システム設計者およびユーザーは、製品カタログの内容をすべてご覧になった上で、安全な製品の選定を行ってください。 安全にトラブルなく機能するよう、システム全体の設計を考慮して、製品をご選定ください。 機能、材質の適合性、数値データなどを考慮し製品を選定すること、また、適切な取り付け、操作およびメンテナンスを行うのは、システム設計者およびユーザーの責任ですので、十分にご注意ください。

Warning: Do not mix/interchange Swagelok products or components not governed by industrial design standards, including Swagelok tube fitting end connections, with those of other manufacturers.

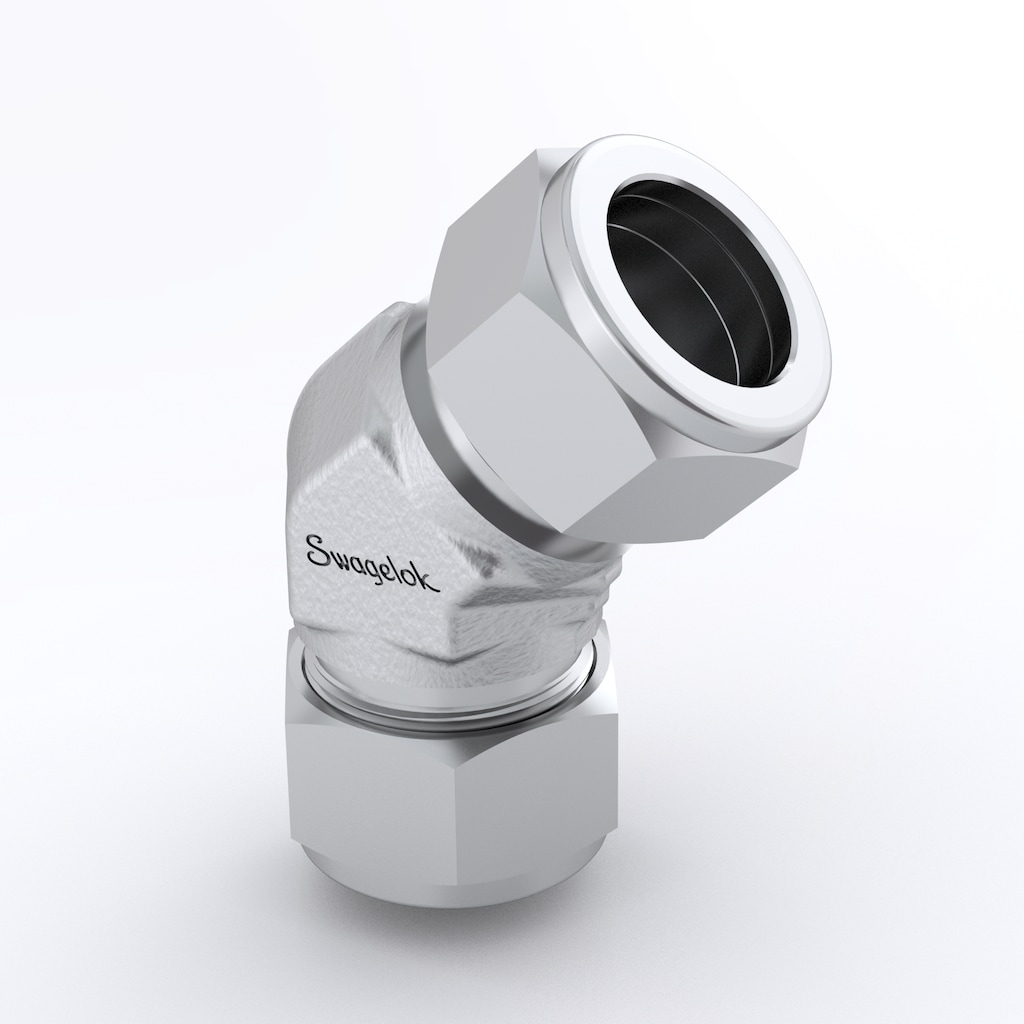

Stainless Steel Swagelok Tube Fitting, 45° Union Elbow, 3/4 in. Tube OD

Log in or Register to view price

Catalogs

45° Elbows

Achieve leak-tight performance with a robust tube grip and vibration resistance. The remarkable dependability of the Swagelok tube fitting has been proven with over 65 years of success, and has been documented in numerous published test reports, including those performed under extreme conditions.

Swagelok® tube fittings and tube adapters reduce the risk of costly system downtime with reliable tubing connections and are available in a variety of sizes and materials.

Swagelok's Snoop liquid leak detector exposes gas leaks while pipe thread sealants SWAK, PTFE and PTFE-free tape and thread lubricant Goop can help prevent future leaks.

Features: Step-by-step identification procedure for threads and end connections.

Find information about tubing selection, handling, and installation as well as suggested allowable working pressure tables with elevated temperature factors for several metal alloys.

This document specifies guidelines used by Swagelok® Company and its suppliers to ensure compliance with product cleanliness requirements as stated in ASTM G93 Level C. Application of the document is limited to wetted system components. This document must be used in conjunction with product catalogs, technical bulletins, and reports.

Swagelok® Specification SC-10 defines the cleaning, lubrication, assembly, and packaging requirements for standard Swagelok products and describes practices used to meet these requirements.

Specifications

| Attribute | Value |

|---|---|

| Body Material | 316 Stainless Steel |

| Bored Through | No |

| Cleaning Process | Standard Cleaning and Packaging (SC-10) |

| Connection 1 Size | 3/4 in. |

| Connection 1 Type | Swagelok® Tube Fitting |

| Connection 2 Size | 3/4 in. |

| Connection 2 Type | Swagelok® Tube Fitting |

| Flow Restrictor | No |

| eClass (4.1) | 37020715 |

| eClass (5.1.4) | 37020501 |

| eClass (6.0) | 37020501 |

| eClass (6.1) | 37020501 |

| UNSPSC (4.03) | 40141718 |

| UNSPSC (10.0) | 40142606 |

| UNSPSC (11.0501) | 40142604 |

| UNSPSC (13.0601) | 40183101 |

| UNSPSC (15.1) | 40183101 |

| UNSPSC (17.1001) | 40183101 |

Resources

Drawings

Two-dimensional renderings are available for this product. Download the CAD file.

Three-dimensional renderings are available for this product. Download the CAD file.

Sales drawings are available for this product. Download the files.

Similar Products

|

Part #

|

Body Material

|

Connection 1 Size

|

Connection 1 Type

|

Connection 2 Size

|

Connection 2 Type

|

|

|---|---|---|---|---|---|---|

| SS-400-95 | 316 Stainless Steel | 1/4 in. | Swagelok® Tube Fitting | 1/4 in. | Swagelok® Tube Fitting | View Product |

| SS-810-95 | 316 Stainless Steel | 1/2 in. | Swagelok® Tube Fitting | 1/2 in. | Swagelok® Tube Fitting | View Product |

お問い合わせ

本製品に関するご質問は、担当のスウェージロック指定販売会社までお問い合わせください。指定販売会社は、投資を最大限に活用するためのアドバイスも提供いたします。