bar)의 애플리케이션에 사용 가능한 Swagelok FK 시리즈 중압 튜브 피팅과, 최대 60,000psi(4,134bar)의 애플리케이션에 사용 가능한 콘 & 쓰레드 피팅에 대해 읽어보십시오.

더 높은 압력 등급 찾기고객별 맞춤 선별 Swagelok 리소스

피팅 소개: 나사 크기 및 피치 식별

경력이 많은 전문가도 가끔 나사산을 확인하기 어려울 때가 있습니다. Swagelok 제품 매니저 Andy Hitchcock이 캘리퍼, 피치 게이지, 나사산 식별 가이드를 통해 피팅의 나사산 크기와 피치를 확인하는 방법을 설명합니다.

압축 피팅으로 중압 오일 및 가스 애플리케이션 최적화하기

오일 및 가스 상부설비(topside asset)의 중압 애플리케이션에서, 기존 콘 & 쓰레드 연결구에 비해 압축 피팅이 어떻게 설치 속도와 성능 면에서 이점을 제공할 수 있는지 알아보십시오.

선양 고풍기 유한공사(Shenyang Blower Works Group)의 안전 및 신뢰성 개선 사례

선양 고풍기 유한공사(Shenyang Blower Works Group)가 안전과 생산 효율성을 개선하는 동시에, 일관성, 신뢰성, 고객 비용 절감을 실현할 수 있도록 Swagelok Shanghai가 어떻게 지원했는지 알아보십시오.

튜브 어댑터로 정렬 문제를 해결할 수 있는 이유

튜브 어댑터를 통해 까다로운 정렬 위치 문제를 해결하는 동시에 재고를 줄일 수 있습니다. Swagelok® 튜브 어댑터를 사용하여 정렬 문제를 해결하고 누설 없는 밀폐 성능을 제공하는 방법을 이 데모에서 확인하십시오.

1947년 이래로 Swagelok은 거의 모든 산업 분야의 산업용 유체 시스템에 사용되는 튜브 피팅 기술을 발전시켜온 선두 주자입니다.

Swagelok 설립자가 자신의 혁신적인 튜브 피팅에 대해 설명합니다

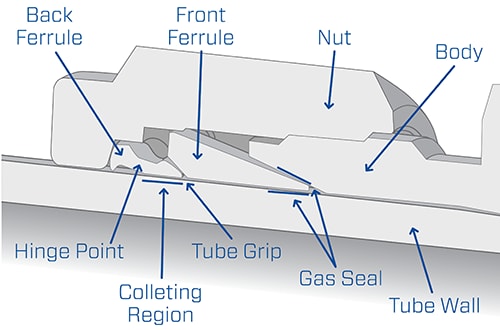

75년 이상이 지난 후에도, Swagelok 튜브 피팅은 고유한 “힌지-콜릿” 작동 방식으로 오래 지속되는 누설 없는 서비스를 제공하는 것으로 신뢰성을 유지하고 있습니다. 그립(Grip) 방식 디자인은 “힌지-콜릿(hinging and colleting)” 작동 방식을 활용하여 다음 세 가지 영역에서 최적의 성능을 달성합니다.

튜브 그립

힌지-콜릿 작동 방식은 더 직접적인 튜브 접촉/그립 지지 성능을 제공합니다.

가스 밀폐

전위 페럴의 버니싱/연마(burnishing/polishing) 작용으로 튜브 및 몸체 베벨에 집중적인 접촉 구역이 형성되어 더 강력한 밀폐 성능을 제공합니다.

진동 내성

콜릿 영역은 튜브 그립에서 응력 증가 지점을 더 잘 차단하므로 굽힘, 변형, 진동이 억제됩니다.

Swagelok® 튜브 피팅 구조

모든 Swagelok 6~25mm(1/4~1인치) 스테인리스강 튜브 피팅에는 첨단 기하학적 구조의 힌지-콜릿(hinging-colleting) 후위 페럴 설계가 표준으로 적용되어 있으므로, 설치업체가 더 일관적으로 누설 없는 튜브 연결을 만들 수 있습니다. 이 크기에서, Swagelok 후위 페럴은 특허 기술인 표면 경화 공정과 특허를 받은 요철 형태의 기하학적 구조로 특별한 엔지니어링 이점을 제공합니다. 힌지-콜릿(hinging-colleting) 후위 페럴 설계는 기존 페럴의 입증된 높은 성능을 한층 더 강화합니다.