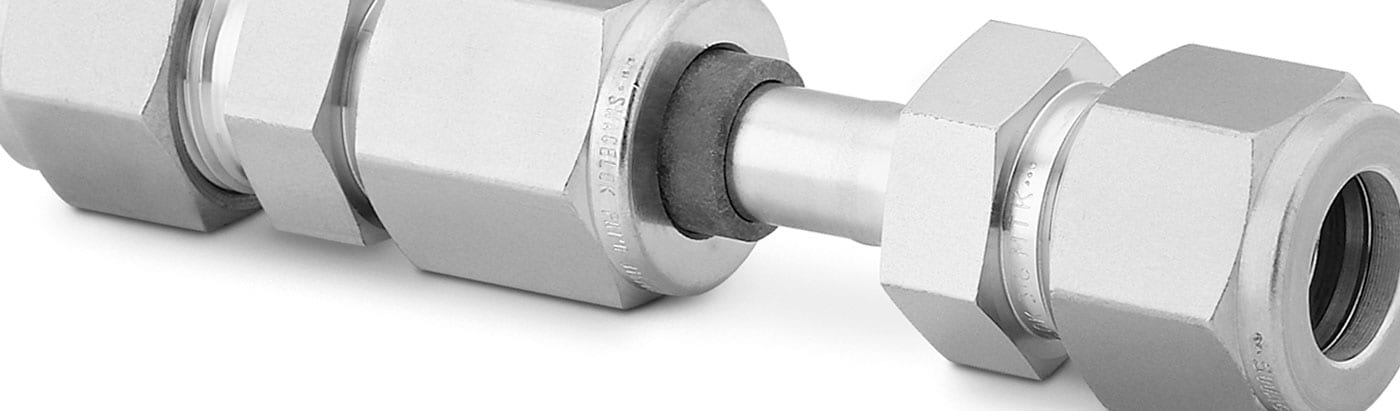

Dielektrische Verschraubungen von Swagelok®

Mit den dielektrischen Verschraubungen von Swagelok lassen sich Messgeräte unter Beibehaltung eines vollen Durchflusses gegen die Einflüsse von elektrischem Strom absichern. Das sorgt nicht nur für höchste Genauigkeit der Messgeräte, sondern spart auch Kosten ein, die anderenfalls für den Austausch beschädigter Geräte aufgewendet werden müssten.

Dielektrische Verschraubungen anzeigenFür einen optimalen Schutz von Geräten sind die dielektrischen Verschraubungen von Swagelok so konstruiert, dass die beiden Primärfunktionen—elektrische Isolierung und Fluideindämmung—voneinander getrennt sind. Die thermoplastische Isolation zeichnet sich durch eine hohe Widerstandskraft gegen elektrische, chemische und ultraviolette Einflüsse aus und die geringe Wasserabsorption sorgt für eine höchste Durchschlagsfestigkeit und Integrität über einen weiten Bereich von Betriebs- und Klimabedingungen hinweg.

Die Verschraubungen werden häufig in Erdgas-Pipelines auf Impulsleitungen vor Überwachungsstationen installiert und unterbrechen den Kathodenstromfluss bei gleichzeitig vollem Durchfluss. Prüflehrenfähige Swagelok®-Rohrverschraubungen oder kegelige Gewindeendanschlüsse (NPT/BSP) ermöglichen einen direkten Anschluss an Präzisionsrohr- oder Rohrsysteme. Dies sorgt für kürzere Montagezeiten.

Haben Sie Fragen zu dielektrischen Verschraubungen?

Dielectric Fitting Categories

Unions

Isolate and protect monitoring instruments from the effects of electrical current while still permitting full fluid flow with Swagelok® dielectric fittings.

Dielektrische Verschraubungen—Kataloge

Hier finden Sie ausführliche Produktinformationen zu Werkstoffen, Drücken und Temperaturen, Optionen und Zubehör.

Features: Metal components are machined from 316 stainless steel for use in rugged environments; Molded thermoplastic insulation with excellent electrical, chemical, and ultraviolet resistance and low water absorption maintains dielectric strength and integrity over a wide range of operating and climatic conditions; Gaugeable Swagelok® tube fitting or tapered pipe thread end connections (NPT/BSP) provide direct connection to tubing or piping system.

Vorteile der Rohrverschraubungen von Swagelok®

Die Rohrverschraubungen von Swagelok erfüllen dank ihrer bewährten Auslegung, der präzisen Herstellung und hochwertiger Werkstoffe selbst die höchsten Anforderungen in Sachen Sicherheit und Zuverlässigkeit.

Vorteile entdeckenRessourcenzentrum

Verschraubungen—eine Einleitung: Ermittlung der Größe und Steigung von Gewinden

Selbst erfahrene Experten haben manchmal Schwierigkeiten damit, Gewinde eindeutig zu bestimmen. Erfahren Sie von Andy Hitchcock, Product Manager bei Swagelok, wie Sie die Gewindegröße und -steigung Ihrer Verschraubungen mithilfe von Messschieber, Gewindeschablone und Gewindeidentifikationshilfe ermitteln.

Holen Sie mit Klemmringverschraubungen mehr aus Ihren Öl- und Gasanlagen heraus

Informieren Sie sich über unsere Klemmringverschraubungen für Offshore-Öl- und Gasanlagen mit mittlerem Druck und welche Vorteile diese gegenüber Konus-/Gewindeverschraubungen im Hinblick auf Installationszeiten und Leistung bieten.

Wie die Shenyang Blower Works Group von sicheren und zuverlässigeren Prozessen profitiert

Erfahren Sie in diesem Beitrag, wie Swagelok Shanghai der Shenyang Blower Works Group Corporation dabei geholfen hat, gleichbleibend hochwertige, zuverlässige und kosteneffiziente Lösungen für Kunden zu entwickeln und dabei gleichzeitig die eigene Sicherheit und Produktionseffizienz zu optimieren.

Swagelok Tube Fitting Installation

This video demonstrates the integral steps for installing Swagelok tube fittings, which have earned a global reputation for consistency, quality, and reliability.