Swagelok® 레귤레이터

산업용 압력 레귤레이터는 유체 시스템의 안전한 사용을 보장하는 데 필수입니다. Swagelok 압력 레귤레이터는 안전하고 비용 효율적인 유체 시스템 운영에 필요한 일관적이고 정확한 성능을 제공합니다. 국제적 전문가와 현장 전문 인력들과 함께, Swagelok은 핵심 애플리케이션에서 압력을 최적화하는 데 필요한 고품질 제품과 필수 지식을 모두 제공함으로써 전 세계 산업 전문업체에 신뢰성과 지원을 보장합니다.

요구 조건에 최적의 레귤레이터 찾기Swagelok 압력 레귤레이터는 산업 전문업체에 일관적이고 정확하며 오래 지속되는 성능을 제공합니다. Swagelok 레귤레이터는 타협 없는 품질에 대한 Swagelok의 명성을 유지할 수 있도록 엄격한 표준에 따라 설계, 제조, 조립, 테스트를 거칩니다. Swagelok의 포괄적인 레귤레이터 포트폴리오를 통해 다양한 유량에 걸쳐 압력을 효율적으로 관리하고, 유체 시스템 운영에서 안전, 신뢰성, 비용 효율성을 촉진할 수 있습니다.

Swagelok 제품 라인에는 테스트 환경의 정밀 제어용 분석 및 계장 레귤레이터(K 시리즈), 대규모 산업 애플리케이션용 프로세스 압력 레귤레이터(프로세스 레귤레이터 및 RHPS 시리즈), 청정 공정용 고순도 대유량 레귤레이터(HF 시리즈), 샘플 준비용 기화 감압 레귤레이터(KEV 및 KSV 시리즈), 연속 가스 유동용 가스 실린더 전환 레귤레이터(KCM 시리즈), 위험 유체 보관 환경의 안전 확보용 탱크 블랭킷 레귤레이터가 포함됩니다.

산업 전문업체는 올바르지 못한 제품 선정으로 인한 압력 제어 문제에 흔히 직면합니다. Swagelok 자문가들은 부품 크기 선정, 재질 선택, 현장 문제 해결, 시스템 설계 지원 등을 도울 수 있는 기술적 전문 지식을 보유하고 있습니다. 이를 통해 가압 유체 시스템의 신뢰성 높은 운영을 보장할 수 있습니다. Swagelok의 포괄적인 레귤레이터 제품군과 전문적인 지원을 통해 고객은 목표를 확실하게 달성할 수 있습니다.

Regulators Categories

Back-Pressure Regulators, Dome-Loaded

Safeguard complex systems' sensitive equipment by controlling varying inlet and upstream pressures despite varying flow demands.

Back-Pressure Regulators, Spring-Loaded

Precisely control inlet pressure, ensuring consistent process output and performance across various industrial applications.

High-Purity, High-Flow Gas Regulators, HF Series

Design systems more efficiently with manual adjustability, high-flow capacity, and a corrosion-resistant design for dependable gas control.

Pressure-Reducing Regulators, Dome-Loaded

Achieve precise and consistent control over pressure fluctuations, irrespective of variations in flow rate or inlet pressure.

Pressure-Reducing Regulators, Spring-Loaded

Maintain process outputs within chemical distribution, DI water, and chemical delivery systems with the right pressure-reducing, spring-loaded regulator.

Pressure-Reducing Regulators, Electrically-Heated

Enhance accuracy and stability with an electrically heated vaporizing pressure-reducing regulator, ideal for vaporizing liquid samples or preheating gas samples.

Steam-Heated Vaporizing Pressure-Reducing Regulators

Explore cutting-edge vaporizing pressure reducing regulators at Swagelok. Achieve precise pressure control with our diverse product range.

Gas Cylinder Changeover Regulators

Ensure safe and efficient gas supply with our high-quality gas cylinder regulators and changeover regulators. Trust us for reliable gas control solutions!

Tank Blanketing Pressure Regulators

Explore Swagelok's tank blanketing regulator solutions for precise pressure control and reliable gas management in industrial processes.

Ramp Regulators

Discover Swagelok’s hydrogen pressure regulator for refueling stations. Learn how this hydrogen gas regulator ensures safe, precise pressure control.

Spare Parts and Accessories

Maintain regulators and reduce downtime with OEM rebuild kits. Kits include wetted components, lubricant, and instructions.

레귤레이터 카탈로그

분석 또는 계장 환경에서 다운스트림 또는 업스트림 압력을 유지해야 하는 경우(K 시리즈) 또는 까다로운 산업 환경에서 압력을 제어하려는 경우(RHPS 시리즈), 고순도 대유량 애플리케이션(HF 시리즈) 또는 위험한 유체가 담긴 저장 탱크를 사용하는 시스템(탱크 블랭킷)을 막론하고 스웨즈락은 고객 요구에 부합하는 구성을 제공합니다. 여기에 있는 제품 자료에서 구성 재질, 압력 및 온도 등급, 옵션, 액세서리 등 자세한 제품 정보를 찾으실 수 있습니다.

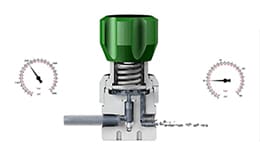

A pressure regulator has a sensing element (piston or diaphragm) which, on one side, is subjected to a load force (FS) created by a spring (as shown below) or gas pressure. On the other side, the sensing element is subject to the force (F) of the system fluid.

Swagelok offers pressure-reducing and vapor recovery (back-pressure) tank blanketing regulators for systems requiring an inert gas in the vapor space of a storage tank.

Features: Compact size with flow rates up to 200 std L/min; Maximum inlet pressures up to 500 psig (34.4 bar); Manually adjustable outlet pressure up to 150 psig (10.3 bar); 316L VIM-VAR stainless steel body for ultrahigh-purity applications; 1/4 in. VCR® metal face seal; 1/4 in. tube butt weld; 1.5 in. and 1.125 in. C-seal and W-seal modular surface-mount end connections

Swagelok® HF series are high-flow, high-purity pressure regulators available in compact preset or dome-loaded models with flow rates up to 300 std L/min.

Swagelok RHPS series deliver precise pressure control in process fluid systems up to 4 in. (101 mm) in a variety of spring-, dome-, and air-loaded pressure regulators.

Swagelok offers pressure-reducing, back-pressure, dome-loaded, and spring-loaded pressure regulators to control pressure and minimize droop in instrumentation systems.

최적의 레귤레이터를 선정하는 데 도움이 필요하십니까?

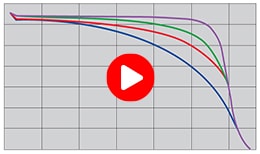

Swagelok 레귤레이터 유량 곡선 생성기 도구를 사용하여 다양한 애플리케이션에서 서로 다른 레귤레이터의 성능을 비교해보십시오.

최적의 레귤레이터 찾기고객별 맞춤 선별 Swagelok 리소스

레귤레이터 내 공급-압력 효과(SPE) 관리

공급-압력 효과(SPE)란 의존성이라고도 부르며, 레귤레이터의 입구 압력과 출구 압력 변화 사이의 반비례 관계를 의미합니다. Swagelok이 제공하는 팁을 통해 압력 레귤레이터에서 이러한 현상을 관리하는 방법을 알아보십시오.

드룹(Droop)을 최소화하는 방법

드룹(Droop) 즉, 다운스트림 유량이 증가함에 따른 출구 압력 감소는 모든 레귤레이터에서 문제가 될 수 있습니다. 이 비디오를 보고 감압 레귤레이터에서 드룹(Droop)을 최소화하려면 고려해야 할 사항을 알아보십시오.

가열식 레귤레이터(KEV 시리즈) 솔루션 소개

신뢰도 높은 Swagelok® 분석 샘플링 시스템용 가열식 레귤레이터( KEV 시리즈)가 어떻게 작업자 입력, 주변 온도, 기타 작동 조건의 변화에 대응하여 일관적이고 신뢰도 높은 성능을 제공하는지 알아보십시오.

분석 계장 시스템에서 레귤레이터를 사용하여 시간 지연을 줄이는 방법

시간 지연 문제는 종종 분석 시스템에서 과소 평가되거나 오해를 받습니다. 이러한 문제를 완화하는 방법 중 하나는 압력 제어 레귤레이터를 사용하는 것입니다. 이러한 팁을 통해 분석 시스템의 시간 지연 문제를 관리하는 방법을 알아보십시오.

실험실 벤치에서 바쁜 제조 시설과 상업용 충전소에 이르기까지, 산업용 압력 레귤레이터는 유체를 최적의 압력으로 보관하고 운반하는 데 핵심적인 역할을 합니다. 이러한 애플리케이션에서 압력을 적절하게 제어할 수 없다면, 테스트 결과가 유효성을 상실하거나, 공정이 중단되거나, 장비가 손상되거나, 인력이 위험에 처할 수 있습니다. 시스템에 있는 레귤레이터가 잦은 유지보수, 수리 또는 교체 없이 긴 작동 수명 동안 일관적이고 정확하게 압력 수준을 유지할 수 있는지 파악해야 합니다.

Swagelok 압력 레귤레이터는 유체 시스템을 안전하고, 신뢰성 높으며, 비용 효율적으로 운영하는 데 필요한 일관적이며 정확하고 오래 지속되는 성능을 제공합니다.

레귤레이터의 성능 알아보기

스프링 하중, 돔 하중 또는 기타 사용 가능한 수많은 레귤레이터 구성 중에서 선택하는 과정을 현지에서 지원할 수 있는 유체 시스템 자문가들이 Swagelok의 전 세계 공인 판매 및 서비스 센터에 포진하고 있습니다. 이 자문가들은 또한 레귤레이터 문제를 진단하고 가스 분배 시스템과 같이 레귤레이터가 포함된 유체 시스템을 맞춤 구성하고 제작하는 업무도 지원할 수 있습니다.